Oxide dispersion strengthened (ODS) steel preparing method and martensitic steel

A martensitic steel and dispersion strengthening technology, applied in the preparation of oxide dispersion strengthened steel, ODS low activity martensitic steel, martensitic steel field, can solve the problems of long process flow, high manufacturing cost, and prominent material heterogeneity and other problems, to achieve the effect of short process flow and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

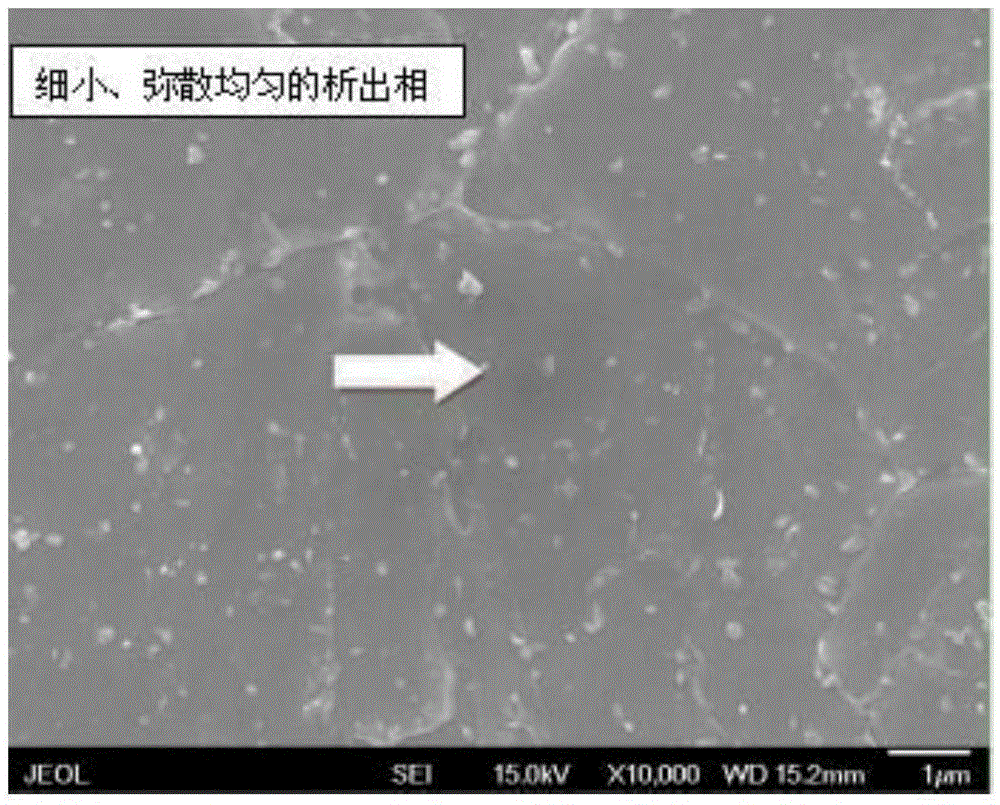

[0039]The invention is a preparation method of ODS steel. The basic principle is based on the strong binding energy between rare earth elements RE and O. Its standard molar enthalpy of formation is higher than that of oxides of other alloy elements, and it is very easy to form stable rare earth oxidation. Through the timing of adding rare earth elements and the way of introducing oxygen, the rare earth elements combine with oxygen to form fine oxide particles. For example, add an appropriate amount of iron oxide to the casting mold, add an appropriate amount of rare earth element yttrium to the fully deoxidized molten steel and cast it quickly. The yttrium in the molten steel captures the oxygen in the iron oxide to form yttrium oxide, which is dispersed in the molten steel. By controlling the oxygen content in molten steel and the addition of rare earth elements, the smelted ODS steel with uniform dispersion of rare earth oxides is obtained. The rare earth element in the pres...

Embodiment 1

[0049] A kind of preparation ODS martensitic steel based on above-mentioned method, its various compositions account for the percentage of total mass:

[0050] C: 0.09%, Cr: 8.9%, Mn: 0.51%, W: 2.09%, N: 0.055%, Ta: 0.12%, Ti: 0.45%, Si: 0.13%, V: 0.045%, Y: 0.07%, B2 o 3 : 0.14%; the finished product is made through the following steps:

[0051] (a) According to S1-S4 in the preparation method of the present invention, vacuum smelting is used to prepare steel ingots or continuously cast steel rods, with the following various components accounting for the percentage of the total mass:

[0052] C: 0.09%, Cr: 8.9%, Mn: 0.51%, W: 2.09%, N: 0.055%, Ta: 0.12%, Ti: 0.45%, Si: 0.13%, V: 0.045%, Y: 0.07%, B2 o 3 : 0.14%.

[0053] (b) first hot deformation by forging or rolling of ingots or continuously cast bars to obtain semi-finished products;

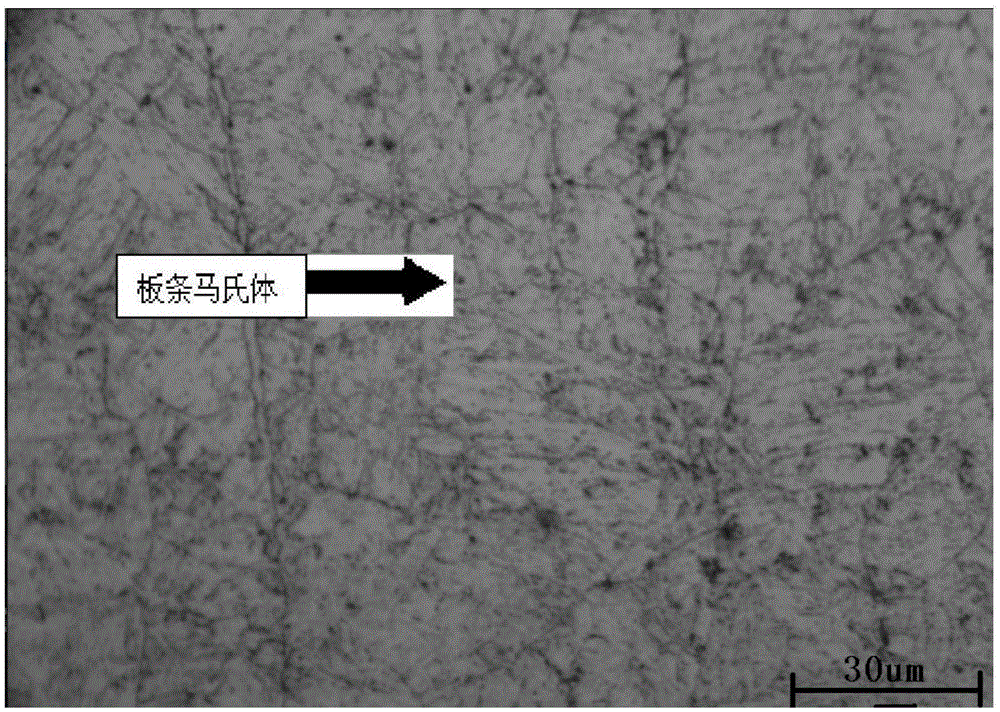

[0054] (c) heating the semi-finished product to 1150°C for austenitization, and deforming again by hot rolling until the required shap...

Embodiment 2

[0063] A kind of preparation ODS martensitic steel based on above-mentioned method, its various compositions account for the percentage of total mass:

[0064] C: 0.09%, Cr: 9.3%, Mn: 0.55%, W: 2.5%, N: 0.06%, Ta: 0.19%, Ti: 0.53%, Si: 0.13%, V: 0.045%, Y: 0.2%, B2 o 3 : 0.4%; the finished product is made through the following steps:

[0065] (a) According to S1-S4 in the preparation method of the present invention, vacuum smelting is used to prepare steel ingots or continuously cast steel rods, with the following various components accounting for the percentage of the total mass:

[0066] C: 0.09%, Cr: 9.3%, Mn: 0.55%, W: 2.5%, N: 0.06%, Ta: 0.19%, Ti: 0.53%, Si: 0.13%, V: 0.045%, Y: 0.2%, B2 o 3 : 0.4%.

[0067] (b) first hot deformation by forging or rolling of ingots or continuously cast bars to obtain semi-finished products;

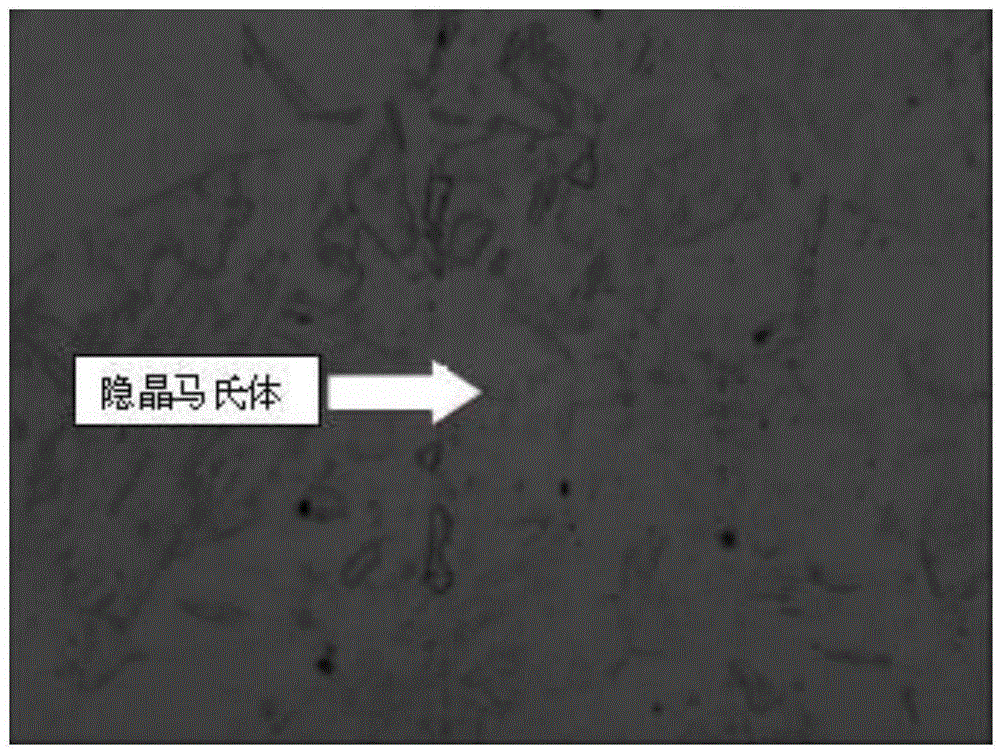

[0068] (c) heating the semi-finished product to 1200°C for austenitization, and then deforming again by hot rolling until the required shape a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com