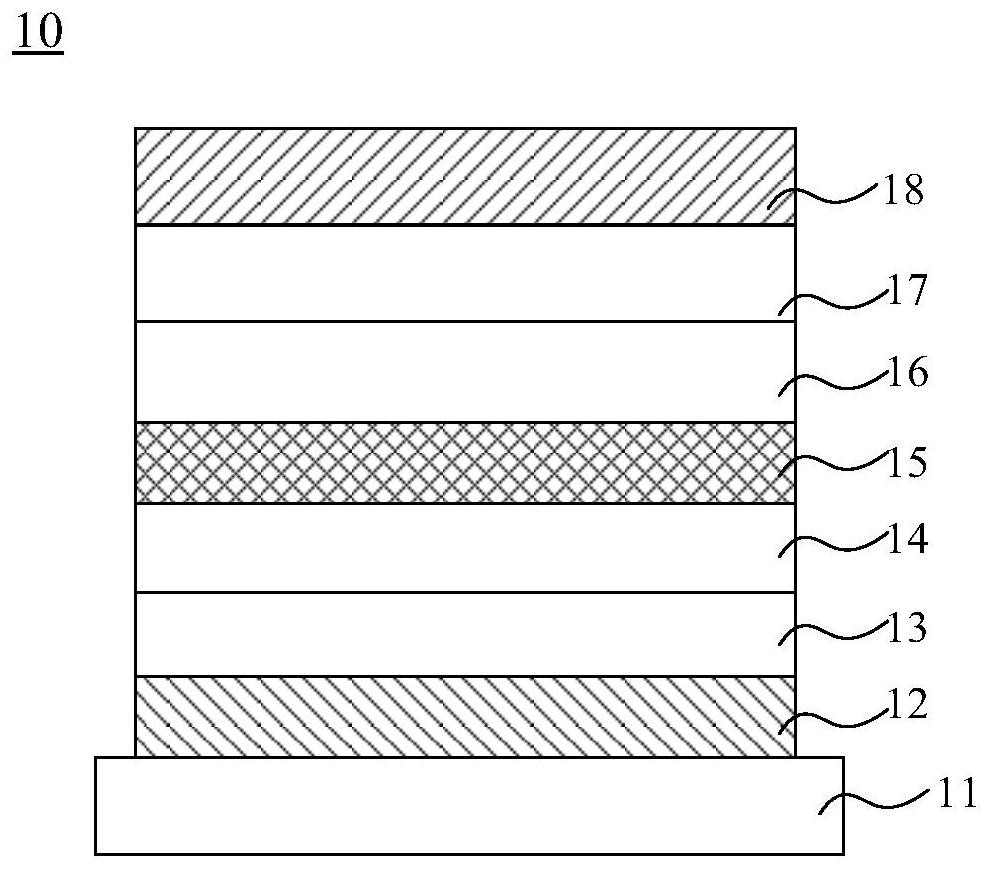

Organic compound, display panel and display device

An organic compound and bonding technology, applied in silicon organic compounds, isotope introduction of organic compounds, organic chemistry, etc., can solve the problems of low cost, high luminous efficiency, and long service life, and achieve low cost, high current efficiency, and long life. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

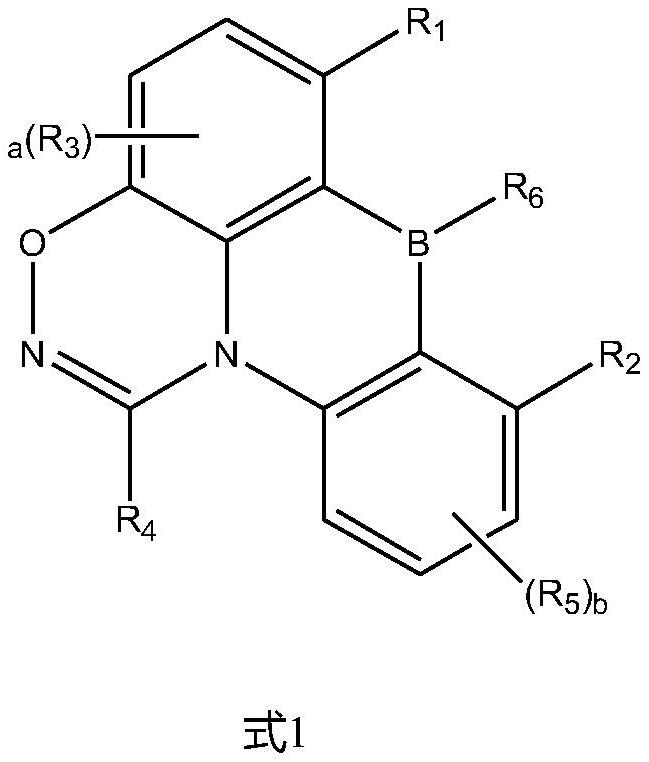

[0116] Preparation of organic compounds 1

[0117] Raw material A (5.52 g, 40 mmol), raw material B (11.2 g, 50 mmol) and 5 g of Na 2 CO 3 Put it into a three-necked flask, add 80 ml of chloroform solvent to dissolve the above compound, stir and heat up to 80° C. to condense and reflux, and keep for 12 hours. After cooling to room temperature, 100 ml of n-hexane was added, and the mixture was stirred uniformly. The mixture was filtered to obtain a solid, which was continuously washed with acetone to obtain 13.4 g of Intermediate 1 in total.

[0118] To a 400 ml flask containing intermediate 1 (1.06 g, 3 mmol) and o-dichlorotoluene under nitrogen atmosphere was added boron tribromide (1.3 ml, 12 mmol) reagent. After completion of the dropwise addition, the temperature was raised to 160° C., stirred for 24 hours, and cooled to room temperature. Add N,N-diisopropylethylamine (22 ml, 3.35 mmol) and stir until exothermic. The solvent was then distilled off under reduced pressu...

Embodiment 2

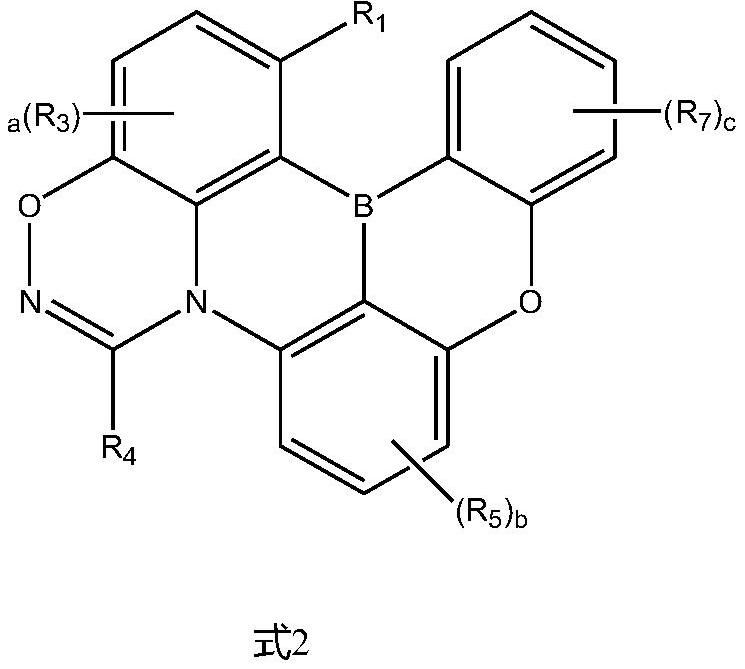

[0121] Preparation of organic compounds 93

[0122] Raw material C 20 mmol, raw material D 50 mmol, raw material E 20 mmol and 5 g Na 2 CO 3 Put it into a three-necked flask, add 80 ml of chloroform solvent to dissolve the above compound, stir and heat up to 80° C. to condense and reflux, and keep for 12 hours. After cooling to room temperature, 100 ml of n-hexane was added, and the mixture was stirred uniformly. The mixture was filtered to give a solid which was washed continuously with acetone to give 10 mmol of Intermediate 2 in total.

[0123] To a 400 ml flask containing 3 mmol of intermediate 2 and o-dichlorotoluene was added 1.3 ml (12 mmol) of boron tribromide reagent under nitrogen atmosphere. After completion of the dropwise addition, the temperature was raised to 160° C., stirred for 24 hours, and cooled to room temperature. After completion of the dropwise addition, the temperature was raised to 160° C., stirred for 24 hours, and cooled to room temperature. Ad...

Embodiment 3

[0127] Preparation of organic compounds 101

[0128] 40 mmol of raw material F, 50 mmol of raw material G and 5 g of Na 2 CO 3 Put it into a three-necked flask, add 80 ml of chloroform solvent to dissolve the above compound, stir and heat up to 80° C. to condense and reflux, and keep for 12 hours. After cooling to room temperature, 100 ml of n-hexane was added, and the mixture was stirred uniformly. The mixture was filtered to give a solid which was washed continuously with acetone to give 32 mmol of Intermediate 4 in total.

[0129] To a 400 ml flask containing 3 mmol of intermediate 4 and o-dichlorotoluene was added 1.3 ml (12 mmol) of boron tribromide reagent under nitrogen atmosphere. After completion of the dropwise addition, the temperature was raised to 160° C., stirred for 24 hours, and cooled to room temperature. After completion of the dropwise addition, the temperature was raised to 160° C., stirred for 24 hours, and cooled to room temperature. Add N,N-diisopro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com