Dye-sensitized solar cell photo-anode and preparing method and application thereof

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve problems such as poor photoelectric performance, achieve good industrial application prospects, simple process, and good photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

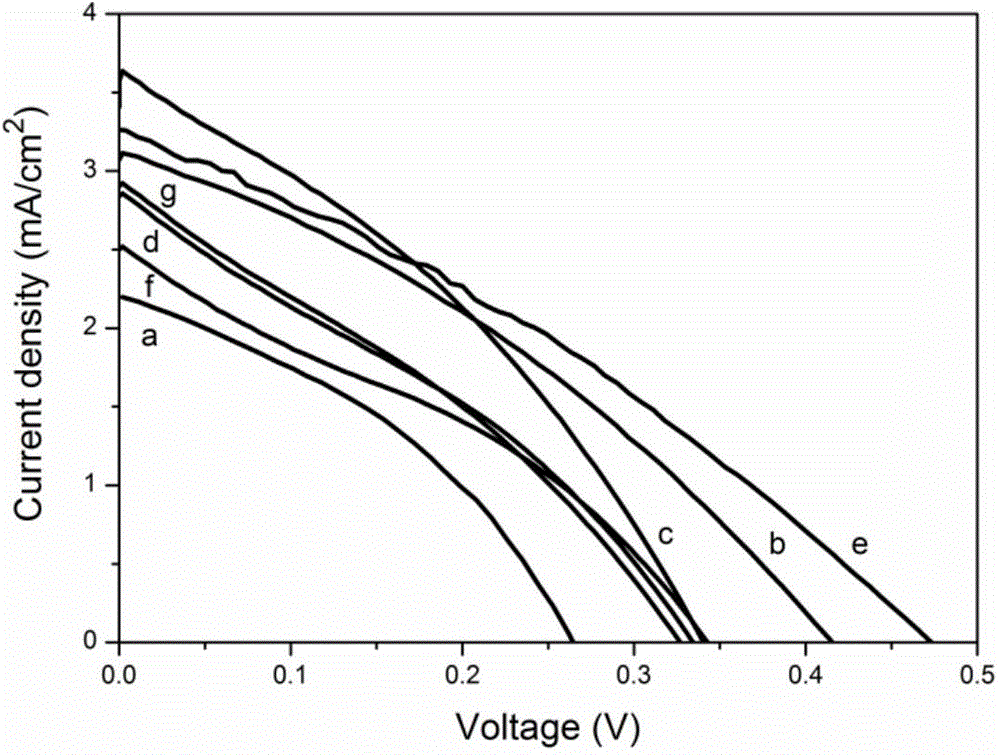

[0025] A method for preparing a photoanode of a dye-sensitized solar cell, comprising the steps of,

[0026] Step S1: heat-treating the dopant and tungsten trioxide in acid to obtain a powder, wherein the dopant is an oxide of metal M or a salt of metal M, and the metal M can be dissolved in the acid into the lattice of tungsten trioxide and the atomic orbitals of the metal M and W 5d Orbitals can be hybridized.

[0027] In particular, the metal M is selected from at least one of alkaline earth metal elements and transition metal elements. Preferably, the metal M is at least one selected from hafnium, strontium and cobalt.

[0028] Preferably, the dopant is an oxide of metal M. More preferably, the oxide of metal M is hafnium oxide (HfO 2 ), strontium oxide (SrO) and cobalt oxide (CoO).

[0029] In particular, the molar ratio of dopant to tungsten trioxide is 5˜50:100.

[0030] In particular, the acid is at least one of sulfuric acid and nitric acid. Preferably, concent...

Embodiment 1

[0052] Dissolve 7.5g ammonium metatungstate in 6.0mL water to obtain ammonium metatungstate solution, dissolve 2g polyvinylpyrrolidone in 15.0mL water to obtain polyvinylpyrrolidone solution, dissolve 4g polyethylene glycol 1000 in water to obtain polyethylene glycol solution. The ammonium metatungstate solution was added to the polyvinylpyrrolidone solution, ultrasonicated for 15 minutes, then stirred at room temperature for 2 hours, then polyethylene glycol solution was added, and stirred at room temperature for 2 hours to obtain a sol. Dry the sol at 80°C, then calcinate at 600°C for 1 hour, and obtain tungsten trioxide after cooling.

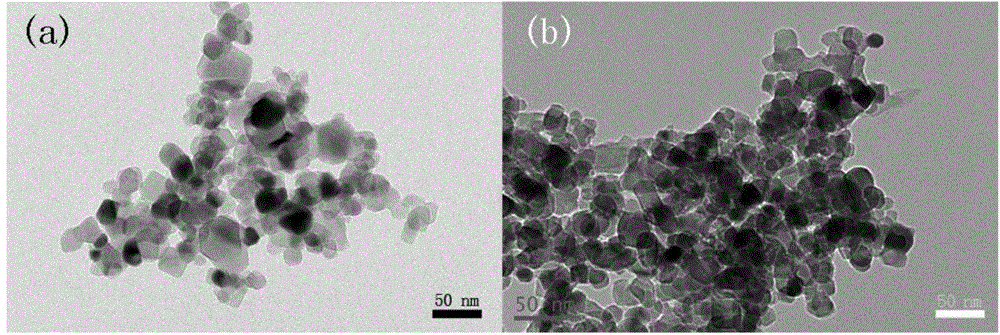

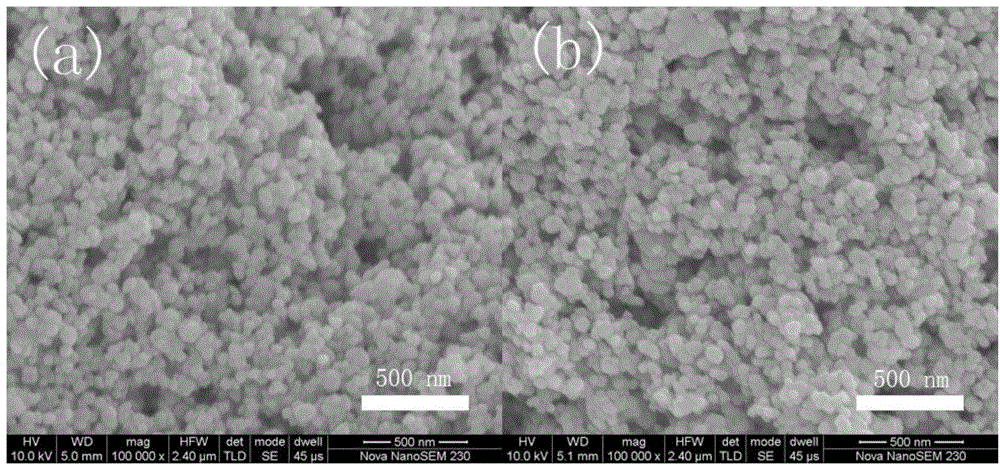

[0053] Dissolve and disperse 31.78mg of hafnium oxide in 50mL of concentrated sulfuric acid (ice bath), then add 0.35g of tungsten trioxide and stir at room temperature for 10min, then transfer to a reaction kettle and react at 100°C for 12h. After cooling, centrifuge and wash with deionized water and ethanol three times, and dry at 120° C....

Embodiment 2

[0057] Dissolve 7.5g ammonium metatungstate in 6.0mL water to obtain ammonium metatungstate solution, dissolve 1g polyvinylpyrrolidone in 15.0mL water to obtain polyvinylpyrrolidone solution, dissolve 6g polyethylene glycol 1000 in water to obtain polyethylene glycol solution. The ammonium metatungstate solution was added to the polyvinylpyrrolidone solution, ultrasonicated for 15 minutes, then stirred at room temperature for 2 hours, then polyethylene glycol solution was added, and stirred at room temperature for 2 hours to obtain a sol. The sol was dried at 100°C, then calcined at 500°C for 2 hours, and tungsten trioxide was obtained after cooling.

[0058] Dissolve and disperse 62.53mg of strontium oxide in 50mL of 3M nitric acid (ice bath), then add 0.35g of tungsten trioxide and stir at room temperature for 20min, then transfer to a reaction kettle and react at 150°C for 8h. After cooling, centrifuge and wash with deionized water and ethanol three times, and dry at 200° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com