Solid sodium ion conductor material and preparation method thereof

A sodium ion conductor and solid-state technology, which is applied in the field of solid sodium ion conductor materials and its preparation, can solve the problems of battery short circuit, low conductivity, and increased cost, and achieve the effects of solving liquid leakage, high ion conductivity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

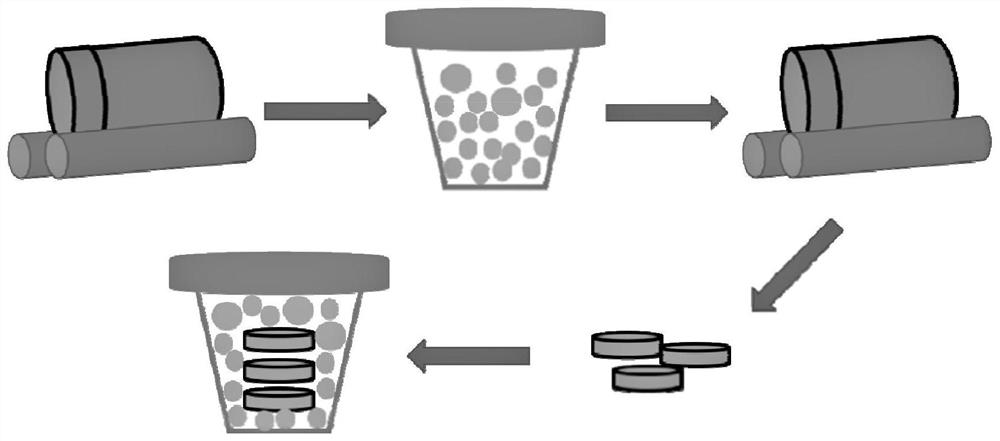

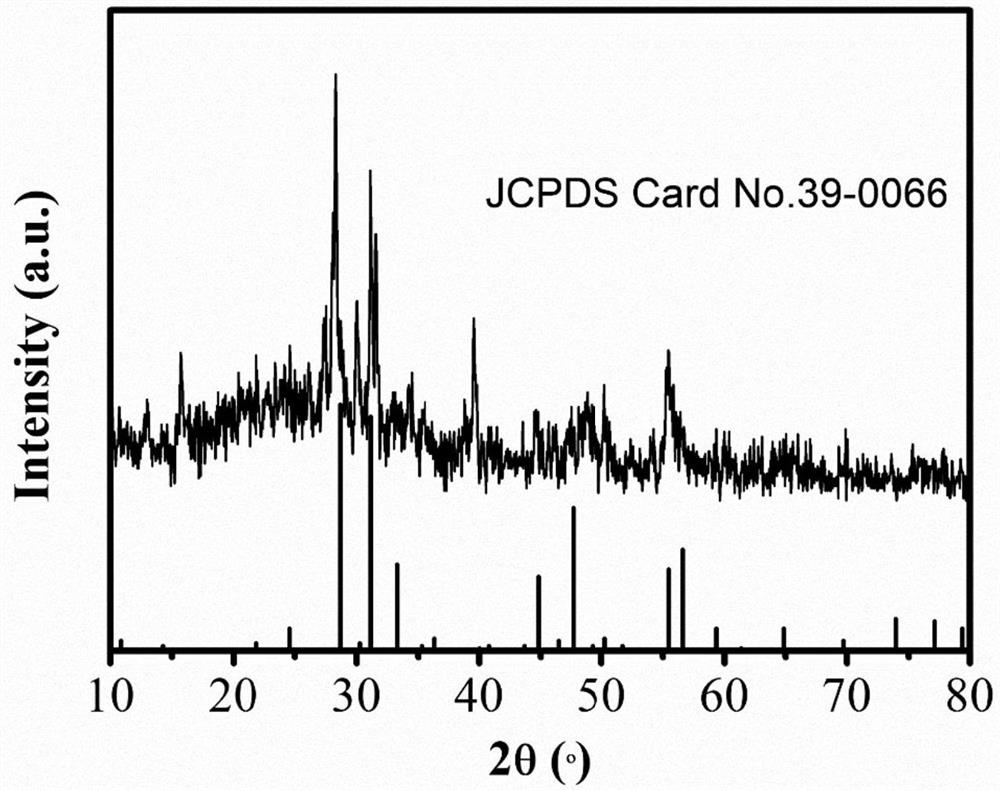

[0024] In the present embodiment, solid sodium ion conductor material chemical structure general formula Na 3x La 2 / 3-x ZrO 3 The value of x in the middle is 0.075, and the corresponding chemical structure is Na 0.225 La 0.592 ZrO 3 . The preparation method of solid sodium ion conductor material refers to figure 1 , the specific method is as follows:

[0025] Weigh 0.1193g of sodium carbonate, 0.9650g of lanthanum oxide and 1.2322g of zirconia and mix them, add 40ml of isopropanol, and ball mill in a ball mill at a revolution speed of 300rpm for 24h. The slurry obtained from the ball mill was suction-filtered and dried at 60° C. for 2 hours to obtain a white powder. Put the obtained white powder into a box-type resistance furnace and heat at 3°C min -1 The heating rate is increased to 900°C for calcination, kept for 10 hours, and cooled to room temperature with the furnace. Add 40ml of isopropanol to the calcined powder, ball mill for 24 hours at a revolution speed ...

Embodiment 2

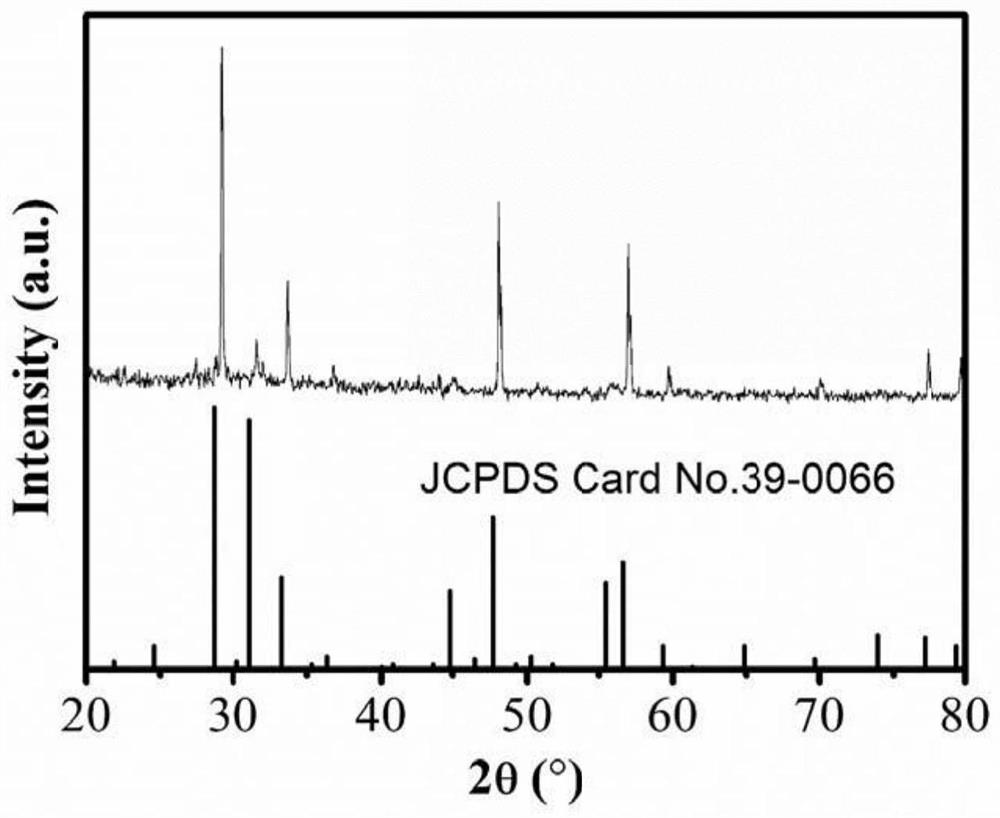

[0031] In the present embodiment, solid sodium ion conductor material chemical structure general formula Na 3x La 2 / 3-x ZrO 3 The value of x in the middle is 0.16, and the corresponding chemical structure is Na 0.48 La 0.5 ZrO 3 . The preparation method of solid sodium ion conductor material is as follows:

[0032] Weigh 0.2544g of sodium carbonate, 0.8145g of lanthanum oxide and 1.2322g of zirconia and mix them, add 40ml of isopropanol, and ball mill in a ball mill at a revolution speed of 300rpm for 24h. The slurry obtained from the ball mill was suction-filtered and dried at 60° C. for 2 hours to obtain a white powder. Put the obtained white powder into a box-type resistance furnace and heat at 3°C min -1 The heating rate is increased to 900°C for calcination, kept for 10 hours, and cooled to room temperature with the furnace. Add 40ml of isopropanol to the calcined powder, and ball mill for 24 hours at a revolution speed of 300rpm. Suction-filter the slurry obta...

Embodiment 3

[0034]In the present embodiment, solid sodium ion conductor material chemical structure general formula Na 3x La 2 / 3-x ZrO 3 The value of x in the middle is 0.04, and the corresponding chemical structure is Na 0.12 La 0.62 ZrO 3 . The preparation method of solid sodium ion conductor material is as follows:

[0035] Weigh 0.0636g of sodium carbonate, 1.0106g of lanthanum oxide and 1.2322g of zirconia and mix them, add 40ml of isopropanol, and ball mill in a ball mill at a speed of 300rpm for 48h. The slurry obtained from the ball mill was suction-filtered and dried at 60° C. for 2 hours to obtain a white powder. Put the obtained white powder into a box-type resistance furnace and heat at 3°C min -1 The heating rate is increased to 800 ° C for calcination, kept for 12 hours, and cooled to room temperature with the furnace. Add 40 ml of isopropanol to the calcined powder, and ball mill for 48 hours at a rotation speed of 300 rpm. Suction-filter the slurry obtained by b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com