Nano composite photocatalytic material and method for preparing same

A technology of nano-composite materials and photocatalytic materials, which is applied in the field of nano-composite materials and photocatalysis, can solve the problems of not examining the photocatalytic properties of composite materials, the photocatalytic properties cannot be reflected, and the structure does not have good characteristics, and achieves good industrial applications. Prospects, easy industrial preparation, and the effect of good surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

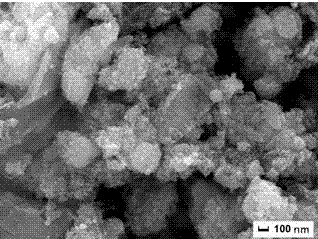

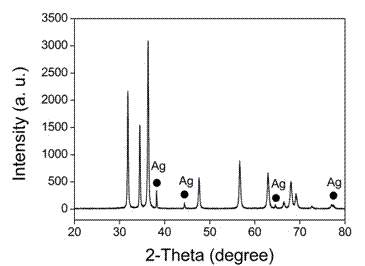

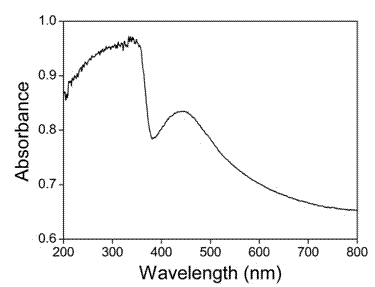

[0023] Dissolve 2.19 g of zinc acetate in 40 mL of deionized water, dissolve 10 mg of silver acetate in 5 mL of deionized water, mix and stir the zinc acetate solution and silver acetate solution for 30 minutes to obtain solution A; prepare 3 mol / L Sodium hydroxide solution, 20 mg graphene oxide in 20 mL deionized water for 3 hours, then added to solution A and stirred for 1 hour, then added sodium hydroxide aqueous solution to adjust the pH of the solution to 9, stirred for 30 minutes, then transferred to volume In a 100 mL reactor liner, use deionized water to adjust the volume of the reaction material in the reactor liner to 75% of the volume of the reactor liner, then place it in a stainless steel jacket, seal it, and keep it warm at 200°C for 10 hours Carry out hydrothermal treatment, then allow the reaction kettle to cool down to room temperature naturally, after unloading the kettle, centrifuge, wash the reaction product repeatedly with absolute ethanol and deionized wat...

Embodiment 2

[0025] Dissolve 2.19 g of zinc acetate in 40 mL of deionized water, dissolve 20 mg of silver acetate in 5 mL of deionized water, mix and stir the zinc acetate solution and silver acetate solution for 30 minutes to obtain solution A; prepare 3 mol / L Sodium hydroxide solution, sonicate 50 mg graphene oxide in 20 mL deionized water for 4 hours, then add it to solution A and stir for 1 hour, then add aqueous sodium hydroxide solution to adjust the pH of the solution to 10, stir for 30 minutes, transfer to volume In a 100 mL reactor liner, use deionized water to adjust the volume of the reaction material in the reactor liner to 75% of the volume of the reactor liner, then place it in a stainless steel jacket, seal it, and keep it warm at 180°C for 12 hours Carry out hydrothermal treatment, then allow the reaction kettle to cool down to room temperature naturally, after unloading the kettle, centrifuge, wash the reaction product repeatedly with absolute ethanol and deionized water, f...

Embodiment 3

[0027] Dissolve 2.19 g of zinc acetate in 40 mL of deionized water, dissolve 40 mg of silver acetate in 5 mL of deionized water, mix and stir the zinc acetate solution and silver acetate solution for 30 minutes to obtain solution A; prepare 3 mol / L Sodium hydroxide solution, 100 mg graphene oxide in 20 mL deionized water for 4 hours, then added to solution A and stirred for 1 hour, then added sodium hydroxide aqueous solution to adjust the pH of the solution to 11, stirred for 30 minutes, then transferred to volume In a 100 mL reactor liner, use deionized water to adjust the volume of the reaction material in the reactor liner to 75% of the volume of the reactor liner, then place it in a stainless steel jacket, seal it, and keep it warm at 160°C for 16 hours Carry out hydrothermal treatment, then allow the reaction kettle to cool down to room temperature naturally, after unloading the kettle, centrifuge, wash the reaction product repeatedly with absolute ethanol and deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com