Preparation method of electrodepositing Bi2Te3 mixed with thin-film thermoelectric material

A technology of electrodeposition and thermoelectricity, which is applied in electrolytic inorganic material coating, manufacture/processing of thermoelectric devices, etc., can solve the problems of rough appearance and difficulty in practical application of thin-film thermoelectricity materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

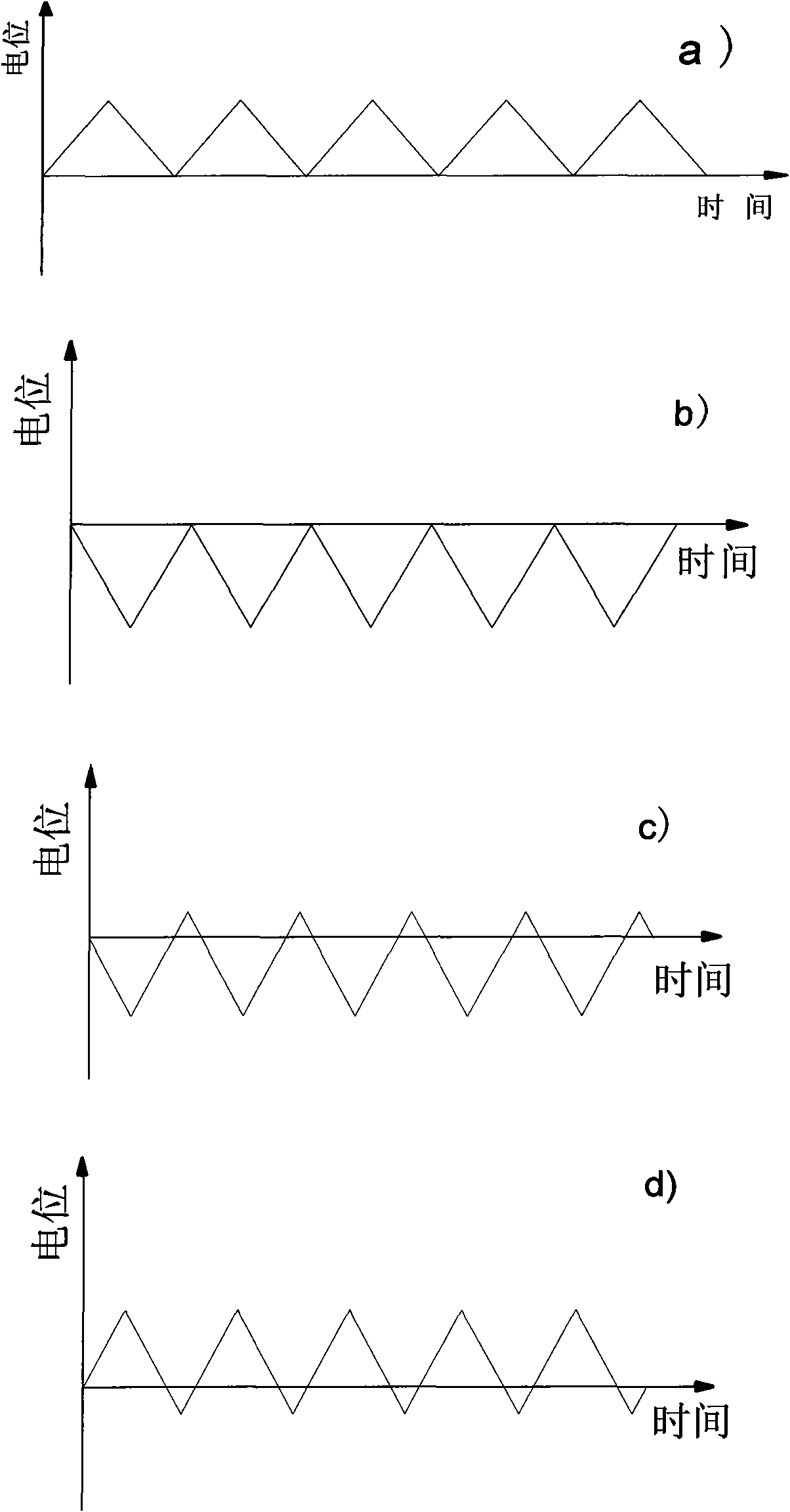

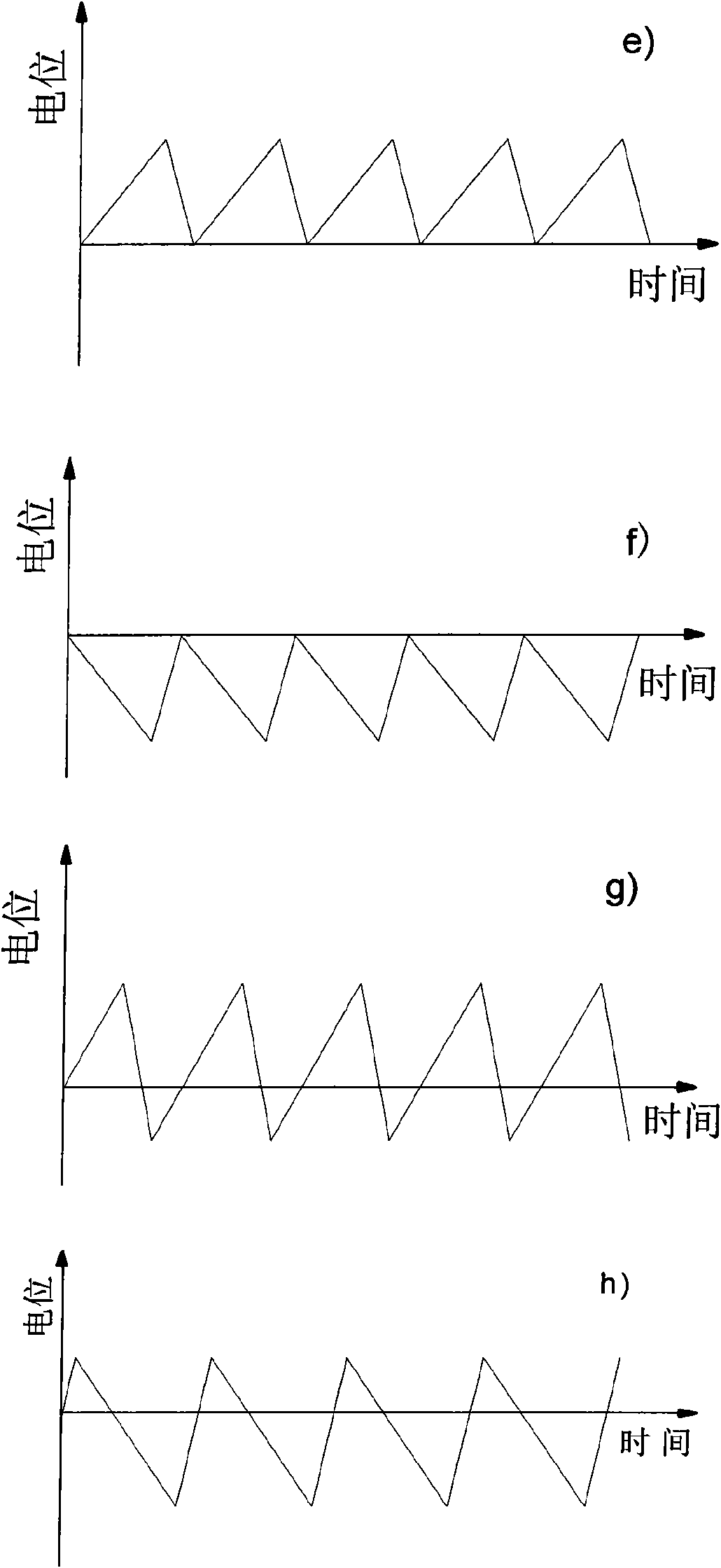

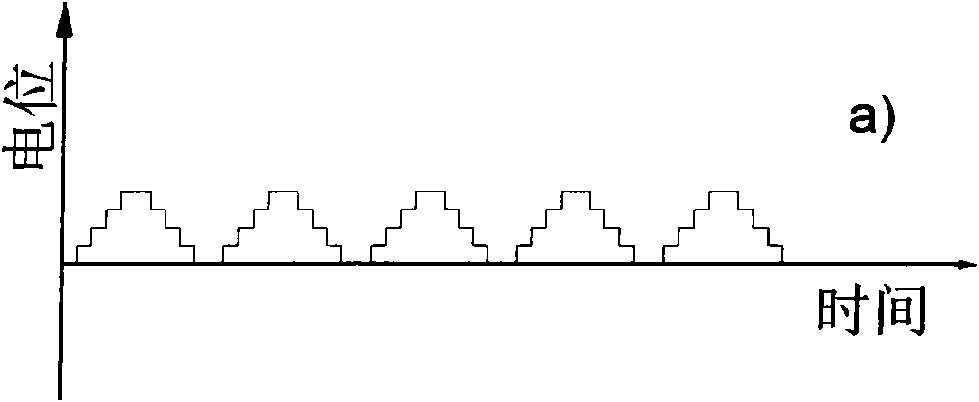

[0024] Example 1: Liquid-phase electrodeposition of P-type Bi-Te-Sb thin film thermoelectric material using continuous forward and reverse symmetric dynamic potential electrodeposition

[0025] Take 10ml of analytically pure nitric acid, add 50ml of distilled water to make nitric acid aqueous solution. Then weigh 10 grams of bismuth nitrate, slowly add it into the prepared nitric acid solution, and stir continuously to dissolve it, then add 4 grams of tellurous acid and stir to dissolve it. Take another 150ml of distilled water, add 10g of tartaric acid, stir to dissolve it, and make a solution. Weigh 8 grams of antimony trioxide, slowly add it into the prepared tartaric acid solution, and stir to dissolve it. Then take 100ml of distilled water, add 10g of potassium chloride, and stir to dissolve it. Then the above solutions were mixed and slowly poured into a 1000ml volumetric flask. Add distilled water to the 1L mark to prepare an electrodeposition solution. Pour the pre...

Embodiment 2

[0028] Example 2: Liquid-phase electrodeposition of P-type Bi-Te-Sb thin film thermoelectric material using continuous forward and reverse symmetric dynamic current electrodeposition

[0029] Take 10ml of analytically pure nitric acid, add 50ml of distilled water to make nitric acid aqueous solution. Then weigh 10 grams of bismuth nitrate, slowly add it into the prepared nitric acid solution, and stir continuously to dissolve it, then add 4 grams of tellurous acid and stir to dissolve it. Take another 150ml of distilled water, add 10g of tartaric acid, stir to dissolve it, and make a solution. Weigh 8 grams of antimony trioxide, slowly add it into the prepared tartaric acid solution, and stir to dissolve it. Then take 100ml of distilled water, add 10g of potassium chloride, and stir to dissolve it. Then the above solutions were mixed and slowly poured into a 1000ml volumetric flask. Add distilled water to the 1L mark to prepare an electrodeposition solution. Pour the prepa...

Embodiment 3

[0031] Example 3: Liquid-phase electrodeposition of N-type Bi-Te-Se thin film thermoelectric material by electrodeposition with continuous positive current flow

[0032] Take 90ml of analytically pure nitric acid, add 500ml of distilled water to make nitric acid aqueous solution. Then weigh 50 grams of bismuth nitrate, slowly add it into the prepared nitric acid solution, and stir continuously to dissolve it, then add 120 grams of tellurous acid and stir to dissolve it. Weigh 10 grams of selenous acid, slowly add it to the prepared solution, and stir to dissolve it. Then weigh 50 g of sodium nitrate and add it to the solution, and stir to dissolve it. Then weigh 80 g of citric acid and add it to the solution, and stir to dissolve it. Then slowly pour the above solution into a 1000ml volumetric flask. Slowly add distilled water to the 1L mark to prepare an electrodeposition solution. Pour the prepared electrodeposition solution into the electrodeposition container.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com