Chemical preparation method of nanoscale zinc oxide powder

A nano-scale zinc oxide and zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of high energy consumption, harsh reaction conditions, unfavorable industrial production, etc., and achieve low reaction temperature and short reaction time , no pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

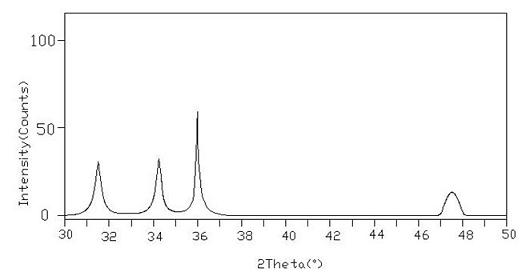

Image

Examples

Embodiment 1

[0023] (1) Prepare 1.5mo / L zinc sulfate solution and 30% sodium hydroxide solution, and slowly add 30% sodium hydroxide solution into the zinc sulfate solution in a water bath at 70°C to make the pH of the solution 11 (reaction During the process, the pH is not lower than 11), the stirring speed is 400 rpm, and the precipitation of zinc hydroxide and zinc oxide is obtained after reacting at 70°C for 1 hour;

[0024] (2) Filtrate and separate to obtain a solid zinc hydroxide and zinc oxide mixture, and wash the obtained solid mixture with distilled water for 7 to 8 times until there are no sulfate ions in the filtrate;

[0025] (3) Put the solid mixture obtained in step (2) into a flash dryer, flash, dry, and pulverize at 200°C to obtain 97% nano-sized zinc oxide powder with a particle diameter of 75nm. The whiteness of the powder is 8.5 grade.

Embodiment 2

[0027] (1) Prepare 1.0mo / L zinc sulfate and zinc chloride mixed solution (the ratio of the two can be arbitrary, in this example it is 1:1), and 35% potassium hydroxide solution, at 60°C Under water bath conditions, slowly add 35% potassium hydroxide solution into the mixed solution of zinc sulfate and zinc chloride to make the pH of the solution 12, stir at a speed of 400 rpm, and react at 60°C for 1 hour to obtain zinc hydroxide and Precipitation of zinc oxide;

[0028] (2) Filtrate and separate to obtain a solid zinc hydroxide and zinc oxide mixture, and wash the obtained solid mixture with distilled water for 7 to 8 times until there are no sulfate ions in the filtrate;

[0029] (3) Put the solid mixture obtained in step (2) into a flash dryer, flash, dry, and pulverize at 180°C to obtain 95% nano-sized zinc oxide powder with a particle diameter of 75nm. The whiteness of the powder is 8.5 grade.

Embodiment 3

[0031] (1) Prepare 2.0mo / L zinc nitrate and zinc chloride mixed solution (the ratio of the two is 1:1), and 35% sodium hydroxide and potassium hydroxide solution, and mix 35% Slowly add sodium hydroxide and potassium hydroxide solutions into zinc nitrate and zinc chloride solutions to make the pH of the solution 12, stir at a speed of 400 rpm, and react at 80°C for 1.5 hours to obtain precipitates of zinc hydroxide and zinc oxide ;

[0032] (2) Filtrate and separate to obtain a solid zinc hydroxide and zinc oxide mixture, and wash the obtained solid mixture with distilled water for 7 to 8 times until there are no sulfate ions in the filtrate;

[0033] (3) Put the solid mixture obtained in step (2) into a flash dryer, flash, dry, and pulverize at 250°C to obtain 99% nano-sized zinc oxide powder with a particle diameter of 95nm. The whiteness of the powder is 8.5 grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com