Nickel and cobalt binary anode material precursor preparing method and nickel and cobalt binary anode material precursor prepared through method

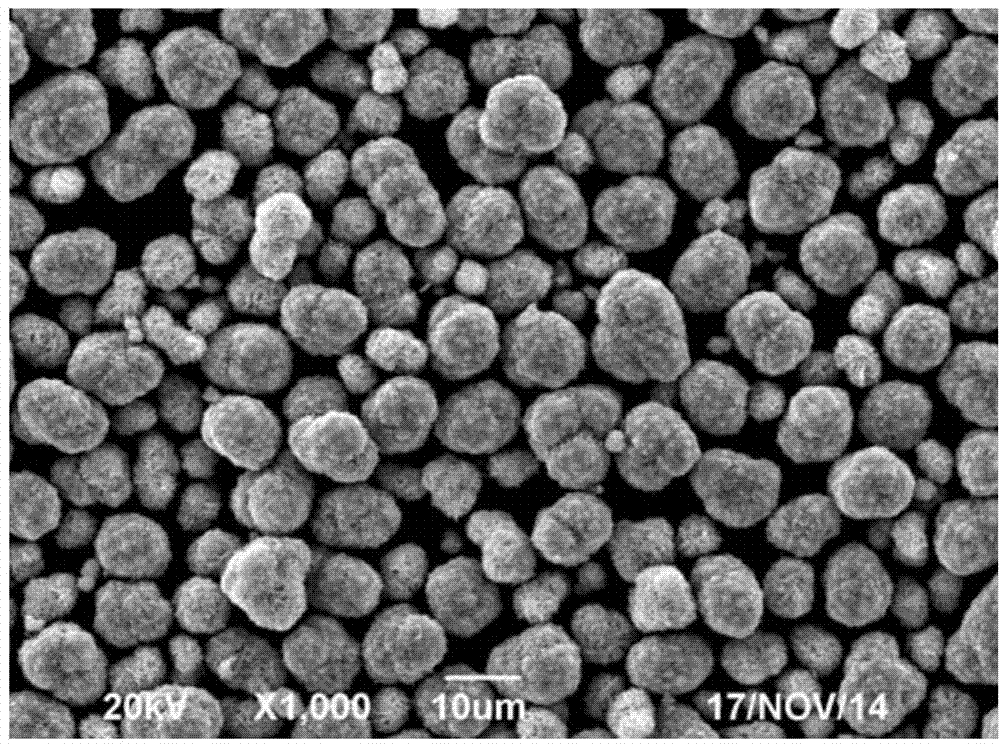

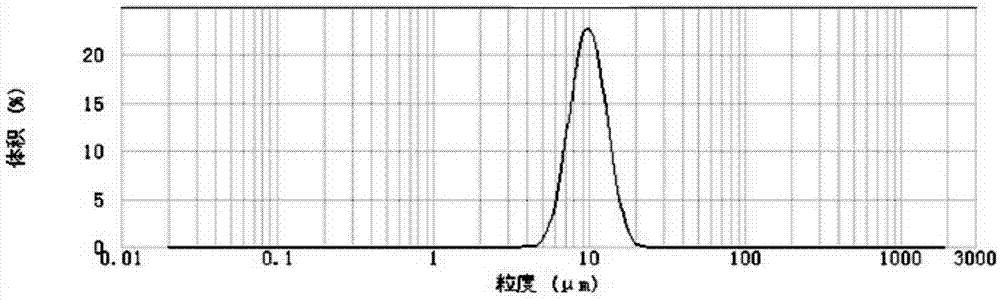

A cathode material and precursor technology, which is applied in the field of nickel-cobalt binary cathode material precursors, can solve the problems of easy aggregation of precursor particles, flake or polygonal shape, uneven distribution of material particle size and shape, and achieve surface morphology Good, high tap density, effect of increasing voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a nickel-cobalt binary cathode material precursor, comprising the following steps:

[0033] Micropowder elimination step: the aqueous solution for nucleation containing at least a nickel-containing ion donor and a cobalt-containing ion donor is controlled so that the pH value at a liquid temperature of 30°C is 10.2 to 12.5, thereby eliminating fine powder in the reaction solution. Micropowder, to obtain the nucleation base solution in which the crystal nucleus particle size is normally distributed; and

[0034] Particle growth process: Control the nucleation base solution so that the pH value at 30°C is 10.2 to 12.5, so that the nuclei in the nucleation base solution grow and obtain a nickel-cobalt binary cathode material precursor .

[0035] The method improves the conventional co-precipitation method, and first controls the pH value of the reaction to be 10.2-12.5 through the micropowder elimination process, so that the r...

Embodiment 1

[0058]1. Soluble nickel sulfate and cobalt sulfate are dissolved in pure water according to the ratio of nickel and cobalt elements to 1:1, and the nickel-cobalt mixed solution with a molar concentration of metal elements of 1.0mol / L is prepared, and 10wt.% Ammonia solution as complexing agent.

[0059] 2. The micropowder elimination reaction kettle uses pure water as the bottom liquid, the temperature is raised to 30°C, the stirring speed is controlled at 150r / min, and the molar concentration of ammonium ions in the bottom liquid is adjusted to 0.05mol / L by adding ammonium sulfate, and the pH of the bottom liquid is The value is controlled at 10.20 under the liquid temperature reference of 30°C.

[0060] 3. Add nickel salt and cobalt salt mixed solution, 10wt.% sodium hydroxide solution, and ammonia solution into pure water in parallel with 3 metering pumps, the flow rate of nickel-cobalt mixture is 100ml / min, and the flow rate of ammonia solution Control to ensure that the ...

Embodiment 2

[0066] 1. Soluble nickel chloride and cobalt chloride are dissolved in pure water according to the ratio of nickel and cobalt elements to 4:1, and the nickel-cobalt mixed solution with a molar concentration of metal elements of 3.0mol / L is prepared, and 30wt.% ammonium chloride solution as complexing agent.

[0067] 2. The micropowder elimination reaction kettle uses pure water as the bottom liquid, the temperature rises to 80°C, the stirring speed is controlled at 900r / min, and the molar concentration of ammonium ions in the bottom liquid is adjusted to 0.15mol / L by adding ammonium sulfate, and the pH of the bottom liquid is The value is controlled at 12.50 under the liquid temperature reference of 30°C.

[0068] 3. Add nickel salt and cobalt salt mixed solution, 30wt.% sodium hydroxide solution, and ammonium chloride solution into pure water in parallel with 3 metering pumps. The flow rate of nickel-cobalt mixed solution is 800ml / min. The flow rate control of the ammonium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com