Silicon oxide-chitosan composite aerogel and preparation method thereof

A composite aerogel and composite gel technology, applied in the field of silica-chitosan composite aerogel and its preparation, to achieve the effect of low price, simple steps and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

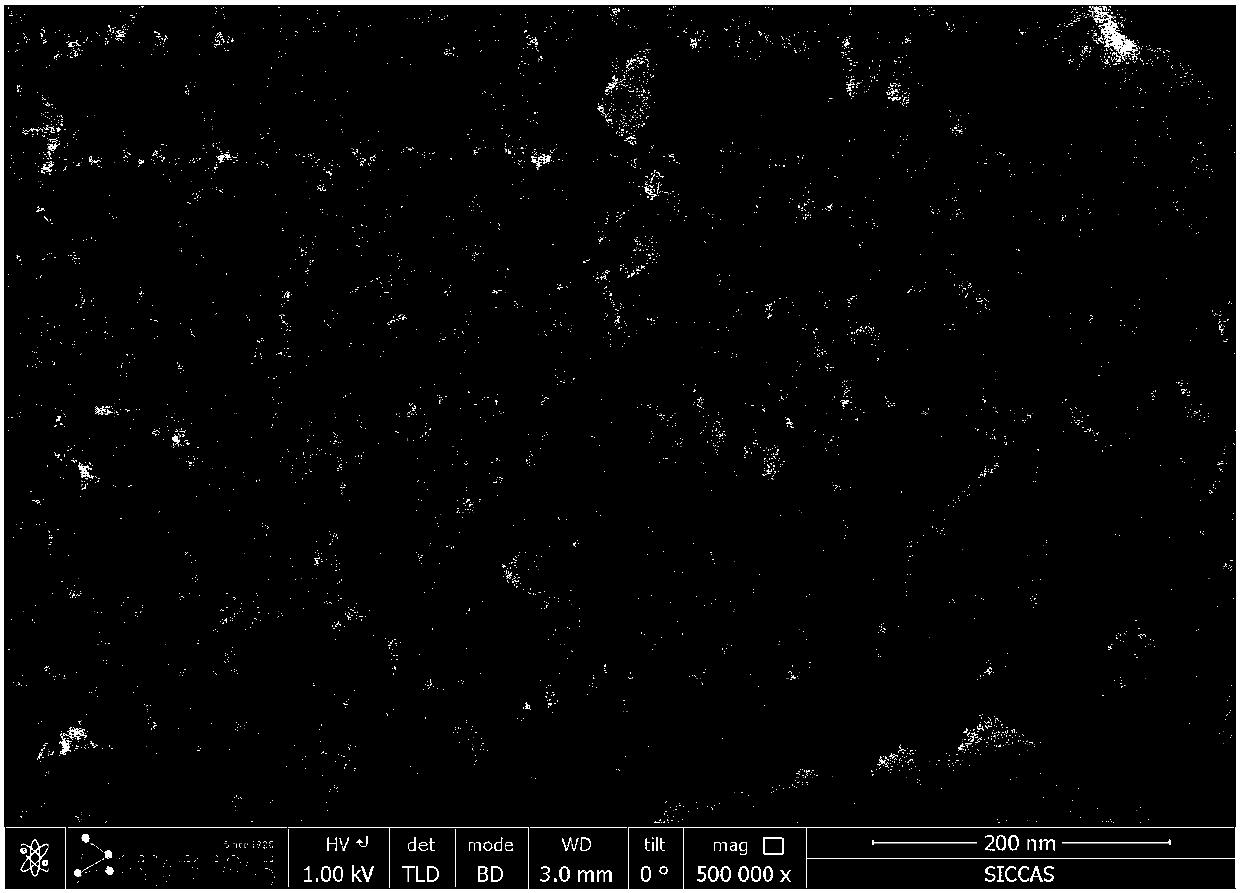

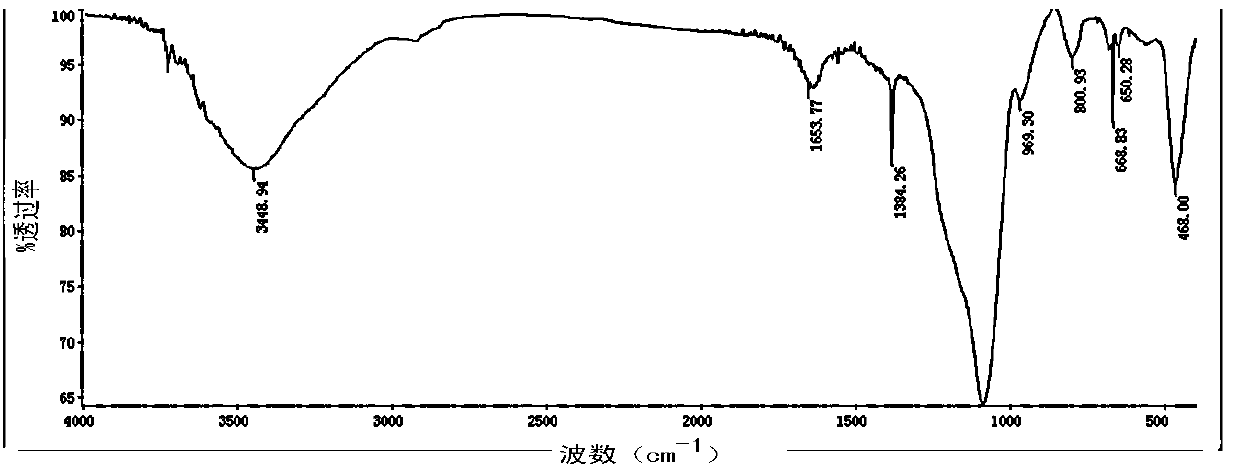

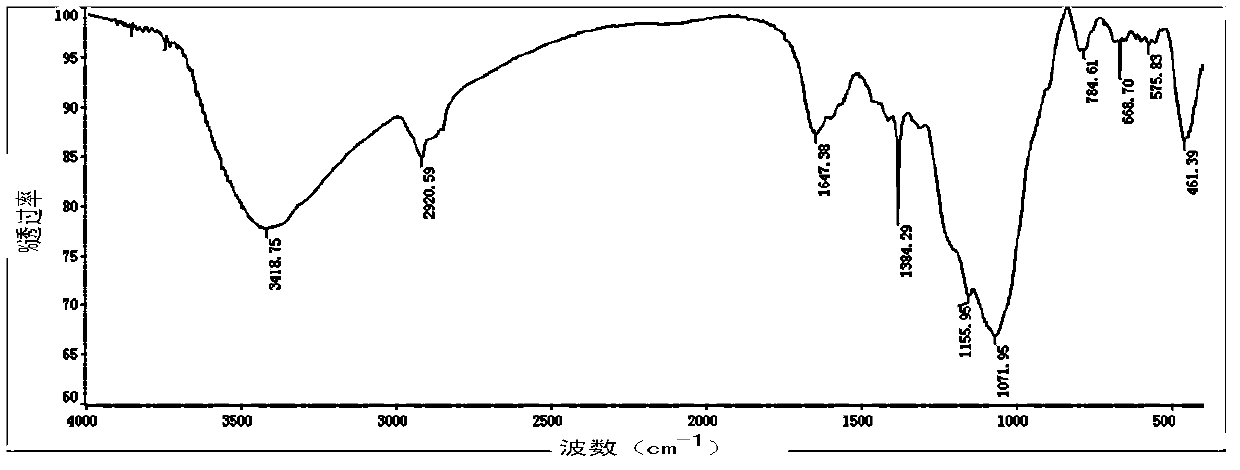

[0032] The invention relates to a silicon oxide-chitosan composite airgel and a preparation method thereof. The silica-chitosan composite airgel prepared by the present invention has a three-dimensional porous network structure, and the BET specific surface area is 300-1000m 2 / g, the tap density is 0.1-1.0g / cm 3 , and its components are as follows: the mass fraction of chitosan is 9%-65%, the mass fraction of chitosan cross-linking agent is 1%-5%, and the mass fraction of silicon oxide is 30%-90%.

[0033] The method of the present invention comprises the following steps: (1) prepare silica-chitosan composite sol; (2) prepare silica-chitosan gel; (3) polar organic compound of silica-chitosan gel Solvent replacement; (4) non-polar solvent replacement and surface chemical modification of silica-chitosan gel; (5) normal pressure drying of silica-chitosan gel and silica-chitosan composite gas Obtaining the gel. The composite airgel prepared by the invention has good acid and a...

Embodiment 1

[0052] 1) Select 10 milliliters of industrial water glass with a modulus of 3.0, mix it with 40 milliliters of deionized water, and stir evenly to obtain a diluted water glass solution (A). Mix strong acidic ion exchange resin with a volume ratio of 1:1 and dilute water glass, stir for 10 minutes, and filter to obtain the clear liquid, that is, the silicic acid solution (B) with a pH value of 2-3. Dissolve 0.5 g of chitosan powder in 50 ml of 0.1 mol / L acetic acid solution to prepare chitosan solution (C). Pour 50 milliliters of silicic acid solution (B) into 50 milliliters of chitosan solution (C), and stir for 20 min to obtain a mixed solution (D) of chitosan and silicic acid solution;

[0053] 2) Use ammonia water to adjust the pH value of the mixed solution (D) to about 6, add 100 microliters of glutaraldehyde with a mass concentration of 25%, stir for 20 minutes, and react at 60°C for 1 hour to obtain silica-chitosan composite water Gel (E);

[0054] 3) The silica-chito...

Embodiment 2

[0060] 1) Select 10 milliliters of industrial water glass with a modulus of 3.0, mix it with 40 milliliters of deionized water, and stir evenly to obtain a diluted water glass solution (A). Mix strong acidic ion exchange resin with a volume ratio of 1:1 and dilute water glass, stir for 10 minutes, and filter to obtain the clear liquid, that is, the silicic acid solution (B) with a pH value of 2-3. Dissolve 1 g of chitosan powder in 50 milliliters of 0.1 mol / L acetic acid solution to prepare chitosan solution (C). Pour 50 milliliters of silicic acid solution (B) into 50 milliliters of chitosan solution (C), and stir for 20 min to obtain a mixed solution (D) of chitosan and silicic acid solution;

[0061] 2) Use hexamethylenetetramine to adjust the pH value of the mixed solution (D) to about 6, add 200 microliters of glutaraldehyde with a mass concentration of 25%, stir for 20 minutes, and react at 60° C. for 1 hour to obtain silicon oxide- Chitosan composite hydrogel (E);

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com