A two-component abnormity hollow high moisture absorption curling composite fiber and a preparation method thereof

A composite fiber and high moisture absorption technology, which is applied in the field of polyester composite fibers, can solve the problems of polyester restricting the development of applications, wearing heavy and stuffy, poor moisture absorption and air permeability, etc., to improve application performance, good wearing comfort, good moisture absorption and perspiration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A two-component special-shaped hollow high-moisture-absorbing crimped composite fiber is made by using polyester and bio-based polyamide 56 with a mass ratio of 50:50 and adding adhesives through "8"-shaped spinneret holes. The dry heat shrinkage rate of the polyester is 5%, and the boiling water shrinkage rate is 7%. The dry heat shrinkage rate of the bio-based nylon 56 is 6%, and the boiling water shrinkage rate is 8%. The hollowness of the composite fiber is 20%. The added amount of the binder is 6% of the total mass of the composite fiber.

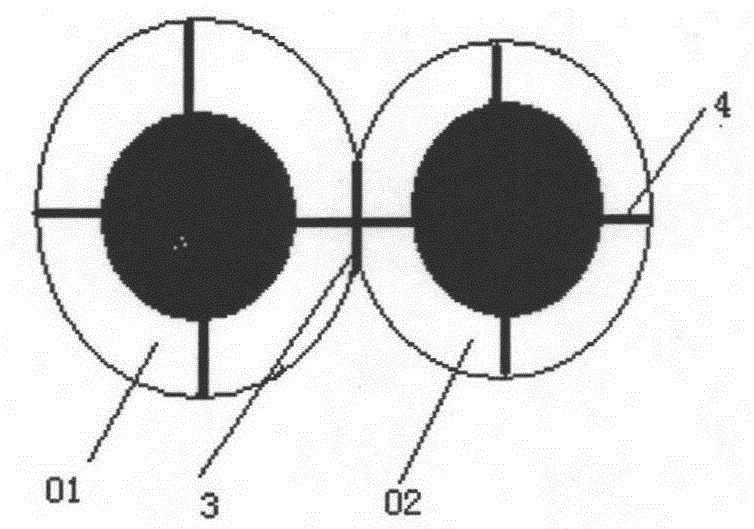

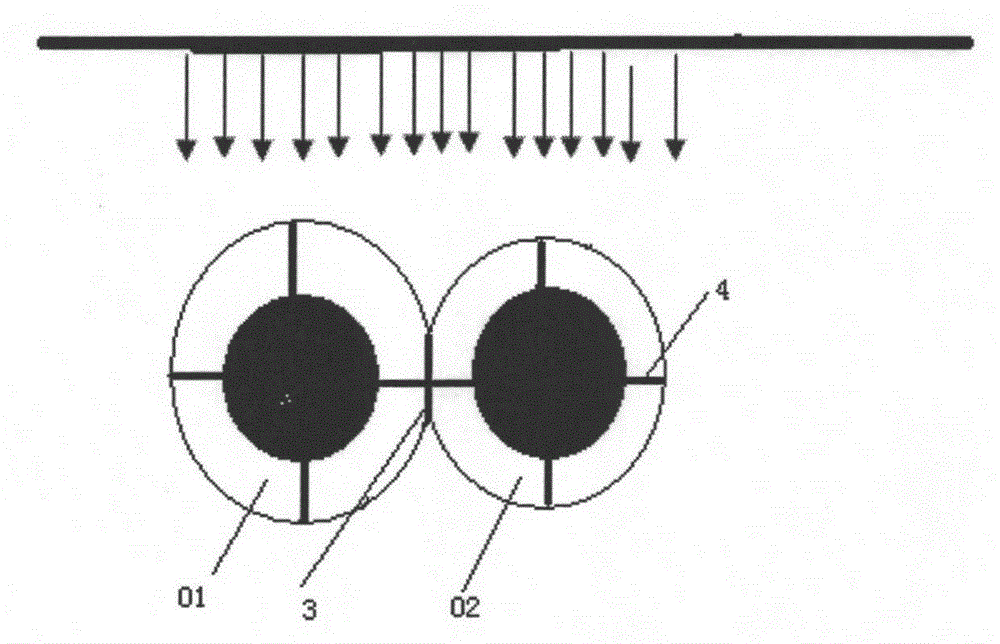

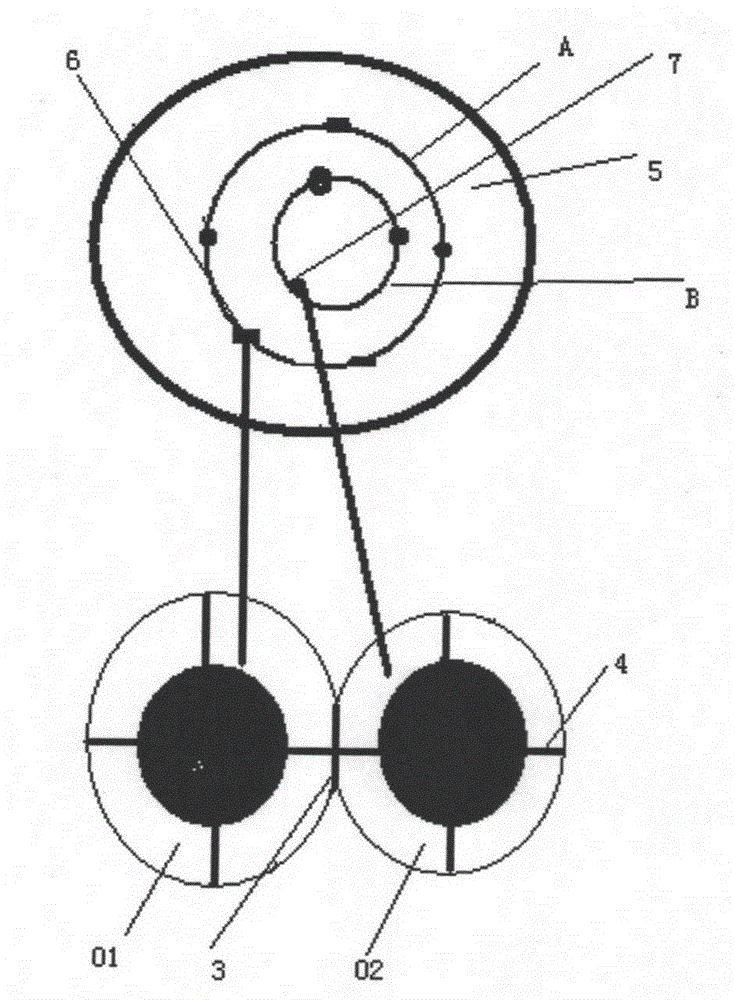

[0034] Such as figure 1 As shown, the "8"-shaped spinneret hole is composed of the first "O"-shaped structure spinneret 01 and the second "O"-shaped structure spinneret 02, the first spinneret 01 and the second spinneret Holes 02 are arranged side by side to form an "8"-shaped structure. The first "O"-shaped structure spinneret 01 and the second "O"-shaped structure spinneret 02 are fixedly connected, and the first "O"-shape...

Embodiment 2

[0039] A two-component special-shaped hollow high-moisture-absorbing curly composite fiber, which is a modified polyamide with a mass ratio of 80:20 of polyester and bio-based polyamide 56, which is a group that can react with both polyester and polyamide, and an adhesive is added. Made through "8"-shaped spinneret holes. The dry heat shrinkage rate of the polyester is 7%, and the boiling water shrinkage rate is 9%. The dry heat shrinkage rate of the bio-based nylon 56 is 12%, and the boiling water shrinkage rate is 20%. The hollowness of the composite fiber is 25%. The added amount of the binder is 10% of the total mass of the composite fiber.

[0040] Such as figure 1 As shown, the "8"-shaped spinneret hole is composed of the first "O"-shaped structure spinneret 01 and the second "O"-shaped structure spinneret 02, the first spinneret 01 and the second spinneret Holes 02 are arranged side by side to form an "8"-shaped structure. The first "O"-shaped structure spinneret 0...

Embodiment 3

[0044] A two-component special-shaped hollow high-moisture-absorbing crimped composite fiber is prepared by using polyester and bio-based polyamide 56 with a mass ratio of 70:30 and adding adhesives through "8"-shaped spinneret holes. The dry heat shrinkage rate of the polyester is 8%, and the boiling water shrinkage rate is 11%. The dry heat shrinkage rate of the bio-based nylon 56 is 18%, and the boiling water shrinkage rate is 30%. The hollowness of the composite fiber is 22%. The added amount of the binder is 7% of the total mass of the composite fiber.

[0045] Such as figure 1 As shown, the "8"-shaped spinneret hole is composed of the first "O"-shaped structure spinneret 01 and the second "O"-shaped structure spinneret 02, the first spinneret 01 and the second spinneret Holes 02 are arranged side by side to form an "8"-shaped structure. The first "O"-shaped structure spinneret 01 and the second "O"-shaped structure spinneret 02 are fixedly connected, and the first "O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com