Production method of tobacco sheets

A technology of tobacco sheet and production method, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that it is difficult to effectively adsorb nanomaterials, cannot change the microstructure, and affect the smoking quality of cigarettes, and achieve excellent stability and repeatability , unique style characteristics, obvious fragrance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

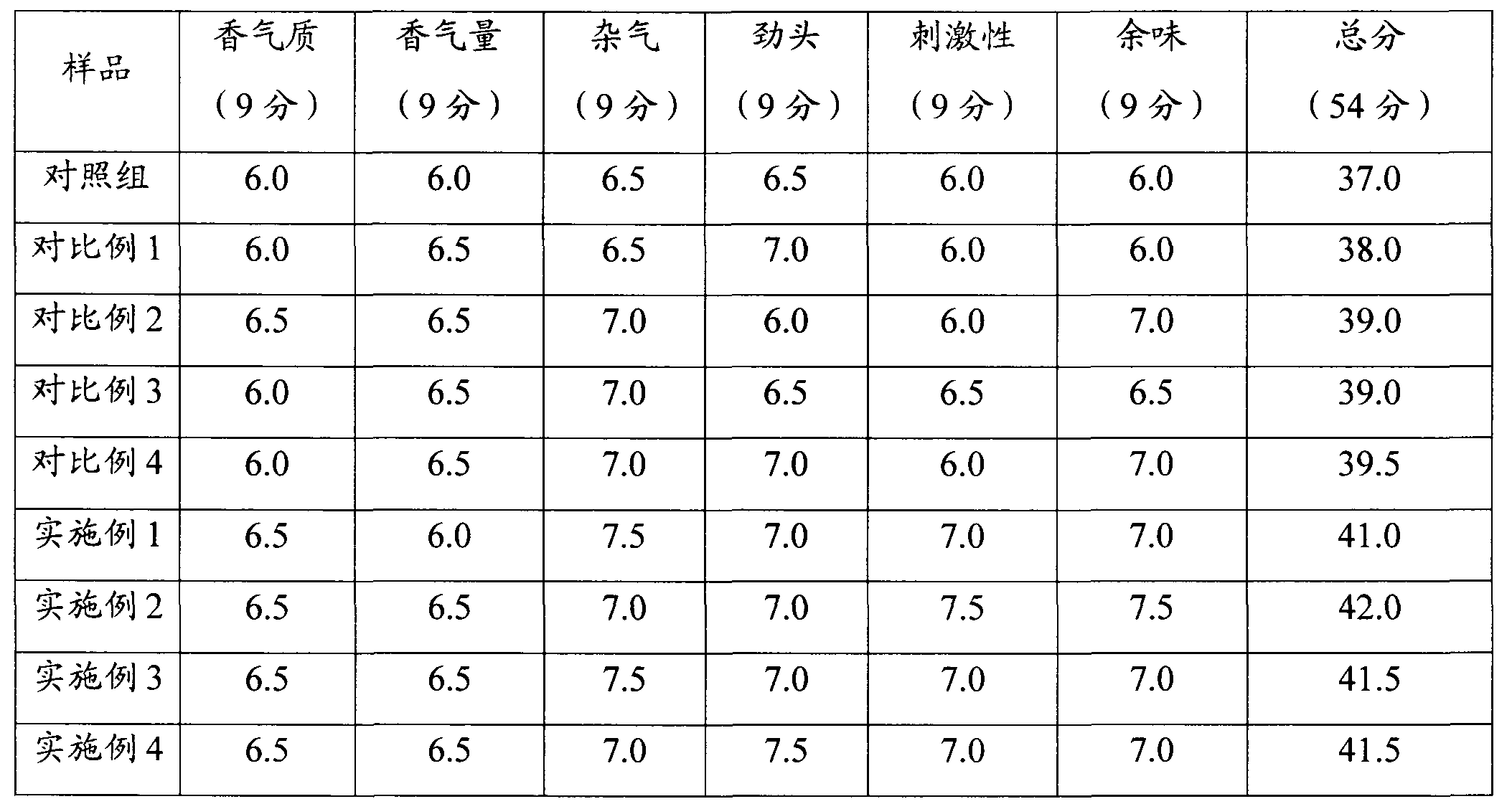

Examples

Embodiment 1

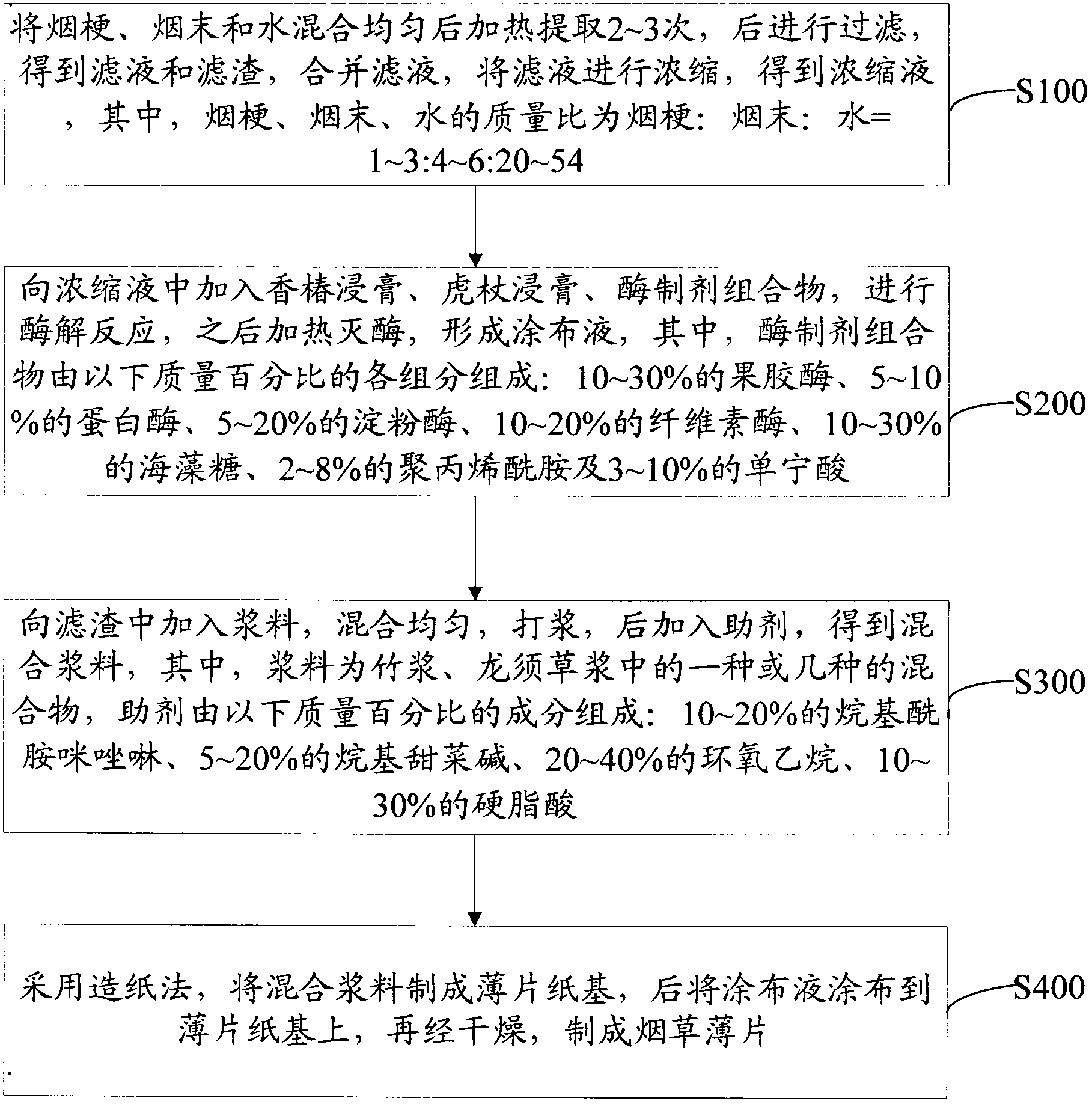

[0040] A production method of tobacco sheet, comprising the following steps:

[0041] (1) mechanically crushing the tobacco stems to a length of 10 mm, mixing 500 g of tobacco stems, 2500 g of tobacco dust and 25000 g of water, heating and extracting 3 times, and then filtering to obtain filtrate and filter residue, merging the filtrate, and carrying out the filtrate. Concentrated to obtain a concentrated solution with a density of 1.16 g / mL.

[0042] The pore size of the filter membrane required for filtration is 1 μm.

[0043] (2) Toon extract, Polygonum cuspidatum extract, and enzyme preparation composition are added to the concentrated solution to carry out enzymatic hydrolysis reaction, and then heated to 90° C. for 10 minutes to inactivate enzymes to form a coating solution.

[0044] Wherein, the enzyme preparation composition is composed of the following components in mass percentage: 30% pectinase, 10% protease, 20% amylase, 10% cellulase, 15% trehalose, 5% Polyacryl...

Embodiment 2

[0049] A production method of tobacco sheet, comprising the following steps:

[0050] (1) mechanically crushing the tobacco stems to a length of 12 mm, mixing 600 g of tobacco stems, 800 g of tobacco powder and 6000 g of water, and then heating and extracting for 2 times, and then filtering to obtain filtrate and filter residue, merging the filtrate, and carrying out the filtrate. Concentrated to obtain a concentrated solution with a density of 1.21 g / mL.

[0051] The pore size of the filter membrane required for filtration is 3 μm.

[0052] (2) Toon extract, Polygonum cuspidatum extract, and enzyme preparation composition are added to the concentrated solution to carry out enzymatic hydrolysis reaction, and then heated to 90° C. for 10 minutes to inactivate enzymes to form a coating solution.

[0053] Wherein, the enzyme preparation composition is composed of the following components by mass percentage: 20% pectinase, 10% protease, 15% amylase, 15% cellulase, 25% trehalose, ...

Embodiment 3

[0058] A production method of tobacco sheet, comprising the following steps:

[0059] (1) mechanically crushing the tobacco stems to a length of 15 mm, mixing 400 g of tobacco stems, 1000 g of tobacco powder and 10800 g of water, heating and extracting twice, and then filtering to obtain filtrate and filter residue, merging the filtrate, and carrying out the filtrate. Concentrated to obtain a concentrated solution with a density of 1.25 g / mL.

[0060] The pore size of the filter membrane required for filtration is 3 μm.

[0061] (2) Toon extract, Polygonum cuspidatum extract, and enzyme preparation composition are added to the concentrated solution to carry out enzymatic hydrolysis reaction, and then heated to 90° C. for 10 minutes to inactivate enzymes to form a coating solution.

[0062] Wherein, the enzyme preparation composition is composed of the following components in mass percentage: 25% pectinase, 10% protease, 15% amylase, 20% cellulase, 20% trehalose, 5% Polyacryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com