Tungstic trioxide nano-slice and preparation method thereof

A technology of tungsten trioxide and nanosheets, which is applied in the field of nanotechnology and new materials, can solve the problems that the preparation method of two-dimensional tungsten oxide has not been reported, and achieve the effect of large production scale, high efficiency and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

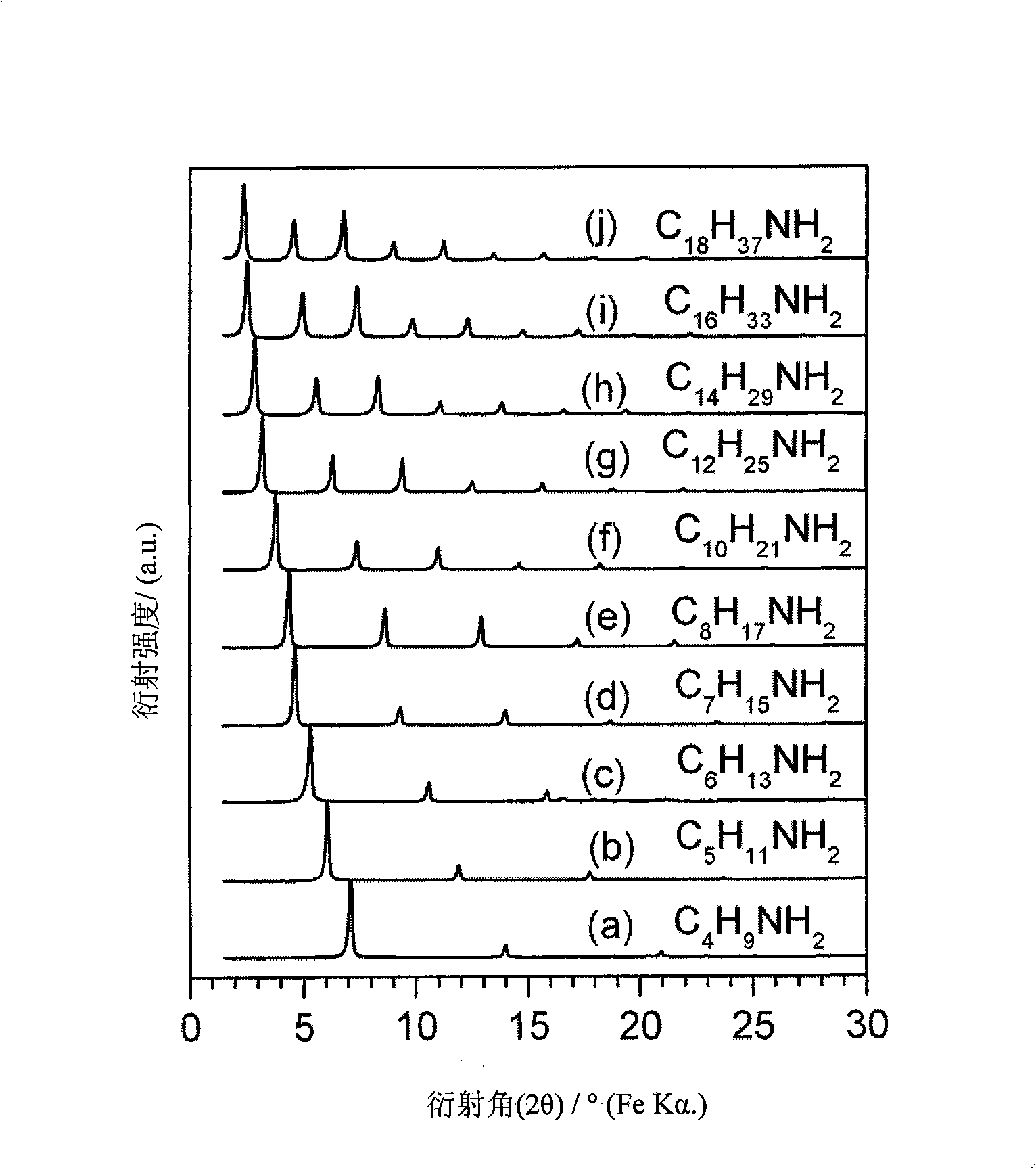

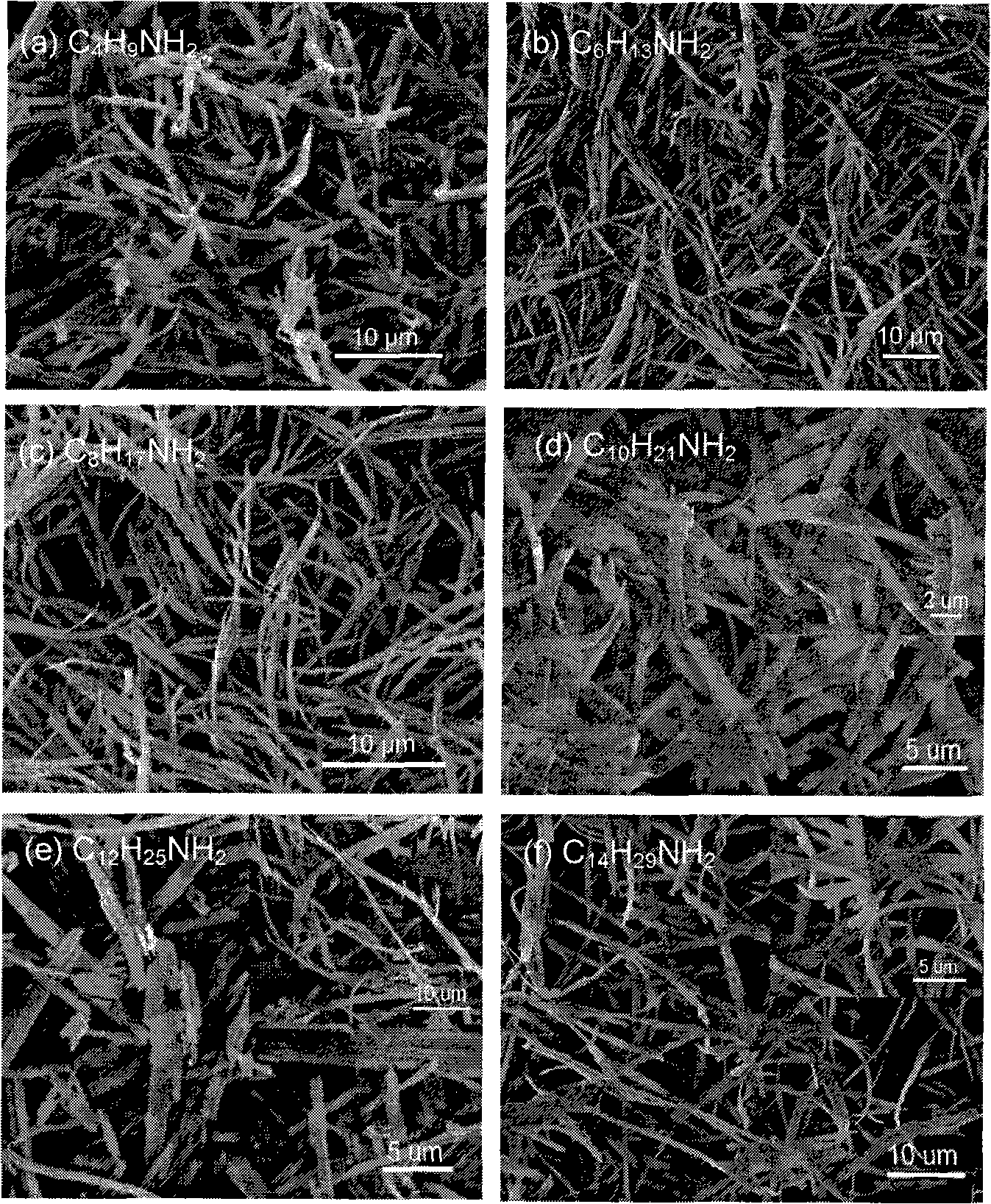

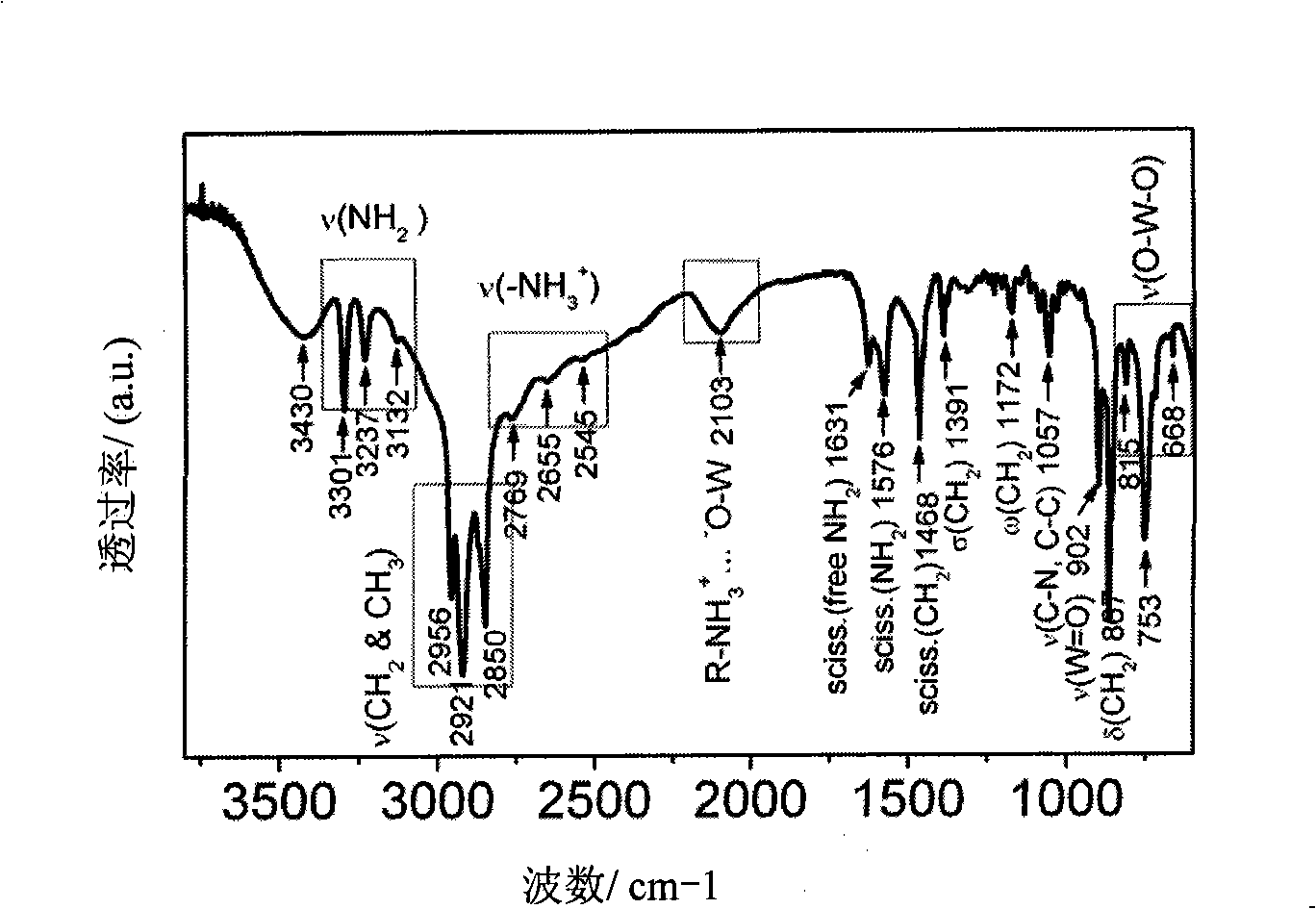

[0036] 10g, about 20mmol of H 2 W 2 o 7 2.5H 2 O dispersed in 66 mL of CH 3 (CH 2 ) 7 NH 2 with 330 mL of CH 3 (CH 2 ) 5 CH 3 NH 2 In the mixed solution, react at room temperature at 22°C under continuous stirring for 72 hours; centrifuge to obtain a white solid product, which is washed twice with hexane and ethanol respectively; the washed solid product is dried under reduced pressure at room temperature for 5 hours to obtain a white solid intermediate product. The X-ray diffraction spectrum of the product is as figure 1 As shown in e, it has typical two-dimensional layered structure characteristics, and the layer spacing is 2.59nm; its representative morphology is as follows figure 2 As shown in c, it is a quasi-one-dimensional band structure; its Fourier infrared spectrum is as follows image 3 , indicating that the obtained product is a tungstic acid-based organic / inorganic hybrid. Thermogravimetric analysis indicated that the blend had an inorganic content...

Embodiment 2

[0039] About 2 grams of WO, dried at 120°C 3 ·H 2 O nanosheets into Al 2 o 3 Crucible (covered); then put the crucible in an ordinary electric furnace, heat treatment in air atmosphere at 350°C for 5h, and control the heating rate at 2°C min -1 , and finally naturally cooled to room temperature to obtain 1.9 g of product. Its X-ray diffraction spectrum is as Figure 9 , indicating that the obtained product is also monoclinic tungsten oxide (WO 3 ).

Embodiment 3

[0041] 2.37 g of WO, dried at 120°C 3 ·H 2 O nanosheets into Al 2 o 3 Crucible (covered); then put the crucible in an ordinary electric furnace, heat treatment in an air atmosphere at 250°C for 5h, and control the heating rate at 2°C min -1 , and finally naturally cooled to room temperature to obtain 2.22 g of product. The X-ray diffraction spectrum and transmission electron microscope analysis result of gained product are respectively as follows Figure 10 , Figure 11 , indicating that the obtained product is monoclinic tungsten oxide (WO 3 ) nanosheets, and a single nanosheet is a single crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com