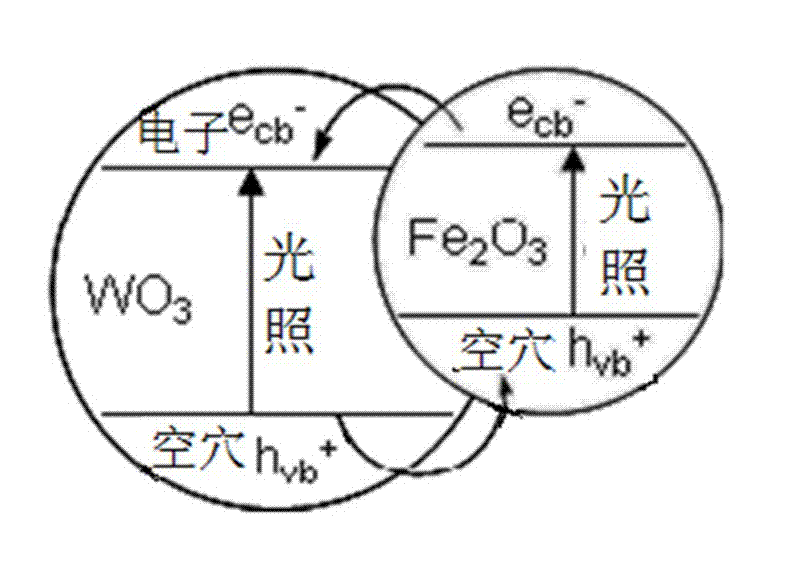

Iron-doped tungsten trioxide photocatalyst and preparation method thereof

A technology of tungsten trioxide and photocatalyst, which is applied in the field of catalysis, can solve the problems of unfavorable large-scale promotion and application, high cost, and violation of environmental protection, and achieve the effects of improved catalytic activity of ultraviolet light and visible light, easy operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Method 1 A preparation method 1 of an iron-doped tungsten trioxide photocatalyst, that is, a solid-phase mixing method, comprising the following steps:

[0033] 1) At room temperature, disperse the solid powder containing tungsten and iron in the aqueous solution under vigorous stirring to form a suspension. The conversion of tungsten and iron in the raw materials is WO 3 and Fe 2 o 3 Calculation, Fe 2 o 3 The doping amount is 0.1 ~ 90% (mass percentage, WO 3 % + Fe 2 o 3 % = 100%);

[0034] 2) The suspension was stirred and ultrasonicated to make it evenly mixed.

[0035]3) The suspension obtained in step 2 is 50 ~ 95 on the rotary evaporator 0 C evaporated to dryness.

[0036] 4) The powder obtained in step 3 is evaporated to dryness and ground in a muffle furnace at 200 ~ 950 0 C calcination activation, that is, iron-doped tungsten trioxide photocatalyst.

[0037] Method 2 The preparation method 2 of an iron-doped tungsten trioxide photocatalyst, namely th...

Embodiment 1

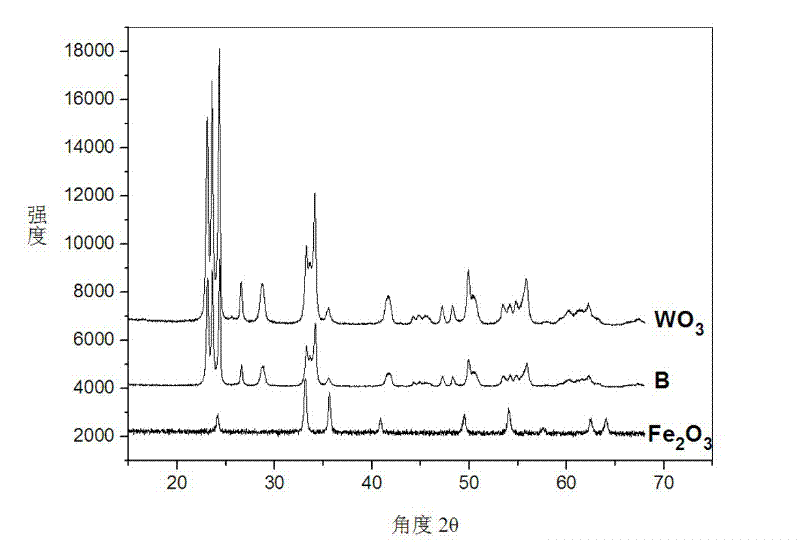

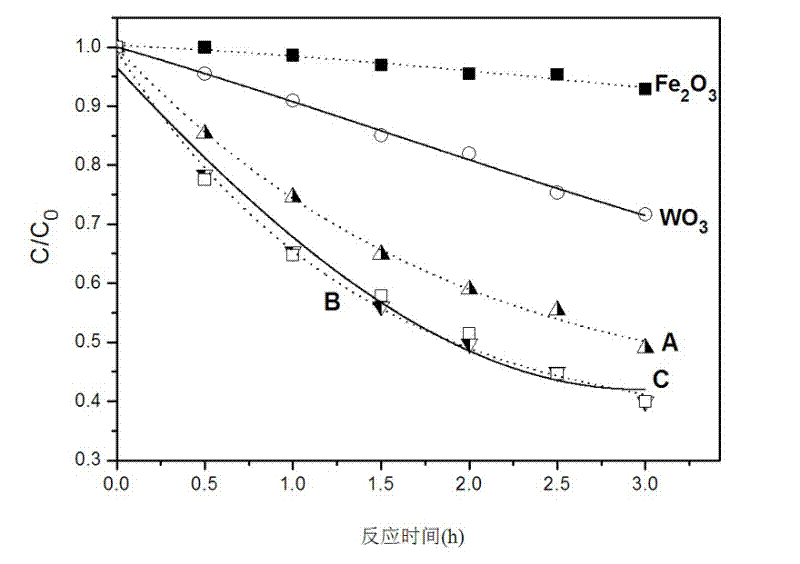

[0060] 0.002 g of amorphous iron oxide (Fe 2 o 3 ) and 1.998 g of tungsten trioxide were dispersed in 30 mL of water, stirred evenly, ultrasonicated for 30 min, and then 70 0 C evaporated to dryness. The evaporated powder was placed in a muffle furnace at 400 0 C was calcined for 3h to obtain doped 0.1 wt% Fe 2 o 3 Tungsten trioxide photocatalyst A (see Figure 1~3 middle line A). Using the above photocatalytic activity evaluation method, adding 10 mM H 2 o 2 , after 3 h irradiation under UV light, Fe 2 o 3 , tungsten trioxide and catalyst A were 7.15%, 28.4% and 50.96% respectively. Obviously, under the same conditions, Catalyst A is more effective than Fe 2 o 3 And tungsten trioxide has stronger UV photocatalytic activity.

Embodiment 2

[0062] 0.02 g of amorphous iron oxide (Fe 2 o 3 ) and 1.98 g of tungsten trioxide were dispersed in 30 mL of water, stirred evenly, ultrasonicated for 30 min, and then 70 0 C evaporated to dryness. The evaporated powder was placed in a muffle furnace at 400 0 C was calcined for 3h to obtain doped 1wt% Fe 2 o 3 Tungsten trioxide photocatalyst B (see Figure 1~3 middle line B). Using the above photocatalytic activity evaluation method, adding 10 mM H 2 o 2 , after 3 h irradiation under UV light, Fe 2 o 3 , tungsten trioxide and catalyst B were 7.15%, 28.4% and 60.07% respectively. Obviously, under the same conditions, the UV photocatalytic activity of catalyst B was higher than that of tungsten trioxide and Fe 2 o 3 There are several times the improvement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com