Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems that limit the development of perovskite solar cells, achieve the effects of suppressing the recombination of dark current, increasing current and opening voltage, filling factor, and improving surface morphology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

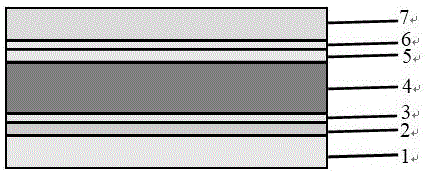

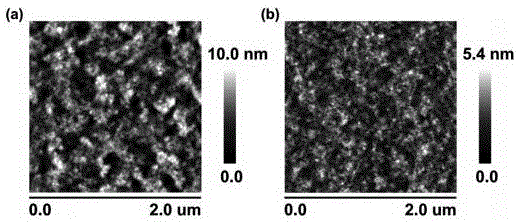

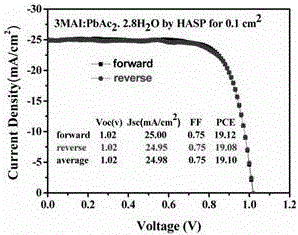

[0032] The perovskite layer is prepared using a new perovskite material 3MAI: PbAc 2 ·xH 2 O preparation, based on lead acetate (PbAc 2 ·xH 2 O) and methylamine iodine (MAI) dissolved in N,N-dimethylformamide (DMF) at a molar ratio of 1:3 to prepare a perovskite precursor solution with a mass fraction of 30%-50%, preferably x=2.8 H 2 O, the preferred mass fraction is 46%, and the perovskite layer is prepared at low temperature (<100ºC) by rapid preheating of the substrate and heating of the perovskite precursor solution, i.e. heat-assisted spin coating. Metal Au is used as the metal electrode layer, and its specific preparation steps are as follows.

[0033] (1) On the cleaned UV-treated transparent FTO conductive glass substrate, a dense hole transport layer was obtained by spin-coating PEDOT:PSS aqueous solution, and heat-treated at 140 ºC for 20 minutes to form a hole transport layer with a thickness of 50nm about.

[0034] (2) A 0.03 mg / ml 1-ethyl-3-methylimidazolium ...

Embodiment 2

[0041] The perovskite layer is prepared using a new perovskite material 3MAI: PbAc 2 ·xH 2 O preparation, based on lead acetate (PbAc 2 ·xH 2 O) and methylamine iodine (MAI) dissolved in N,N-dimethylformamide (DMF) at a molar ratio of 1:3 to prepare a perovskite precursor solution with a mass fraction of 30%-50%, preferably x=2.8 H 2 O, the preferred mass fraction is 46%, and the perovskite layer is prepared at low temperature (<100ºC) by rapid preheating of the substrate and heating of the perovskite precursor solution, i.e. heat-assisted spin coating. Metal Au is used as the metal electrode layer, and its specific preparation steps are as follows.

[0042] (1) On the cleaned UV-treated transparent FTO conductive glass substrate, a dense hole transport layer was obtained by spin-coating PEDOT:PSS aqueous solution, and heat-treated at 140 ºC for 20 minutes to form a hole transport layer with a thickness of 50nm about.

[0043] (2) A 0.03 mg / ml 1-ethyl-3-methylimidazolium ...

Embodiment 3

[0050] The perovskite layer is prepared using a new perovskite material 3MAI: PbAc 2 ·xH 2 O preparation, based on lead acetate (PbAc 2 ·xH 2 O) and methylamine iodine (MAI) dissolved in N,N-dimethylformamide (DMF) at a molar ratio of 1:3 to prepare a perovskite precursor solution with a mass fraction of 30%-50%, preferably x=2.8 H 2 O, the preferred mass fraction is 46%, and the perovskite layer is prepared at low temperature (<100ºC) by rapid preheating of the substrate and heating of the perovskite precursor solution, i.e. heat-assisted spin coating. Metal Au is used as the metal electrode layer, and its specific preparation steps are as follows.

[0051] (1) On the cleaned UV-treated transparent FTO conductive glass substrate, a dense hole transport layer was obtained by spin-coating PEDOT:PSS aqueous solution, and heat-treated at 140 ºC for 20 minutes to form a hole transport layer with a thickness of 50nm about.

[0052] (2) A 0.03 mg / ml 1-ethyl-3-methylimidazolium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com