WO3 electrochromic thin film preparation method

A thin film preparation and electrochromic technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of difficult to enlarge the area of the thin film, expensive preparation cost, and high preparation requirements, and achieves good coloring efficiency, simple equipment, and easy preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the above-mentioned tungsten trioxide film is basically characterized in that it comprises the following specific processes:

[0042] (1) Clean the substrate, ultrasonically clean it in lye and acetone, clean it with deionized water, dry it, and set it aside.

[0043] (2) React tungsten powder with hydrogen peroxide for 5-7 hours, filter, then add absolute ethanol and glacial acetic acid to the filtrate, and stir evenly.

[0044] (3) Reflux at 50-60°C for 5-6 hours through a cooling reflux device to obtain uniform and transparent WO 3 Sol.

[0045] (4) the WO obtained above 3 The sol was distilled under reduced pressure in a rotary evaporator at 50-60°C to concentrate the sol concentration.

[0046] (5) Immerse the substrate in (1) in the above-mentioned sol for about 3 minutes, and the film pulls the substrate vertically upward at a speed of 2-3 cm / min.

[0047] (6) Repeat step (5) twice at an interval of 5 minutes, and then air dry natura...

Embodiment 1

[0050] (1) Clean the FTO conductive glass. (2) React 6.5g of 99.9% tungsten powder with a particle size below 1000nm and 40ml of 30% analytically pure hydrogen peroxide for 5-7 hours, filter, and then add 10.0ml of analytically pure anhydrous ethanol and analytically pure Glacial acetic acid 40.0ml, stir evenly. (3) The peroxypolytungstic acid generated in step (2) is more fully acetylated by cooling and refluxing. The reflux time is an important factor affecting the sol concentration. The reflux time is 6-10 hours to obtain tungsten trioxide sol. (4) Use a rotary evaporator to distill and concentrate the sol under reduced pressure to increase the concentration of the sol, and the vacuum degree of the decompression device is 0.07-0.09Mpa. (5) Place the substrate vertically on the WO obtained in (4) 3 In the sol, the immersion time is about 3 minutes, so that it is fully in contact with the sol, and the substrate is pulled up at a speed of 2-3cm / min evenly and vertically. Aft...

Embodiment 2

[0052] The difference from Example 1 is that 1 g of analytically pure OAD is added in step (3), and the rest of the steps are similar to Example 1.

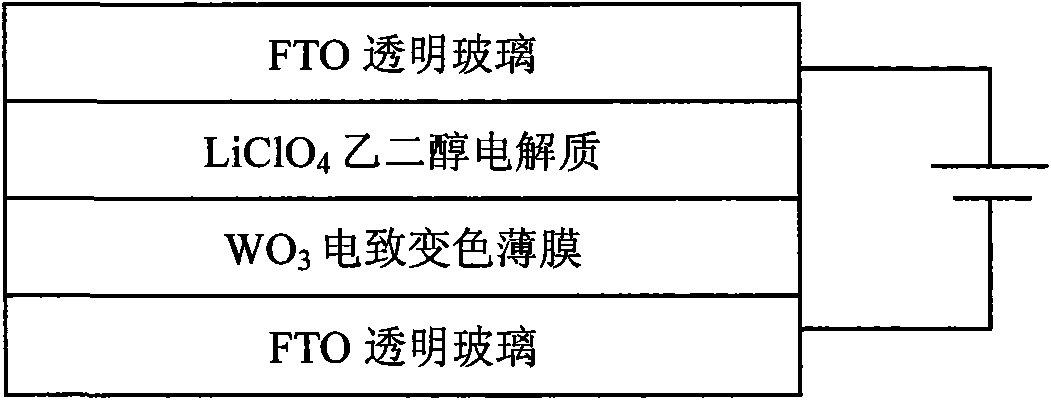

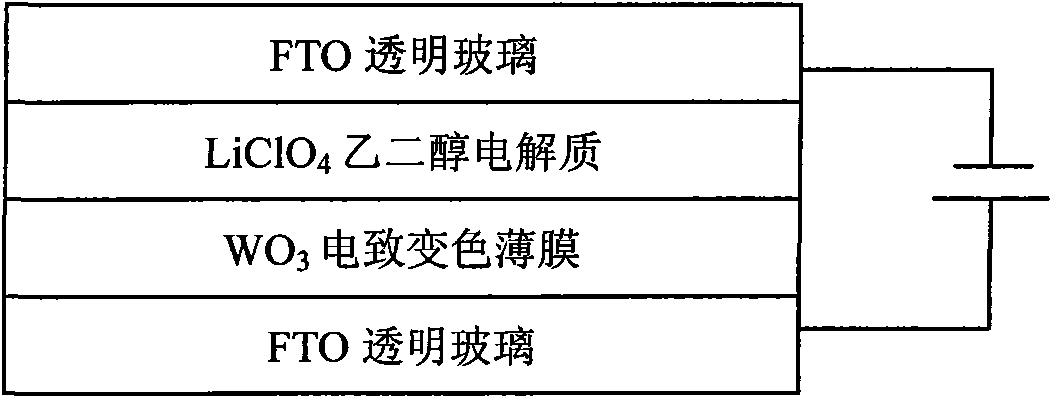

[0053] To the WO made by the present invention 3 The thin film is tested for light transmittance characteristics and cyclic voltammetry characteristics in the visible light band 400-750nm. with WO 3 As the working electrode, the counter electrode is Pt, Ag / AgCl is the reference electrode, 1.5mol / L LiClO 4 / Ethylene glycol solution is used as the electrolyte, and the cyclic voltammetry characteristics of the film are observed at the electrochemical workstation by using the three-electrode method. The scanning speed is 100mV / s, and the potential scanning range is -2-+2V, and the cycle test is performed continuously for 20 times.

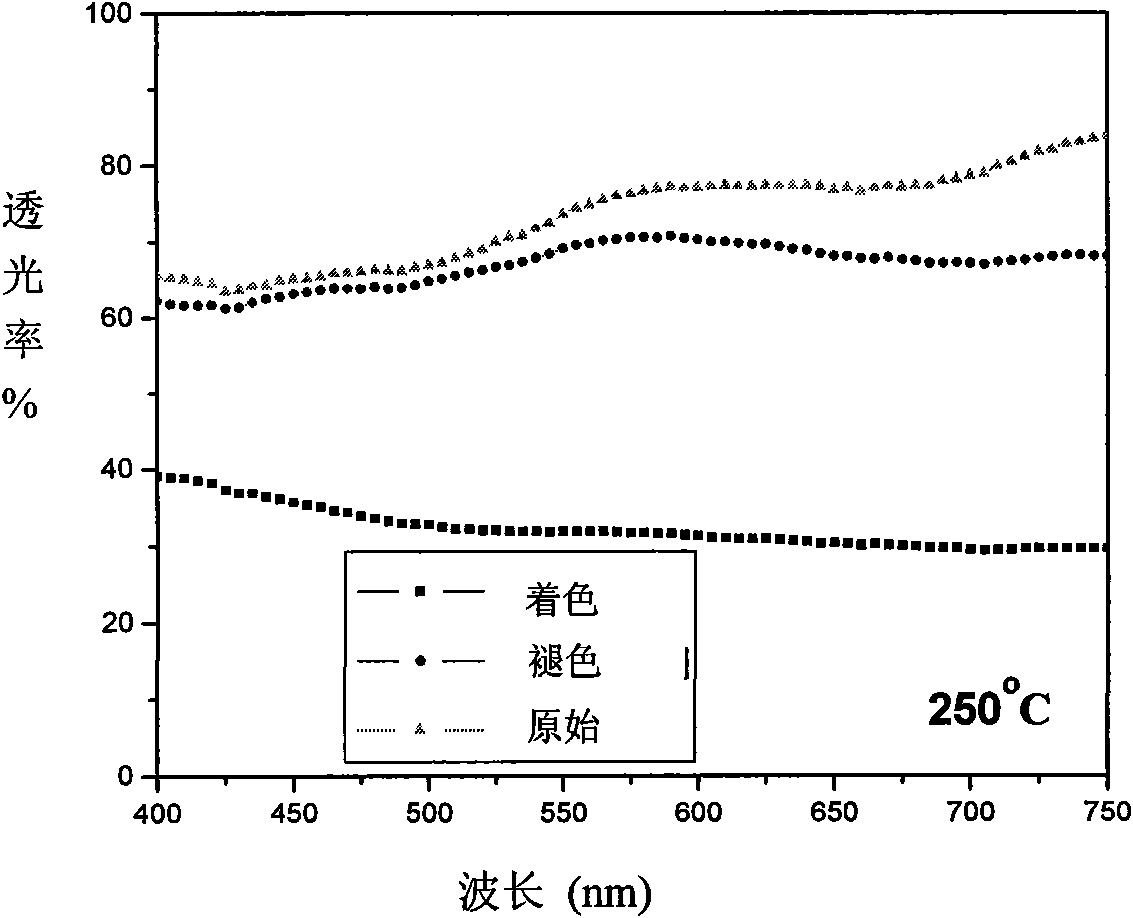

[0054] WO prepared by the present invention 3 The film has a light transmittance adjustment effect on the visible light band 400-750nm, according to figure 1 , figure 2 By changing the polarity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com