Embedded photoelectrode based on low-temperature liquid metal integration and large-scale preparation method

A low-temperature liquid and liquid metal technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of large limitations of integration methods, complex processes, high costs, etc., and achieve strong resistance to external forces, simple process, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

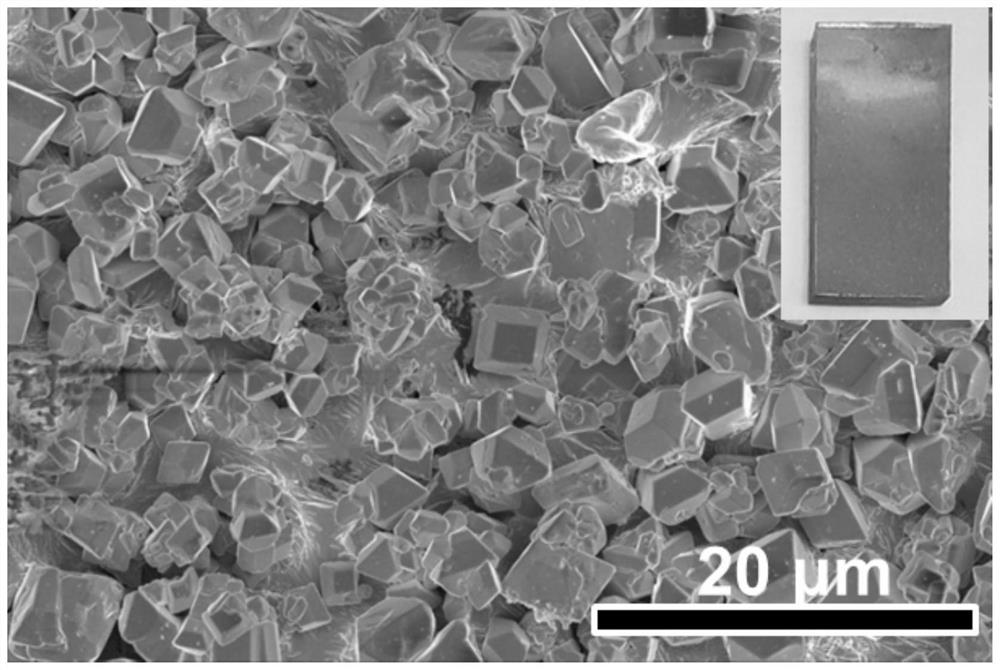

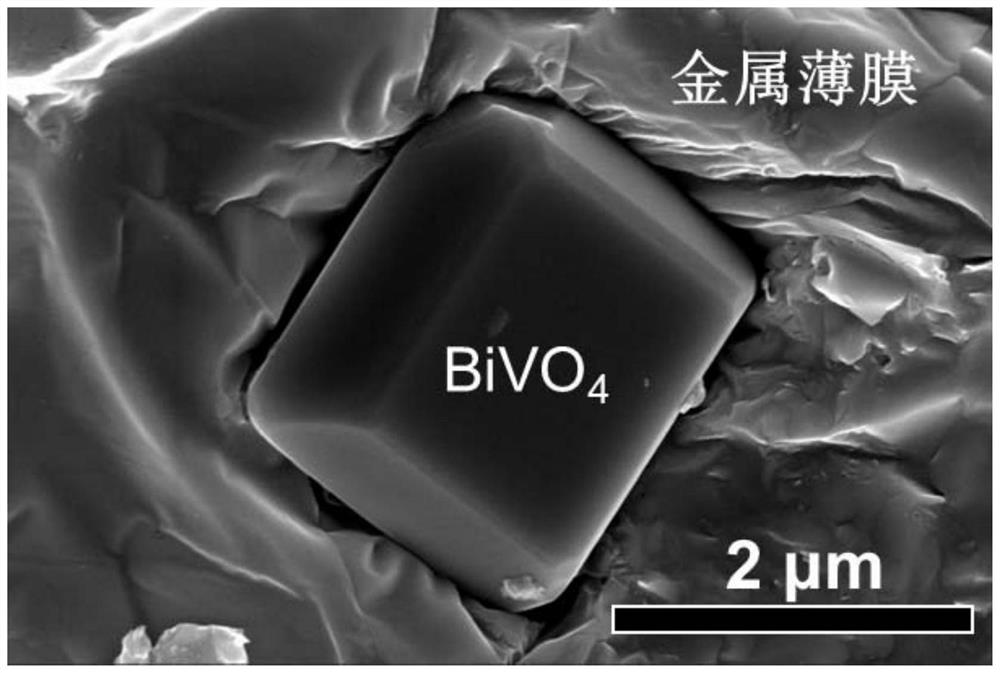

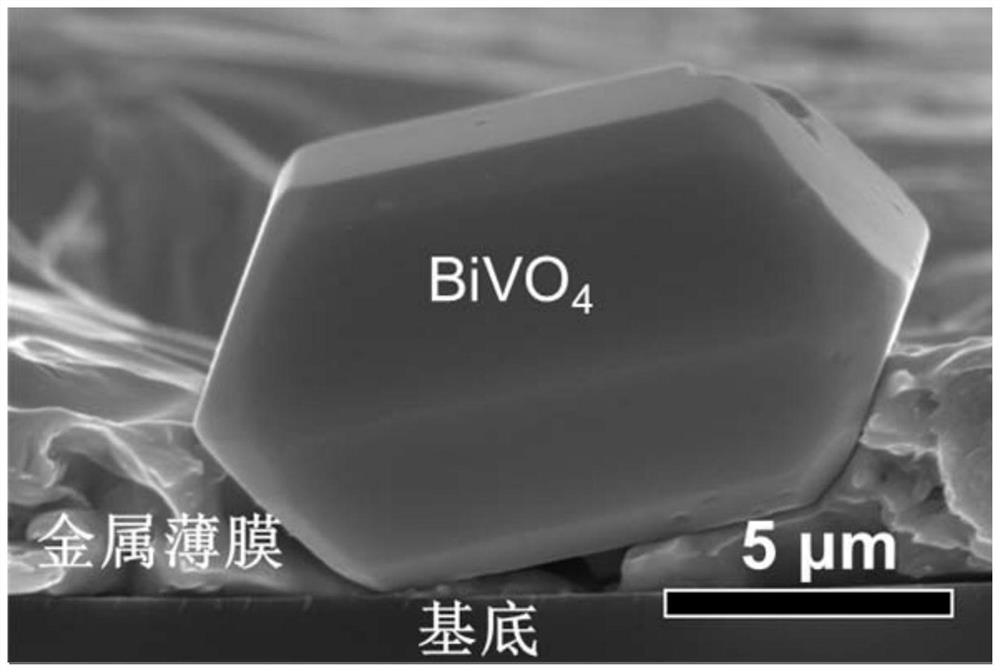

[0045] In the specific implementation process, the present invention provides an embedded photoelectrode based on low-temperature liquid metal integration and a large-scale preparation method. Taking advantage of the low melting point, easy processing and high electrical conductivity of low-temperature liquid metals, the low-temperature Field metal is first heated above the melting point and transformed into a liquid state. In the molten state of the Field metal, it is scraped on the substrate to form a film, and then the semiconductor photoelectric Catalyst particles are ultrasonically dispersed in isopropanol solution, and uniformly drop-coated on the surface of the Field metal film to form a film, and then pressure is applied by means of rolling to embed the semiconductor photocatalyst particles in the liquid Field metal film. After cooling and solidifying, use an air gun to blow Scanning (or ultrasound) removes the semiconductor photocatalyst particles that are not embedded...

Embodiment 1

[0057] In this embodiment, liquid metal and BiVO are used on the quartz substrate 4 Powder preparation of BiVO 4 Photoelectrode, comprising the steps of:

[0058] Take 30mg of BiVO 4 The powder was added to 30ml of isopropanol solution, and ultrasonically dispersed for 30min to obtain a suspension. The suspension was filtered and dried for later use. Quartz slices with a surface size of 1cm×3cm were ultrasonically cleaned with ethanol, acetone, and isopropanol for 15 minutes, then blown dry with a nitrogen gun, heated the above-mentioned quartz slices to 108°C on a heating table, and then scraped a uniform layer on the quartz slices with a scraper. Field metal film. Cover the powder film obtained by the above-mentioned suction filtration on the metal film, and use a silica gel roller to roll it horizontally and vertically for 3 to 5 times respectively. After the metal is cooled, use a nitrogen gun to remove excess powder particles on the surface, and place it on a heating...

Embodiment 2

[0061] In this example, liquid metal and commercial ZnO powder are used to prepare corresponding photoelectrodes on a quartz substrate, and the universality of the present invention for different photocatalyst particles is verified:

[0062] 30 mg of commercial ZnO powder was added to 30 ml of isopropanol solution, and ultrasonically dispersed for 30 min to obtain a suspension. The suspension was filtered by suction and dried for later use. Quartz slices with a surface size of 1cm×3cm were ultrasonically cleaned by ethanol, acetone, and isopropanol for 15 minutes, then blown dry with a nitrogen gun, heated the quartz slices to 108°C on a heating platform, and then scraped a uniform layer on the quartz slices with a scraper. Field metal film. Cover the ZnO powder thin film obtained by the suction filtration above on the metal film, and use a silica gel roller to roll it horizontally and vertically for 3 to 5 times respectively. After the metal is cooled, use a nitrogen gun to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com