Preparation method of graphene reinforced metal-matrix composite

A composite material and metal composite technology, which is applied in the field of composite materials, can solve problems such as low efficiency, inapplicability, and complicated extrusion and weaving processes, and achieve the effects of enhanced electrical and thermal conductivity, improved affinity, and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

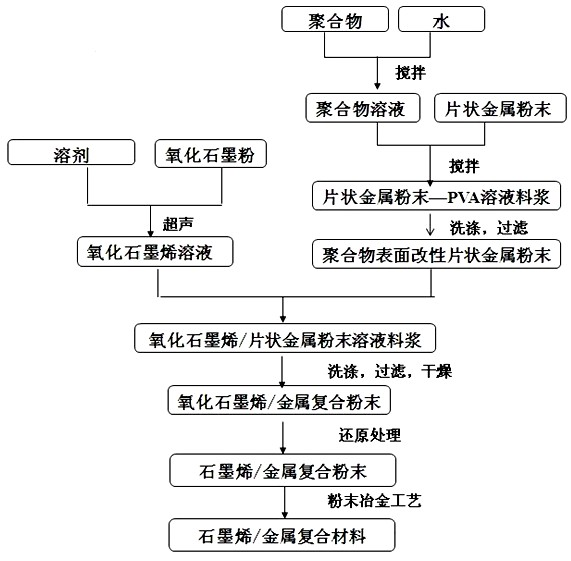

Method used

Image

Examples

Embodiment 1

[0030] Add graphene oxide into deionized water, ultrasonically disperse for 2 hours to uniformly disperse graphene oxide, then add deionized water to adjust the concentration of graphene oxide to obtain a 1.0 mg / mL graphene oxide ethanol solution;

[0031]Under the condition of heating in a constant temperature water bath at 98°C, dissolve polyvinyl alcohol in deionized water, mechanically stir until completely dissolved, add deionized water after cooling to room temperature to adjust the concentration of polyvinyl alcohol, and obtain a 3wt% polyvinyl alcohol aqueous solution;

[0032] Take 100g of aluminum powder and weigh 1g of stearic acid, and add them together into a stirring ball mill for dry grinding for 1 hour to obtain flake aluminum powder with a thickness of 2 μm, and put it into a box furnace at 400°C for pyrolysis. Stearic acid is removed to obtain the desired flake aluminum powder. Since metal aluminum is very active and easily reacts with various substances, a c...

Embodiment 2

[0046] Add graphene oxide into ethanol and add a small amount of chitosan, ultrasonically disperse for 2 hours to disperse graphene oxide evenly, then add ethanol to adjust the graphene concentration to obtain a 2.0mg / mL graphene oxide ethanol solution;

[0047] Dissolving polyvinylpyrrolidone in ethanol and adding a small amount of hydrazine hydrate to it, mechanically stirring until completely dissolved, cooling to room temperature, adding ethanol to adjust the concentration of polyvinylpyrrolidone to obtain a 5wt% polyvinylpyrrolidone ethanol solution;

[0048] Take 100g of 6061 aluminum alloy powder, add 1g of stearic acid, add it to a stirring ball mill and dry grind it to a flake-shaped 6061 aluminum alloy flake powder with a thickness of 1 μm, and put it in argon gas in a box-type resistance furnace at 400°C. Pyrolysis in the atmosphere removes stearic acid;

[0049] Add it to 1L of 5wt% polyvinylpyrrolidone ethanol solution, stir magnetically for 0.5 hours, then wash a...

Embodiment 3

[0053] Add graphene oxide into deionized water and add a small amount of sodium lauryl sulfate, ultrasonically disperse for 2 hours to disperse graphene evenly, then add deionized water to adjust the concentration of graphene oxide to obtain a 5.0mg / mL graphene oxide aqueous solution ;

[0054] Under the condition of heating in a constant temperature water bath at 98°C, dissolve polyvinyl alcohol in deionized water and add a small amount of ethylenediamine to it, stir mechanically until it is completely dissolved, and then add deionized water to adjust the concentration of polyvinyl alcohol after cooling to room temperature to obtain 0.2 wt% polyvinyl alcohol aqueous solution;

[0055] Take 200g of copper powder, add 200mL of pure water, and add it to a planetary ball mill for wet grinding to obtain a slurry of flaky copper powder with a thickness of 500nm, then perform suction filtration and drying to obtain a copper powder with a thickness of 500nm;

[0056] Take 100g of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com