Recycling method of denitration catalyst waste and denitration catalyst prepared from denitration catalyst waste

A technology of denitration catalyst and recovery method, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalyst, etc. Use problems such as low efficiency to achieve the effects of low wear rate, strong pressure resistance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] - Preparation of denitrification catalyst recycle material

[0023] The denitrification catalyst waste is calcined at 700°C for 20 hours, and ground into 40-150um powder to obtain the denitrification catalyst recycle material.

[0024] Preparation of double denitrification catalyst

[0025] 60 parts of titanium dioxide; 3 parts of tungsten trioxide; 45 parts of denitrification catalyst reclaimed material; 1 part of vanadium pentoxide; 2 parts of glass fiber; 0.5 parts of citric acid solution with a mass percentage of 50%; 1 part of carboxymethyl cellulose; 3 parts of rare earth oxides are kneaded, extruded, dried, and calcined to obtain a denitrification catalyst recovery material composition, and its specification is 150×150×500mm 3 , 18 holes × 18 holes.

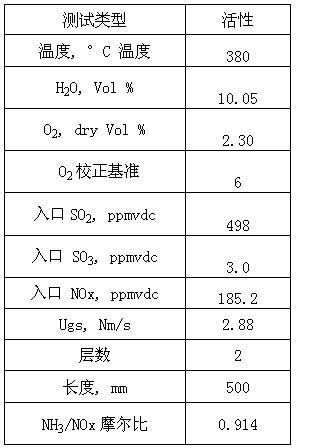

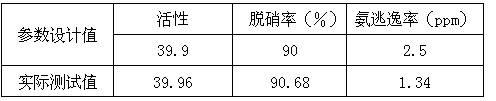

[0026] Three performance parameters detection

[0027] Tested by nitrogen adsorption method and specific surface area tester, the specific surface area of the denitrification catalyst prepared in this ex...

Embodiment 2

[0034] - Preparation of denitrification catalyst recycle material

[0035] The denitrification catalyst waste is calcined at 500°C for 10 hours, and ground into 150-250um powder to obtain the denitrification catalyst recycle material.

[0036] Preparation of double denitrification catalyst

[0037] 90 parts of titanium dioxide; 10 parts of tungsten trioxide; 1 part of denitration catalyst reclaimed material; 2 parts of vanadium pentoxide; 6 parts of glass fiber; 2 parts of citric acid solution with a mass percentage of 48%; , extrusion, drying, calcining, cutting and module assembly to obtain a denitrification catalyst recovery material composition, the specification of which is 150×150×900mm 3 , 18 holes × 18 holes.

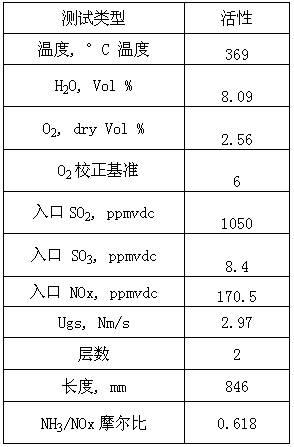

[0038] Three performance parameters detection

[0039] Tested by nitrogen adsorption method and specific surface area tester, the specific surface area of the denitrification catalyst prepared in this embodiment is 58㎡ / g; the void volume measured by ...

Embodiment 3

[0046] - Preparation of denitrification catalyst recycle material

[0047] The denitrification catalyst waste is calcined at 600° C. for 10 hours, and ground into a powder with a particle size of 150-250 μm to obtain a denitrification catalyst recycle material.

[0048] Preparation of double denitrification catalyst

[0049] 80 parts of titanium dioxide; 7 parts of tungsten trioxide; 30 parts of denitration catalyst reclaimed material; 1.5 parts of vanadium pentoxide; 4 parts of glass fiber; 1.2 parts of citric acid solution with a mass percentage of 52%; 4.8 parts of rare earth oxides are kneaded, extruded, dried, and calcined to obtain a denitrification catalyst recovery material composition, and its specification is 150×150×1500mm 3 , 18 holes × 18 holes.

[0050] Three performance parameters detection

[0051] Detected by nitrogen adsorption method and specific surface area tester, the specific surface area of the denitrification catalyst prepared in this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com