Foam light refractory casting material and preparation method thereof

A refractory castable, lightweight foam technology, applied in the field of refractory materials, can solve the problems of high production cost, high energy consumption, difficult refractory lining, etc., and achieve the effects of low cost, low thermal conductivity and less heat storage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Determine the requirements for the use of materials: it is planned to be a lightweight refractory castable for foam insulation, with a bulk density of 600Kg / m 3 , use temperature 1100 ℃, compressive strength ≥ 1.5MPa.

[0035] 2. Determine the mixing volume of the mixer and the total weight of the material: the mixing volume is 0.15m 3 , material weight 0.15m 3 ×600Kg / m 3 =90Kg.

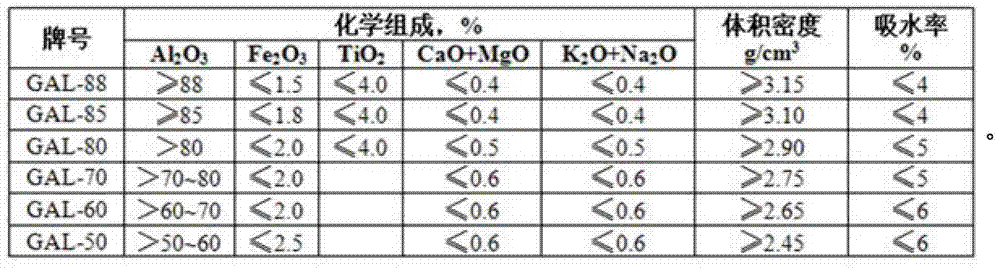

[0036] 3. Select materials and determine the proportion of ingredients:

[0037] A, GAL-50 brand high alumina bauxite powder 63Kg;

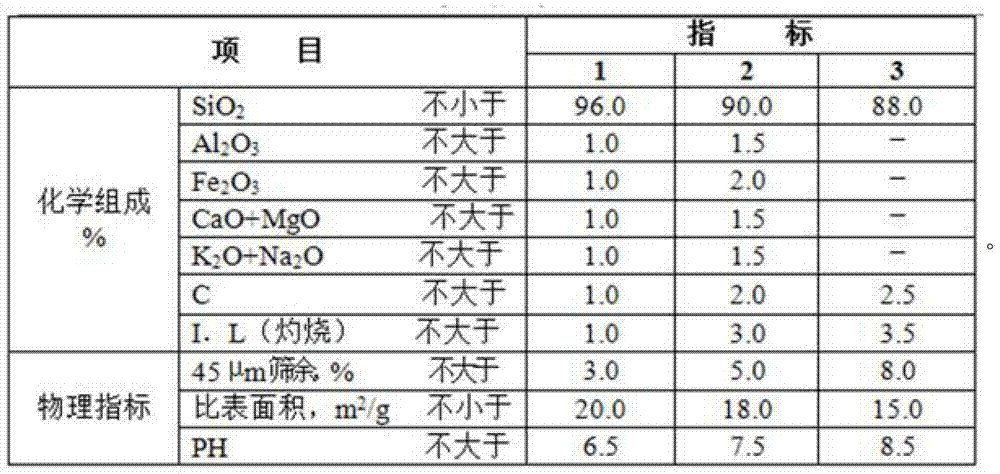

[0038] B. 90 grade silica powder 18Kg;

[0039] C, CA-50 refractory cement is 9Kg;

[0040] D. Sodium tripolyphosphate 0.5Kg (additional);

[0041] E. Calcium oxide powder 1Kg (additional).

[0042] F, 0.3 parts by weight of vegetable protein foaming agent, diluted with water at a ratio of 1:40.

[0043] 4. Weighing: Weigh according to the ingredient list.

[0044] 5. Prepare the foaming machine and vegetable protein foaming agent (diluted with water...

Embodiment 2

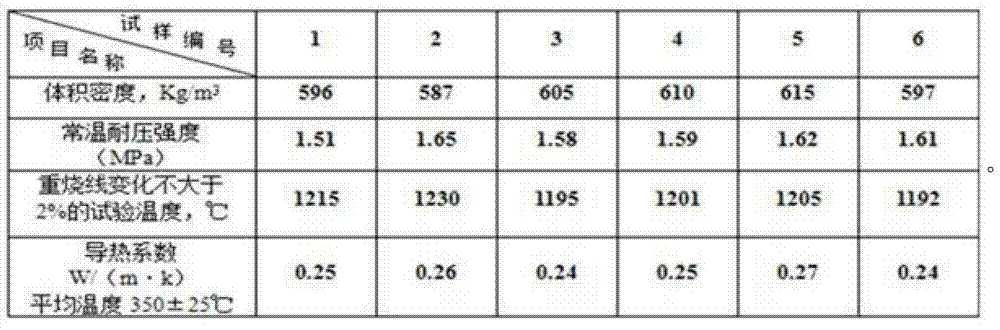

[0052] Performance test of heat insulation layer foam lightweight refractory castable product of the present invention (bulk density 600Kg / m 3 , operating temperature 1100°C, compressive strength ≥ 1.5MPa):

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com