Method for reinforcing laser cladding layer on surface of titanium alloy

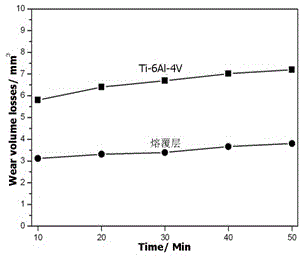

A technology of laser cladding and titanium alloy, which is applied in the coating process and coating of metal materials, can solve the problems of unstable surface morphology and wear resistance, reduce the content of brittle phase, etc., and achieve the improvement of surface morphology and durability Grinding performance, strong applicability, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Cut the Ti-6Al-4V alloy into a cuboid with a length of 30 mm, a width of 10 mm, and a thickness of 10 mm. Before mixing powder coating, clean the surface of titanium alloy, wipe down and blow dry. Then, the mass fraction of 70% Al 3 Ti, 10% C by mass fraction, 15% TiB by mass fraction 2 , The mixed powder with a mass fraction of 5% Cu is laser-clad on its 30mm×10mm surface.

[0063] The specific process steps are as follows:

[0064] (1) Weigh Al respectively 3 Ti alloy powder 0.70g, C powder 0.10g, TiB 2 Cu powder 0.15g, Cu powder 0.05g, pour the weighed powder into a small beaker, and use the water glass solution with a modulus of 2.2 to 3.7 to evenly stir the mixed powder into a paste. Base powder size 20~300μm, C, TiB 2 , Cu powder size 20 ~ 300μm.

[0065] (2) Evenly coat the paste-like mixed powder on the surface of the titanium alloy with a thickness of 0.3-2 mm, and let it dry naturally.

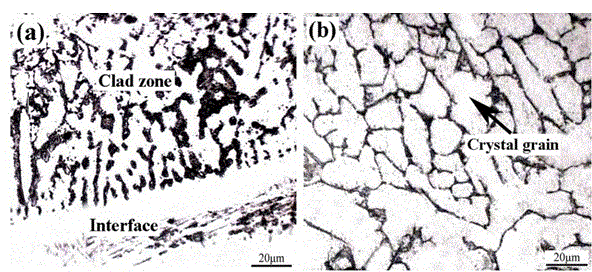

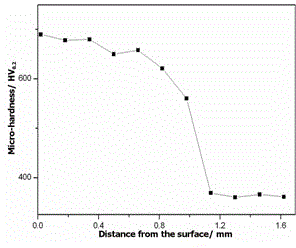

[0066] (3) Laser cladding is carried out on the surface of the ab...

Embodiment 2

[0073] Cut the Ti-6Al-4V alloy into a cuboid with a length of 30 mm, a width of 10 mm, and a thickness of 10 mm. Before mixing powder coating, clean the surface of titanium alloy, wipe down and blow dry. Then, the mass fraction is 65% Al 3 Ti, mass fraction is 10% C, mass fraction is 15% TiB 2 , with a mass fraction of 10% Cu mixed powder laser cladding on its 30mm×10mm surface.

[0074] The specific process steps are as follows:

[0075] (1) Weigh Al respectively 3 Ti alloy powder 0.65g, C powder 0.10g, TiB 2 Cu powder 0.15g, Cu powder 0.10g, pour the weighed powder into a small beaker, and use the water glass solution with a modulus of 2.2 to 3.7 to evenly stir the mixed powder into a paste. Base powder size 20~300μm, C, TiB 2 , Cu powder size 20 ~ 300μm.

[0076] (2) Evenly coat the paste mixed powder on the surface of the titanium alloy with a thickness of 0.3-2mm, and let it dry naturally.

[0077] (3) Laser cladding is carried out on the surface of the above-ment...

Embodiment 3

[0085] Cut the Ti-6Al-4V titanium alloy into a cuboid with a length of 30 mm, a width of 10 mm, and a thickness of 10 mm. Before mixing powder coating, clean the surface of titanium alloy, wipe down and blow dry. Then, Fe and Al mixed powder with a mass fraction of 65%, C with a mass fraction of 15%, and TiB with a mass fraction of 15% 2 A mixed powder of Cu with a mass fraction of 5% is laser cladding on its 30mm×10mm surface, wherein the mass ratio of Al and Fe is between 1:1 and 1:2.

[0086] The specific process steps are as follows:

[0087] (1) Weigh 0.65g of Fe and Al mixed powder, 0.15g of C powder and TiB 2 Cu powder 0.15g, Cu powder 0.05g, wherein the mass ratio of Al and Fe is between 1:1 and 1:2. Pour the weighed powder into a small beaker, and use the water glass solution with a modulus of 2.2 to 3.7 to evenly stir the mixed powder into a paste. Base powder size 20~300μm, C, TiB 2 , Cu mixed powder size 20 ~ 300μm.

[0088] (2) Evenly coat the paste mixed po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com