A Hot Stamping Process for Improving the Strength of Hot Stamped Axle Housing Steel Finished Products

A technology for hot stamping and axle housing steel, applied in the field of iron and steel smelting and rolling, which can solve problems such as strength reduction, and achieve the effects of reducing heating temperature, excellent surface quality, and saving electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

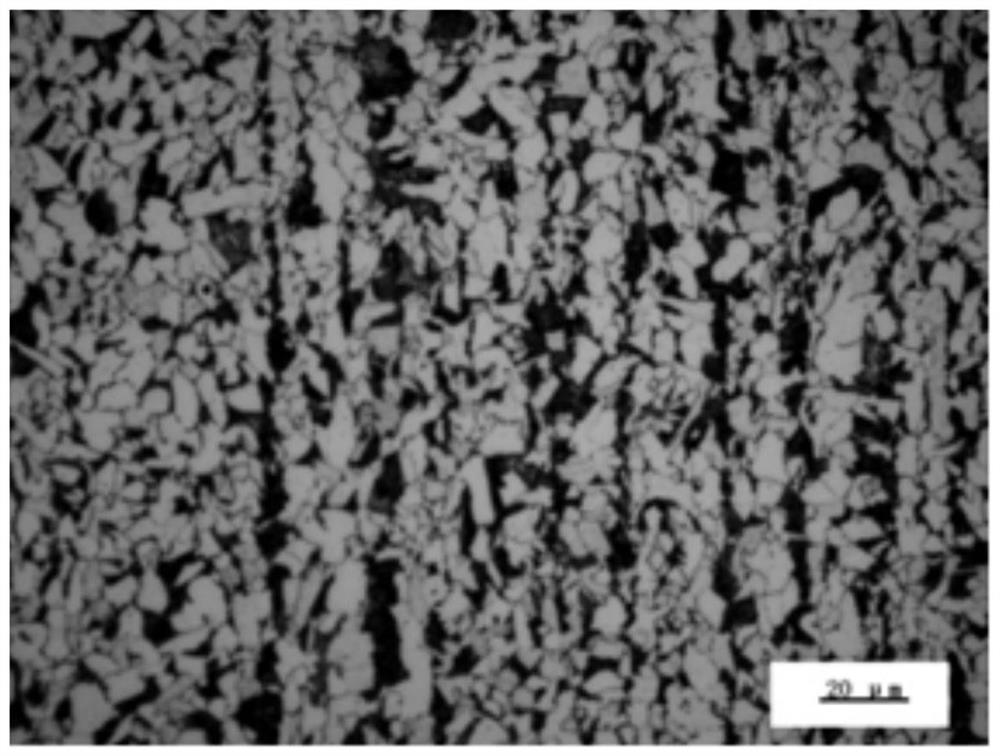

Image

Examples

preparation example Construction

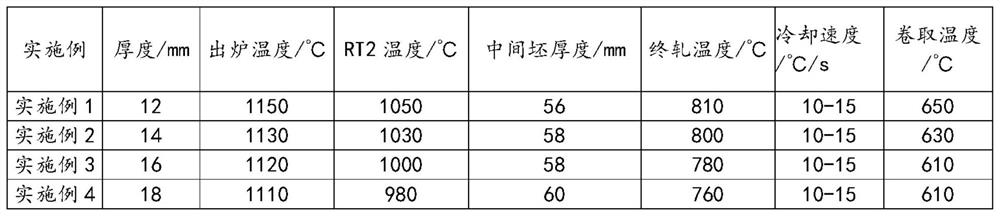

[0052] As some optional implementations, the preparation method of the axle housing steel material includes the following steps:

[0053] Continuous casting slabs are obtained by smelting molten iron, and the continuous casting slabs are composed of the following chemical elements in mass fractions: C: 0.26-0.30%; Si: 0-0.1%; Mn: 1.8-2.2%; P: ≤0.010%; S: ≤0.005%; Al: 0.02-0.05%; V: 0.01-0.03%; N: 0-0.003%; the rest is Fe and unavoidable impurities;

[0054] heating the continuous casting slab and keeping it warm;

[0055] performing rough rolling on the heated and heat-preserved continuous casting slab to obtain an intermediate slab;

[0056] Finish rolling the intermediate slab to obtain steel strip;

[0057] laminar cooling of the steel strip and coiling to obtain a hot-rolled steel coil;

[0058] After the hot-rolled steel coil is cooled to room temperature, it is coiled to obtain an axle housing steel material.

[0059] As some optional implementations, the holding tem...

experiment example

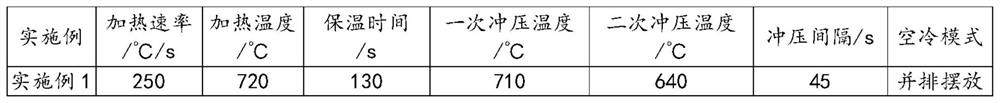

[0075] The axle housing steel materials and finished axle housing steel products prepared in Examples 1-3 were subjected to mechanical property tests, and the test results are shown in Table 4.

[0076] Table 4

[0077]

[0078] As can be seen from Table 4, the yield strength and tensile strength of the axle housing steel finished products produced by the hot stamping process for improving the strength of the hot stamping axle housing steel products provided by the present invention are all less than 50 MPa, and the axle housing surface quality is excellent at the same time , due to the use of a lower heating temperature, saving electricity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com