Method for preparing bifunctional mesoporous silica for adsorbing heavy metal ions in water

A technology of mesoporous silica and heavy metal ions, applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problem of adsorption and removal of heavy metal ions in water without dual-functional large-aperture mesoporous materials. and other issues, to achieve good application prospects, reduce production costs, and reduce pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

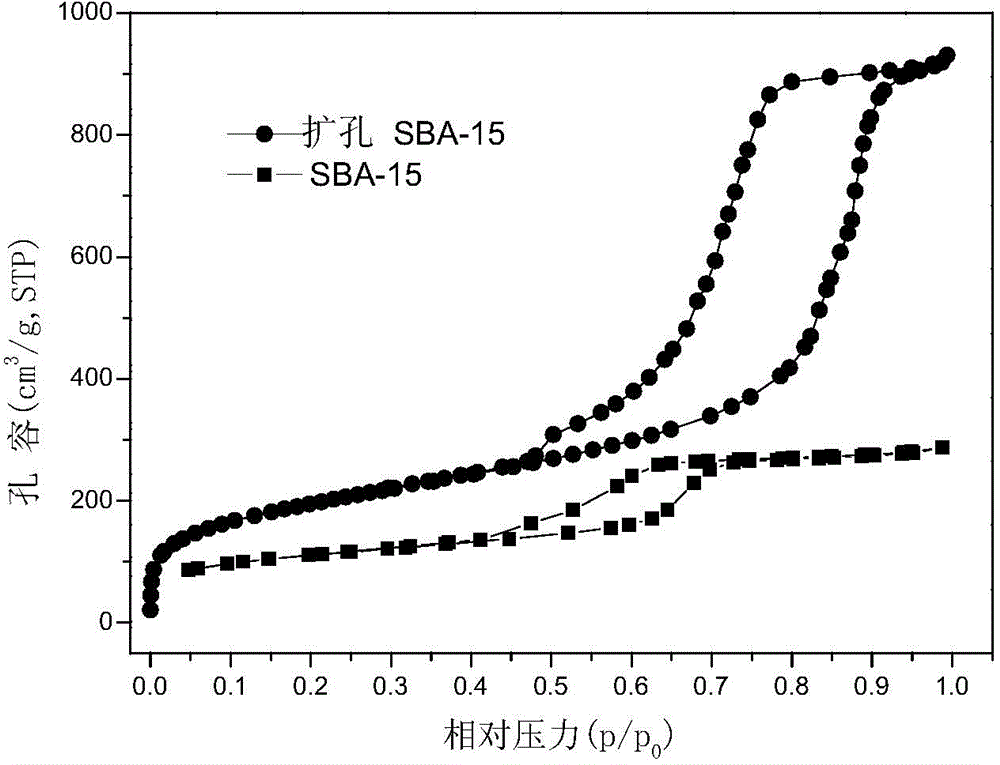

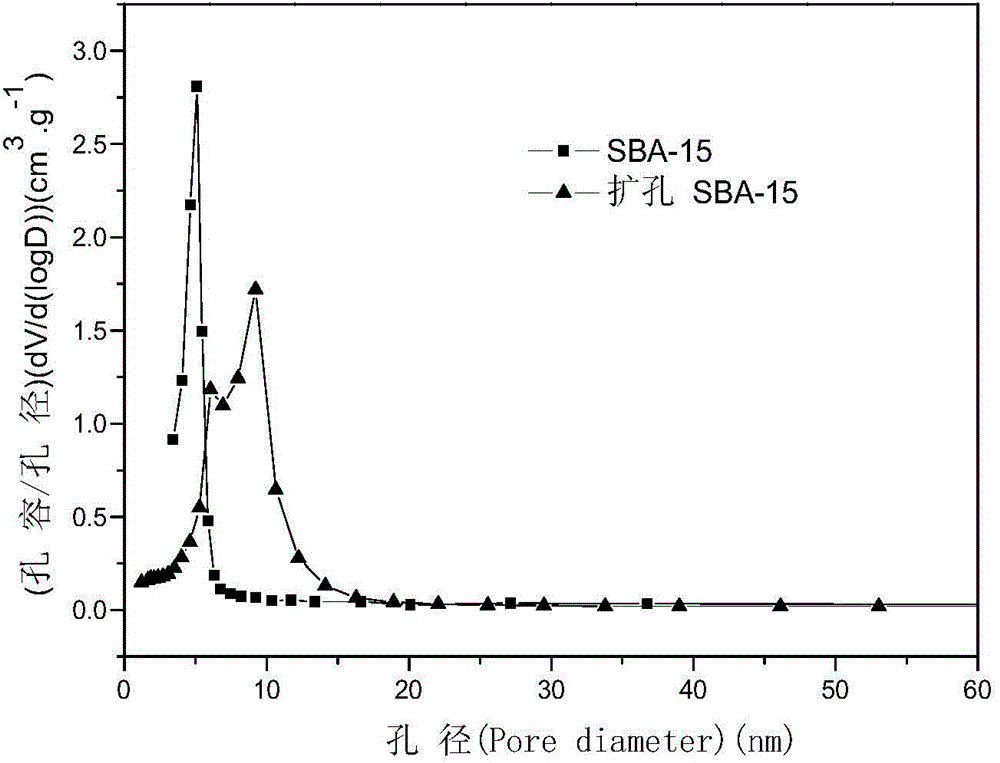

[0027] Synthesis of embodiment 1 large-aperture mesoporous silica

[0028] Add 4 g of structure directing agent P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer) into 150 mL (1.6 mol / L) of hydrochloric acid, stir for 2 h until the solution is clear, and raise the temperature to After reaching 40°C, add TMB (1,3,5-trimethylbenzene), said TMB / P123=1:5, react for 6 hours and use a constant pressure dropping funnel under rapid stirring (450r / min) for 6-9 Add 8.5g TEOS (tetraethyl orthosilicate) dropwise at a rate of 1 second / drop, continue to react at the same stirring speed for 24 hours, then transfer to a polytetrafluoroethylene high-pressure digestion tank, crystallize at 100°C for 24 hours, vacuum filter, and dry Dry the white powder, and dry the white powder with absolute ethanol and a small amount of concentrated hydrochloric acid at 98.5°C (the volume ratio of absolute ethanol and concentrated hydrochloric acid is 200:1), and extract it wit...

Embodiment 2 3

[0029] Example 2 Preparation of triamino-modified large-aperture mesoporous silica

[0030] Add 1.5-2.5g of mesoporous silica prepared in step 1 into a 250mL flat-bottomed flask filled with 50-100mL of toluene and mix evenly, add 3.5-4.5mmol of triaminosilane coupling agent, mix well, heat to reflux for 10h, Cool, then vacuum filter, wash with absolute ethanol 2-3 times, and dry in an oven at 80-120°C for 10-15h to obtain a sample.

[0031] After drying the sample prepared above, use 120ml of dichloromethane / diethyl ether mixture, and extract it with a Soxhlet extractor at 80°C for 8h, and dry the obtained solid at 100°C for 12h to obtain the triamino-modified of mesoporous silica.

Embodiment 3

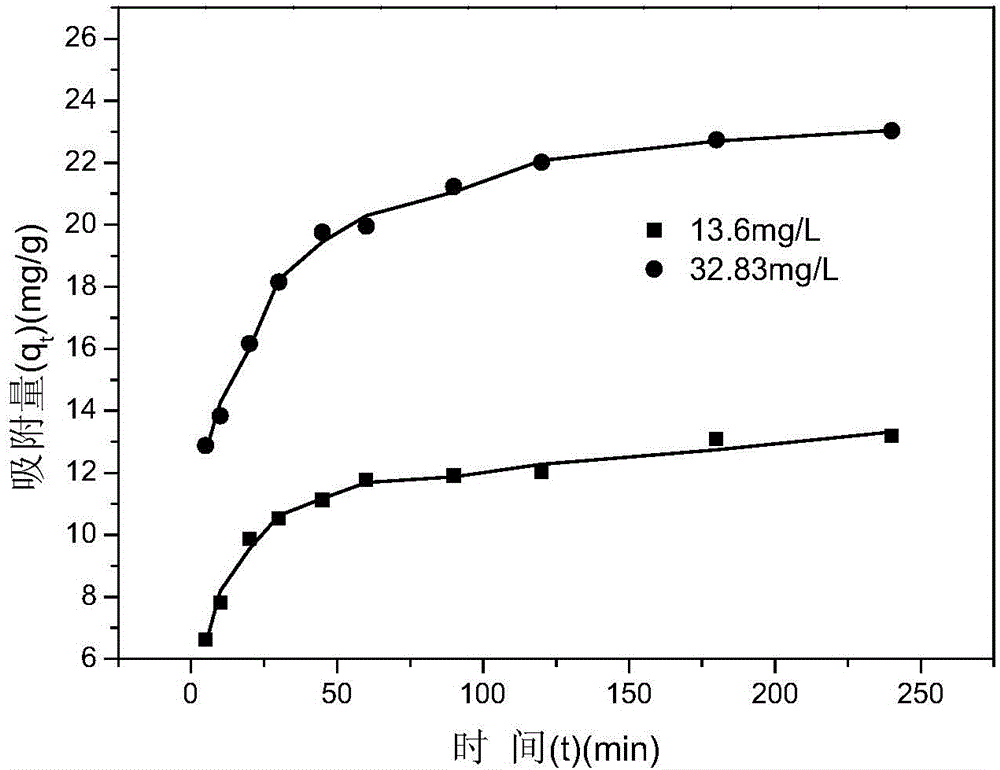

[0032] Example 3 Preparation of bifunctional large-aperture mesoporous silica

[0033] The triamino-modified mesoporous silica (2.2 g) prepared in step 2 was added to 60 mL (0.1 mol / L) disodium ethylenediaminetetraacetic acid (disodium EDTA) aqueous solution, and stirred at room temperature for 24 h. Suction filtration, washing several times with ultrapure water, and drying to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com