Preparation method of polycrystalline silicon

A polysilicon preparation and polysilicon technology, applied in chemical instruments and methods, silicon compounds, sustainable manufacturing/processing, etc., can solve the problems of decreasing silicon deposition rate, affecting average deposition rate and reduction power consumption, etc. The effect of reducing the energy consumption of polysilicon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

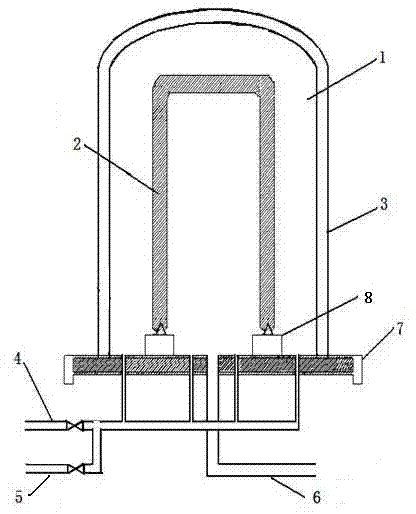

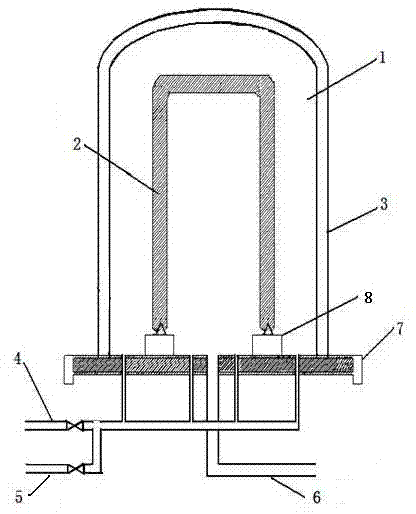

Image

Examples

Embodiment 1

[0039] The polysilicon deposition reaction was carried out in the same steps as Comparative Example 1, while HCl was preheated to 200°C at a certain rate and continuously added to the feed tube so that the ratio of HCl / TCS in the reaction gas was about 5% by mole. . After starting the reaction, keep the surface temperature of the silicon core at 1080-1100°C. After the trichlorosilane and hydrogen are heated to 200°C, they are passed into the reactor. The initial flow rate of the trichlorosilane is 2Nm3 / h, which increases to 42Nm3 / h at a constant speed and remains constant, and the speed-up time is 30h. The initial hydrogen flow rate was 13Nm3 / h, which gradually increased to 189Nm3 / h. During the whole deposition process, the molar ratio of hydrogen to trichlorosilane gradually decreased from 6.5 to 4.5. When the reaction time reaches 40-50 hours, there is no atomization phenomenon in the reactor, and the feed amount, proportion and surface temperature of the silicon rods conti...

Embodiment 2

[0041] The polysilicon deposition reaction was carried out in the same steps as in Comparative Example 1. After starting the reaction, keep the surface temperature of the silicon core at 1080-1100°C. After the trichlorosilane and hydrogen are heated to 200°C, they are passed into the reactor. The initial flow rate of the trichlorosilane is 2Nm3 / h, which increases to 42Nm3 / h at a constant speed and remains constant, and the speed-up time is 30h. The initial hydrogen flow rate was 13Nm3 / h, which gradually increased to 189Nm3 / h. During the whole deposition process, the molar ratio of hydrogen to trichlorosilane gradually decreased from 6.5 to 4.5. When the reaction time reaches 40-50 hours, atomization occurs in the reactor. At this time, continue to keep the feed amount, proportion and surface temperature of the silicon rod unchanged, slowly open the HCl valve, and continuously Add it into the feed pipe so that the ratio of HCl / TCS in the reaction gas is about 10% (mole), react...

Embodiment 3

[0043] The polysilicon deposition reaction is carried out by adopting the method of the present invention. The raw materials trichlorosilane and hydrogen are mixed and heated to 200°C, and then passed into the reactor. The initial flow rate of trichlorosilane is 2Nm3 / h, which increases to 42Nm3 / h at a constant speed and remains constant, and the initial flow rate of hydrogen gas is 13Nm3 / h, which gradually increases To 189Nm3 / h, after reacting at 1100°C for 20h at a high temperature, feed HCl gas (preheated to 200°C) with a flow rate of 2Nm3 / h and 6% trichlorosilane into the reactor. After another 30 hours of reaction, the silicon core grows to a diameter of about 65mm, and HCl gas with a percentage of 18% of trichlorosilane is introduced. After another 30 hours of reaction, the silicon core grows to a diameter of about 100mm, and HCl gas with a percentage of 15% of trichlorosilane is introduced. The reaction was continued for 10 h, and the feed amount of HCl gas was kept con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com