Soft-rock large-span tunnel double-layer overlapped lining support removing method and structure

A tunnel, double-layer technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of low construction efficiency, difficult construction organization, unfavorable permanent lining stress and waterproof quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

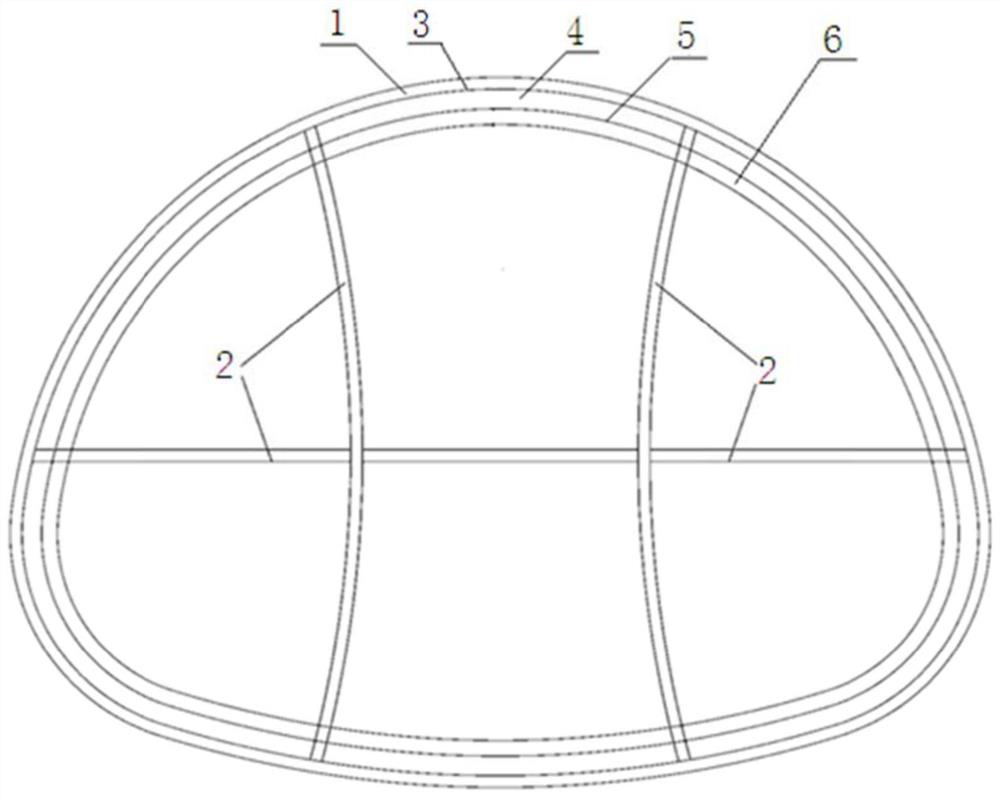

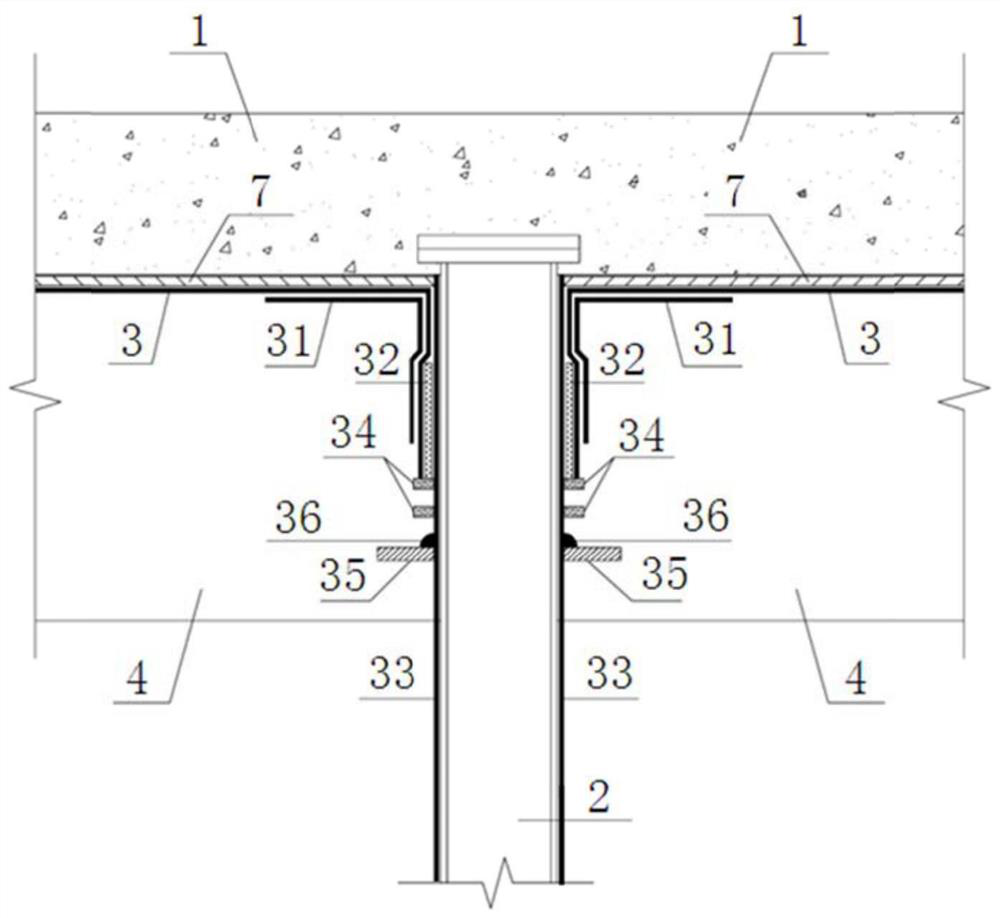

[0042]This embodiment provides a method for removing and bracing the double-layer laminated lining of a soft rock long-span tunnel, such as figure 1 , figure 2 As shown, the method includes the following steps:

[0043] Step S1, leveling the base surface of primary support 1, grouting the back to block water to the waterproof acceptance standard, mechanically breaking the reinforcement mesh of the middle partition wall, spraying wet sprayed concrete, and removing part of the steel support.

[0044] Step S2, removing the foreign matter such as attachments, dirt, rust, etc. on the surface of the temporarily retained shaped steel support 2; laying a geotextile buffer layer 7 and a waterproof layer 3 in sequence close to the base surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com