Transformation method of two-section rubber diaphragm sealed gas cabinet

A rubber membrane, two-stage technology, which is applied in the field of transformation of two-stage rubber membrane sealed gas cabinets, can solve the problems of complex construction process organization, piston drift, and high construction accuracy requirements, and achieves short construction organization and construction period. The effect of fast running speed and convenient construction organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

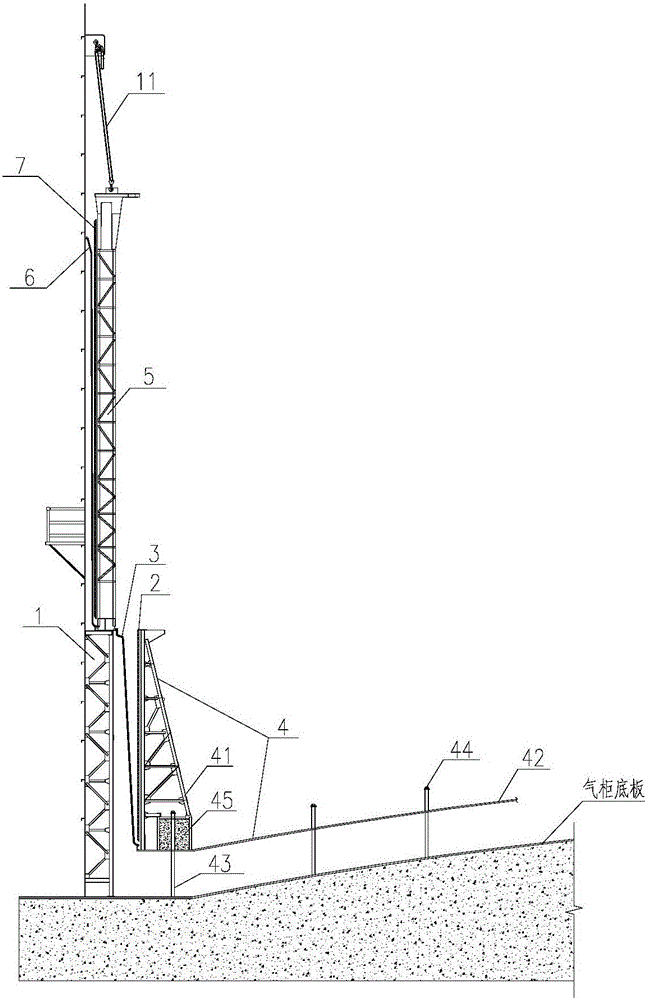

[0033] Such as figure 1 As shown, the existing two-stage rubber membrane sealed gas cabinet includes a cabinet body, a piston 4 and a T baffle 5, and a T baffle stand 1 is arranged in the cabinet; the piston 4 includes a piston fence 41 and a piston bottom plate 42; the piston and the T baffle Piston fence corrugated board 2 and piston fence rubber film 3 are arranged between plate frame 1; T baffle rubber film 6 and T baffle corrugated board 7 are arranged between T baffle 5 and cabinet body; piston ring is arranged under the piston Beam temporary support 43 and piston temporary support 44 .

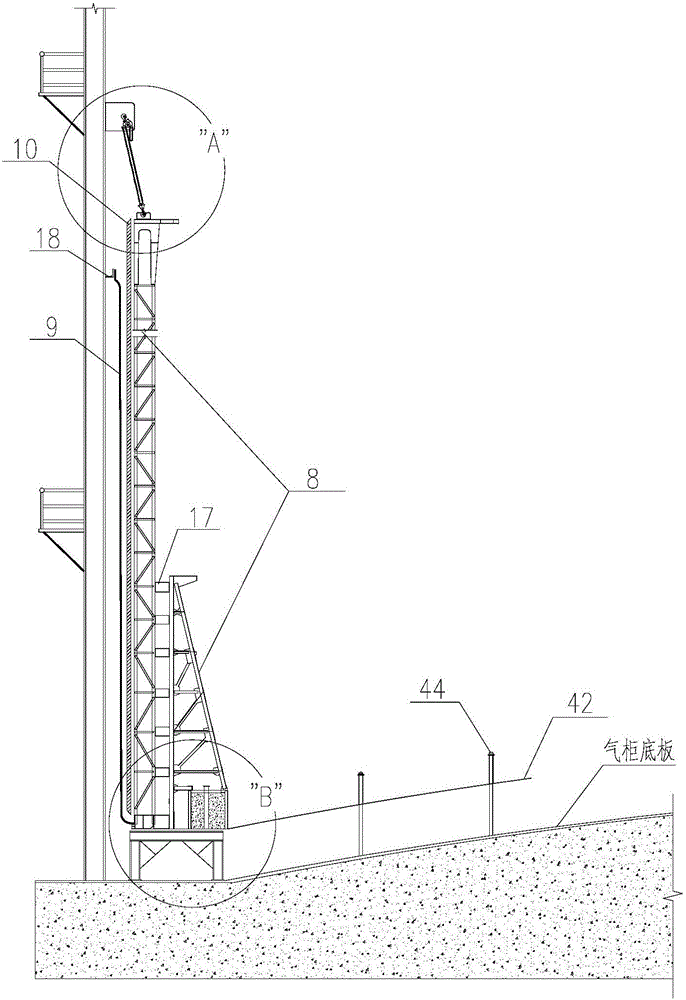

[0034] Such as Figure 2-3 As shown, the transformation method of the two-stage rubber membrane-sealed gas cabinet in this embodiment makes full use of the main structure and auxiliary process facilities of the original two-stage rubber-membrane-sealed gas cabinet to maintain the two-stage rubber-membrane-sealed gas cabinet The piston fence 41, the piston temporary support 44 and the ...

Embodiment 2

[0043] On the basis of the foregoing embodiments, a preparatory step is also included before said step one: stop production of the gas holder and perform gas replacement, and cut construction holes on the cabinet side plate of the two-stage rubber membrane sealed gas holder; in step five After that, it also includes the finishing process: sealing the construction holes on the gas cabinet body.

[0044] The construction hole is cut on the side plate of the cabinet body in this embodiment, so that construction personnel can enter and exit through the construction hole, and materials and tools can be transported through the construction hole, which can greatly save the time for workers to enter and exit and transport materials and tools, and is conducive to speeding up construction. schedule.

Embodiment 3

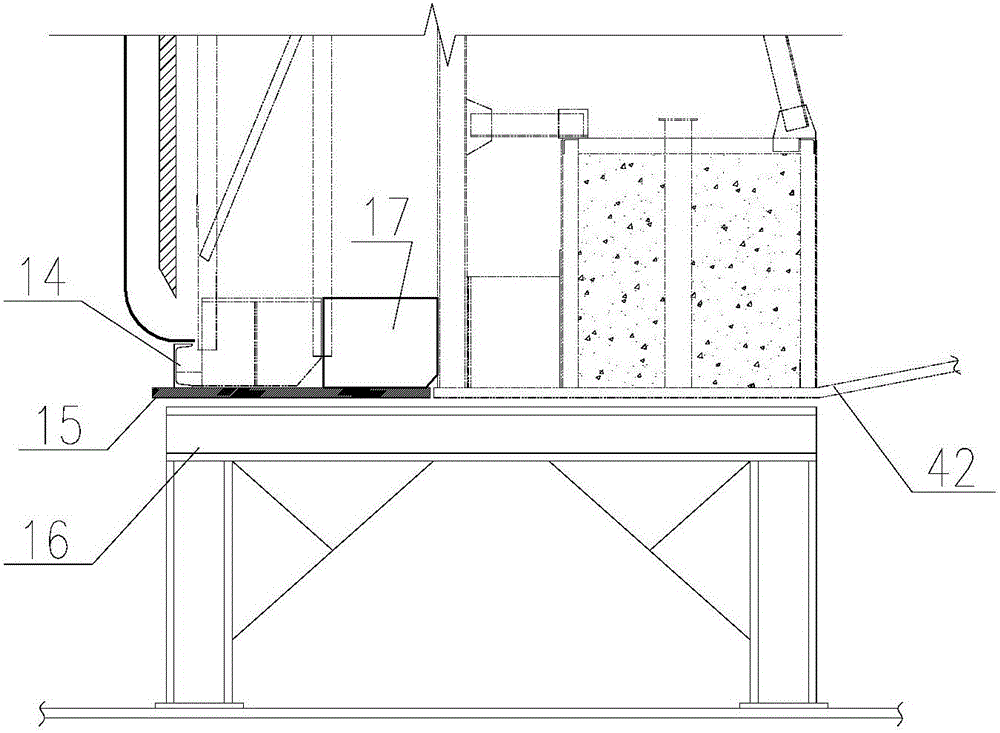

[0046] On the basis of the above-mentioned embodiment, as Figure 4~6 As shown, the operation of lifting the T baffle 5 in the step 2 is as follows: Weld a corbel 12 on each column above the gas cabinet T baffle 5, and the corbel 12 is made of two or more steel plates 121 and a pin shaft 122, the hanging point 13 is welded on the top of the longitudinal support of the T baffle plate 5, and the anchor plate is composed of two or more steel plates 131 and a pin shaft 132; each of the corbels Electric hoist or manual hoist 11 is installed at 12 places, and electric hoist or manual hoist 11 is suspended on the pin shaft of described corbel 12, and the hook of electric hoist or manual hoist 11 is connected with anchor plate.

[0047] This embodiment adopts the method of setting corbels 12 on the columns of the cabinet to lift the T baffle 5 without using large-scale hoisting equipment. In addition, multi-point hoisting is used to adjust the height of different points, which is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com