Aerated concrete block and its production process

A technology for air-entrained concrete and concrete blocks, which is applied in the direction of climate sustainability, other household appliances, sustainable waste treatment, etc., to achieve the effects of improving product strength and thermal insulation, reducing cement consumption, and improving dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

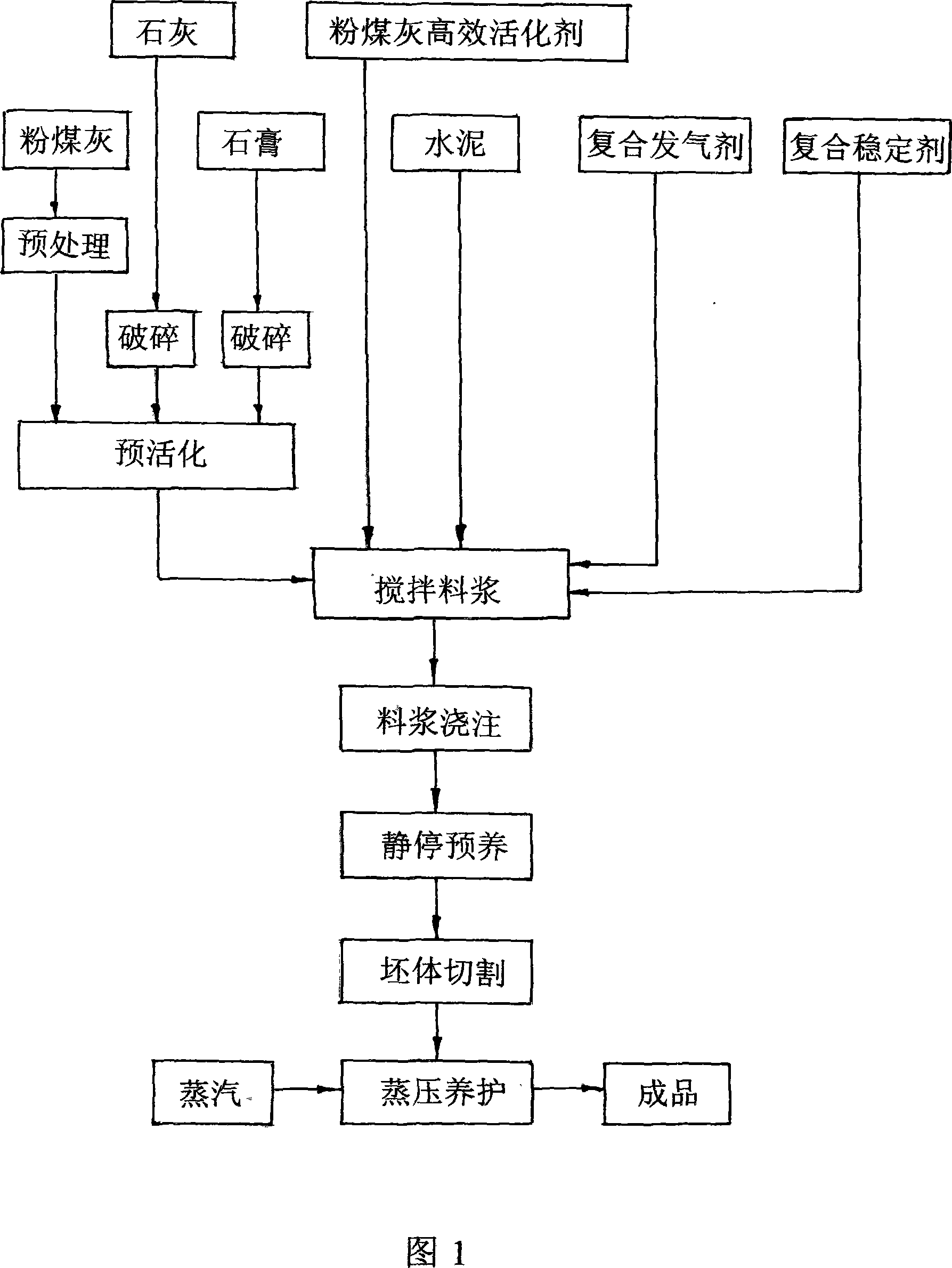

[0029] As shown in Figure 1, it is a process flow chart of the production method of the present invention. The raw material formula of an embodiment of this air-entrained concrete block and parts by weight thereof are:

[0030] 60kg of fly ash, 20kg of lime, 8kg of gypsum, 12kg of cement, 6kg of composite air-generating agent, 1.5kg of high-efficiency fly ash activator, 2.5kg of composite stabilizer and appropriate amount of water.

[0031] 2. The production method of aerated concrete block according to claim 1, characterized in that: the process flow of the production method is:

[0032] (1) Fly ash pretreatment is to dehydrate and concentrate fly ash with a moisture content greater than 30%. The slurry storage tank is used for natural sedimentation and dehydration, or a vacuum dehydrator is used for dehydration, and the fineness requirement is 0.045. mm square hole sieve balance is not more than 30%, and weigh 60kg;

[0033] (2) For the crushing of lime and gypsum, use a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com