Diatomite coating capable of decomposing formaldehyde

A technology of diatom mud coating and formaldehyde, which is applied in the field of coatings, can solve the problems of low capacity and low rate of decomposition of formaldehyde, and achieve the effects of low cost, bright color and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

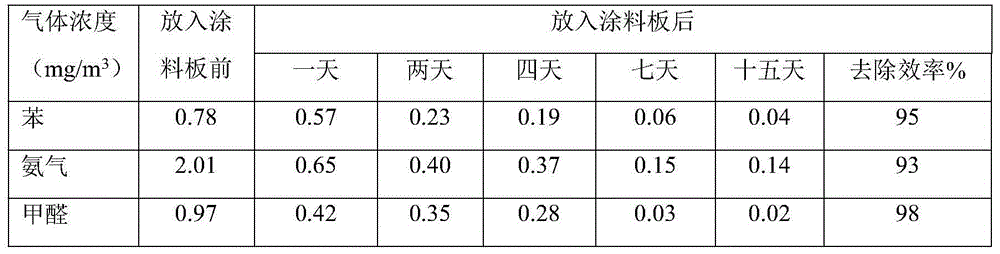

Embodiment 1

[0034]The diatom mud coating in the present embodiment, by mass percentage, this diatom mud coating comprises titanium dioxide 5%, nano-titanium dioxide 8%, white carbon black 5%, nano-calcium carbonate 2%, nano-silicon dioxide 5%, nanometer Tungsten trioxide 10%, medical stone powder 4%, tourmaline powder 2%, sepiolite material 6%, chitin 5%, graphene oxide 3%, mica powder 1%, nano activated carbon 7%, phthalocyanine compound 0.5%, and the balance is diatom mud.

[0035] The pH value of this diatom mud coating is 4, the particle diameter of nano-titanium dioxide is 5nm, the particle diameter of nano-tungsten trioxide is 4nm, the particle size of medical stone powder is 380 orders, and the particle size of tourmaline powder is 400 orders. The crystal form of the phthalocyanine compound is an α crystal form.

[0036] After adding appropriate amount of water to the diatom mud coating, apply it to the surface of the wooden board, the coating thickness is 2mm, and the coating are...

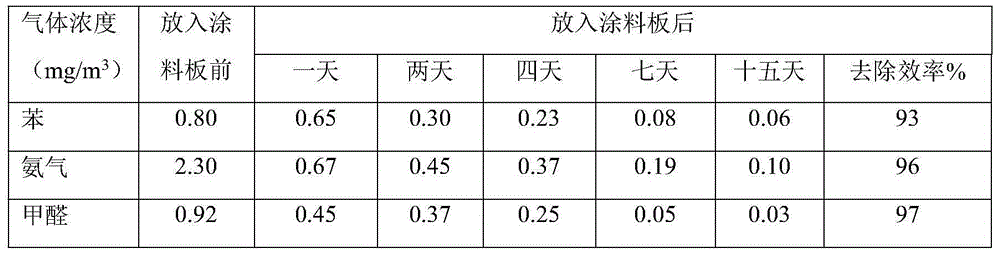

Embodiment 2

[0044] The diatom mud coating in the present embodiment, by mass percentage, this diatom mud coating comprises titanium dioxide 10%, nano-titanium dioxide 3%, white carbon black 2%, nano-calcium carbonate 3%, nano-silicon dioxide 4%, nanometer Tungsten trioxide 18%, medical stone powder 3%, tourmaline powder 1%, sepiolite material 8%, chitin 7%, graphene oxide 6%, mica powder 0.5%, nano activated carbon 1%, phthalocyanine compound 0.4%, the balance is diatom mud.

[0045] The pH value of this diatom mud coating is 6, the particle diameter of nano-titanium dioxide is 10nm, the particle diameter of nano-tungsten trioxide is 2nm, the particle size of medical stone powder is 500 orders, and the particle size of tourmaline powder is 600 orders. The phthalocyanine compound is aza-phthalocyanine, and its crystal form is A crystal form.

[0046] After adding appropriate amount of water to the diatom mud coating, apply it to the surface of the wooden board, the coating thickness is 2....

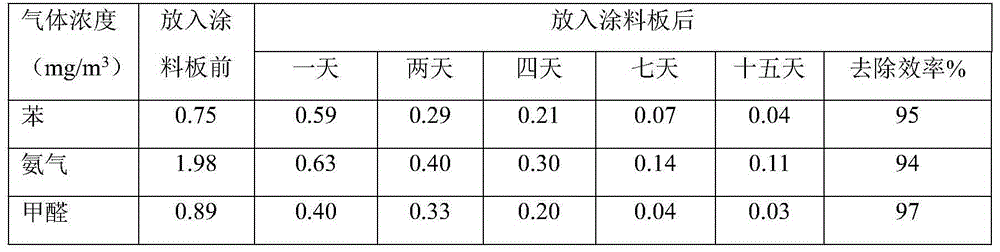

Embodiment 3

[0052] The diatom mud coating in the present embodiment, by mass percentage, this diatom mud coating comprises titanium dioxide 15%, nano titanium dioxide 10%, white carbon black 8%, nano calcium carbonate 2%, nano silicon dioxide 2%, nanometer Tungsten trioxide 6%, medical stone powder 5%, tourmaline powder 3%, sepiolite material 5%, chitin 6%, graphene oxide 3%, mica powder 1.3%, nano activated carbon 7%, phthalocyanine compound 0.45%, and the balance is diatom mud.

[0053] The pH value of this diatom mud coating is 5, the particle diameter of nano-titanium dioxide is 4nm, the particle diameter of nano-tungsten trioxide is 5nm, the particle size of medical stone powder is 600 orders, and the particle size of tourmaline powder is 550 orders. The phthalocyanine compound is metal-phthalocyanine, and its crystal form is Y crystal form.

[0054] After adding appropriate amount of water to the diatom mud paint, apply it to the surface of the wooden board, the coating thickness i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com