Preparation of nano magnesium hydrate

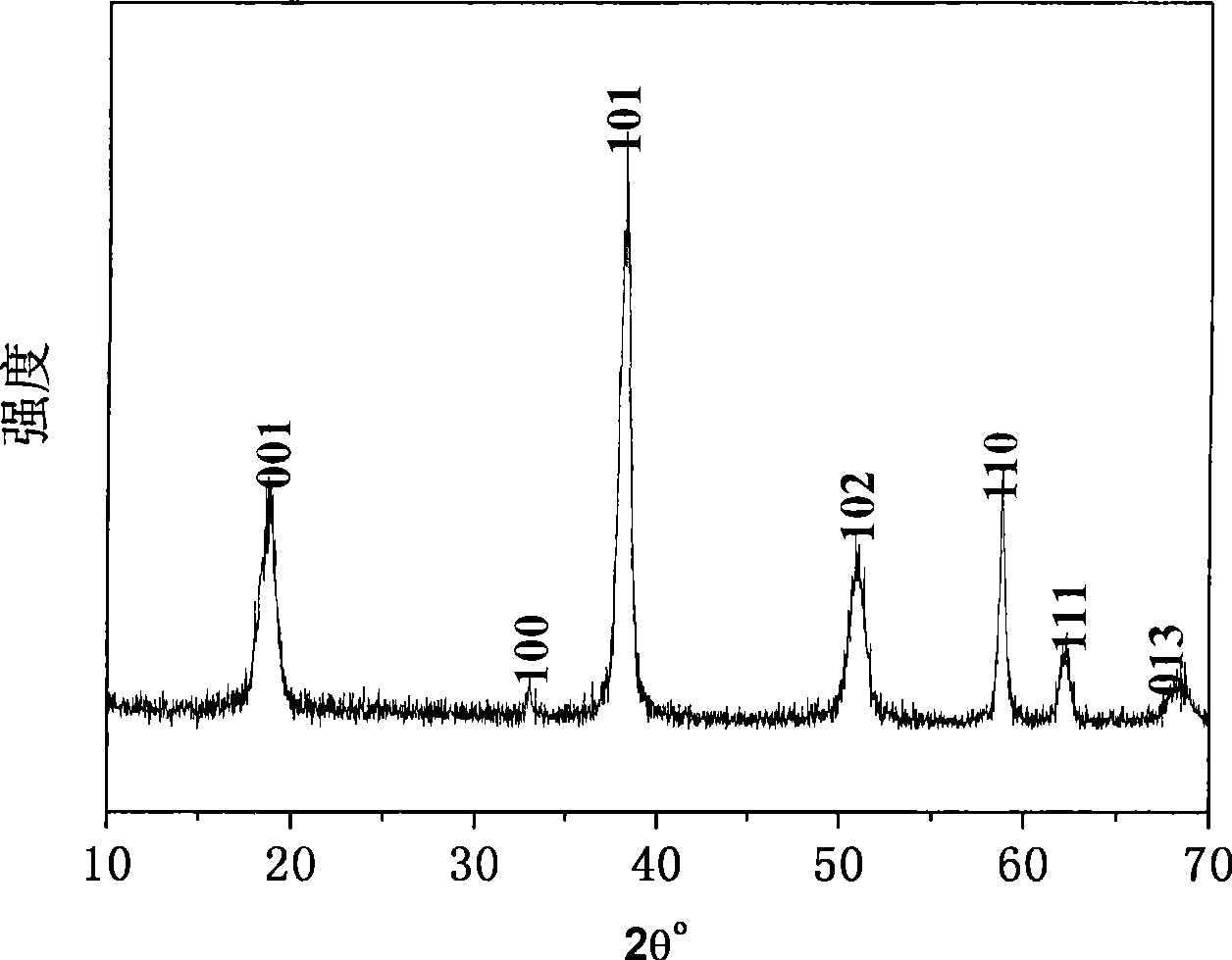

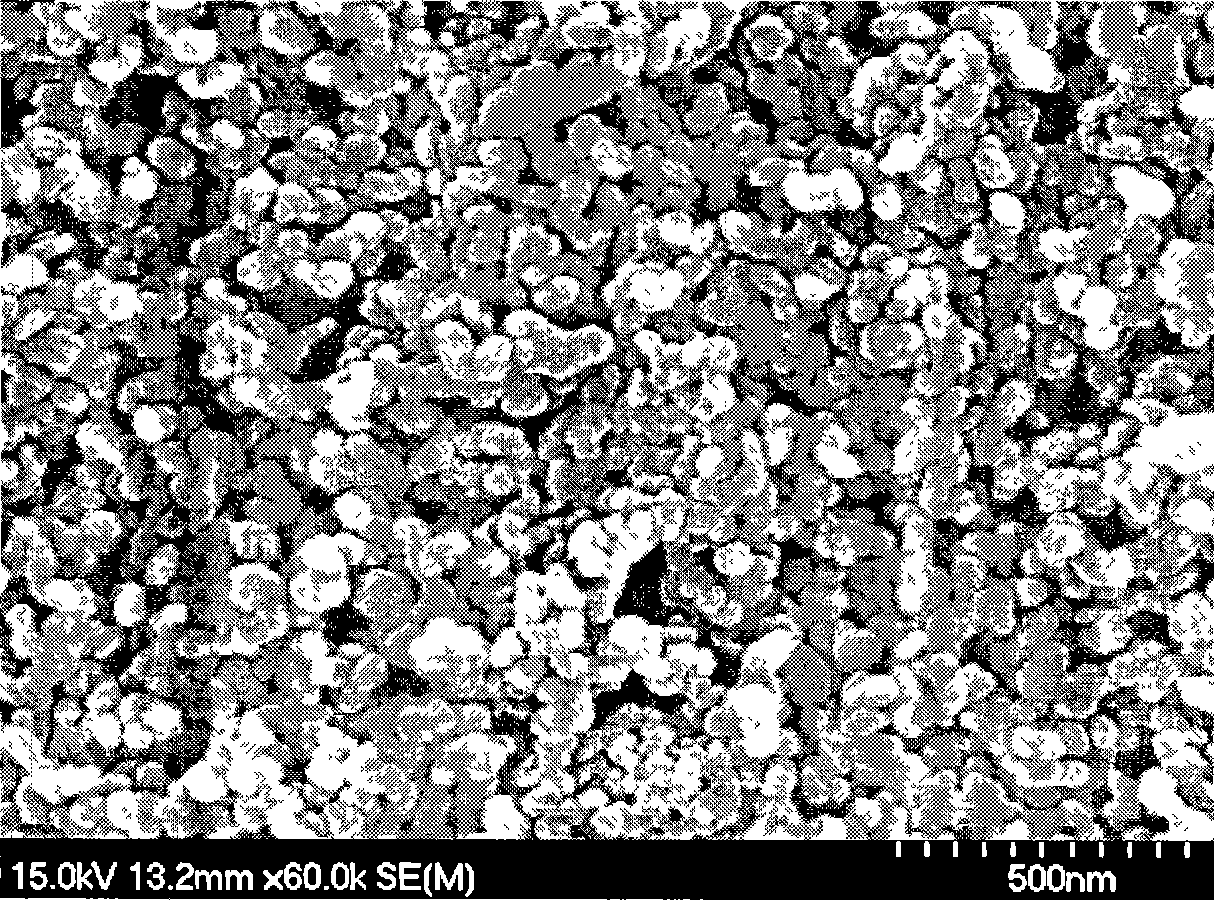

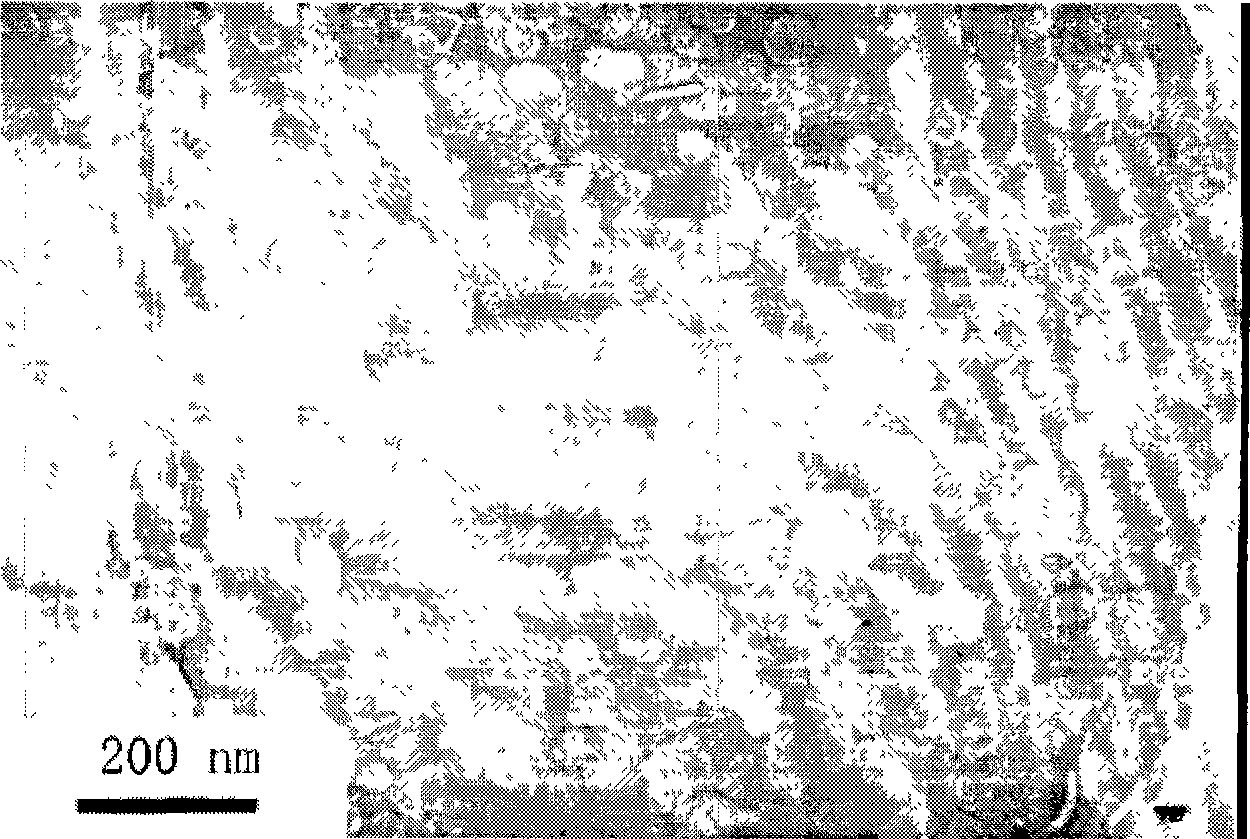

A technology of nano-magnesium hydroxide and magnesium hydroxide, which is applied in the preparation of ultrasonic-assisted synthesis of nano-powder and the field of ultrasonic-assisted synthesis of nano-magnesium hydroxide, can solve the problems of difficult operation, long reaction time, long ultrasonic time, etc. The particle size distribution is uniform, the further growth is inhibited, and the product dispersibility is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 28.5g MgCl 2 ·6H 2 O and 0.86g of polyethylene glycol were dissolved in deionized water, and stirred to form a 100ml magnesium salt solution; in addition, 11.2g of NaOH was also dissolved in deionized water to form a 100ml lye solution. First add the magnesium salt solution into a 250ml three-necked flask, start the stirrer, and control the rotation speed to 600rpm; at the same time, turn on the ultrasonic wave, control the ultrasonic frequency to 59KHz, and the ultrasonic power to 100W. Then slowly drop an aqueous sodium hydroxide solution into the three-necked flask, react at 25° C. to obtain a magnesium hydroxide suspension, and then ultrasonically age the magnesium hydroxide suspension for 10 minutes. The suspension was filtered, washed with deionized water until no chloride ions were detected, and the filter cake was dried at 110° C. for 4 hours to obtain flaky magnesium hydroxide powder with an average particle size of 70 nm.

Embodiment 2

[0020] 28.5g MgCl 2 ·6H 2 O and 0.57g of polyvinyl alcohol were dissolved in deionized water and stirred to form a 100ml magnesium salt solution; in addition, 15.7g of KOH was also dissolved in deionized water to form a 100ml lye solution. First add the magnesium salt solution into a 250ml three-neck flask, start the stirrer, and control the rotation speed at 500rpm; at the same time, turn on the ultrasonic wave, control the ultrasonic frequency to 33KHz, and the ultrasonic power to 100W. Then slowly drop an aqueous sodium hydroxide solution into the three-necked flask, react at 25° C. to obtain a magnesium hydroxide suspension, and then ultrasonically age the magnesium hydroxide suspension for 15 minutes. The suspension was filtered, washed with deionized water until no chloride ions were detected, and the filter cake was dried at 120° C. for 3 hours to obtain flaky magnesium hydroxide powder with an average particle size of 90 nm.

Embodiment 3

[0022] 28.5g MgCl 2 ·6H 2 O and 1.14g of zinc stearate were dissolved in deionized water and stirred to form 100ml of magnesium salt solution; 44.0ml of ammonia water was also dissolved in deionized water to form 100ml of lye. First add the magnesium salt solution into a 250ml three-necked flask, start the stirrer, and control the rotation speed to 700rpm; at the same time, turn on the ultrasonic wave, control the ultrasonic frequency to 80KHz, and the ultrasonic power to 100W. Then slowly drop an aqueous sodium hydroxide solution into the three-necked flask, react at 25° C. to obtain a magnesium hydroxide suspension, and then ultrasonically age the magnesium hydroxide suspension for 8 minutes. The suspension was filtered, washed with deionized water until no chloride ions were detected, and the filter cake was dried at 100°C for 6 hours to obtain flaky magnesium hydroxide powder with an average particle size of 50 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com