Preparation method of nitrogen doped graphene/ metal oxide nanometer composite material

A technology of nitrogen-doped graphene and nanocomposite materials, which is applied in the direction of titanium oxide/hydroxide, oxides of ferrous iron, chemical instruments and methods, etc., can solve the problems of complex preparation process, large pollution, high cost, etc. Achieve the effect of simple process, less equipment investment and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

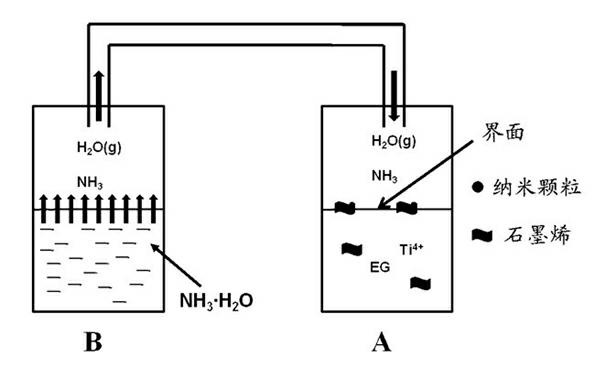

[0029] Weigh 7.7 g of titanium chloride (TiCl 4 ) and 1 g of graphene were poured into a container filled with ethanol and ultrasonically dispersed for 15 h to obtain a mixture. Then this mixed solution is poured in airtight container A, communicates with another airtight container B that ammoniacal liquor is filled, at 130 o C, the volatilized ammonia gas reacted with titanium chloride at the gas-liquid interface for 6 h, cooled, centrifuged, washed, dried, and finally put the dried powder into a tube furnace, and passed ammonia gas for 800 o C, 6 h, lowered to room temperature to obtain nitrogen-doped graphene / TiO 2 The yield of the nanocomposite material was 94.62%, and the percentage of nitrogen-doped graphene in the obtained composite material was 19.49 wt%.

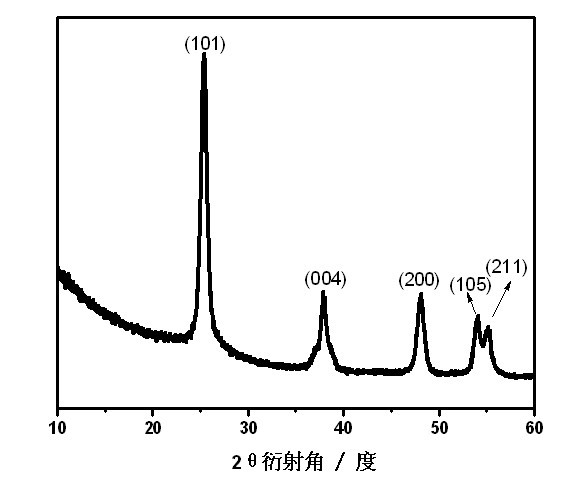

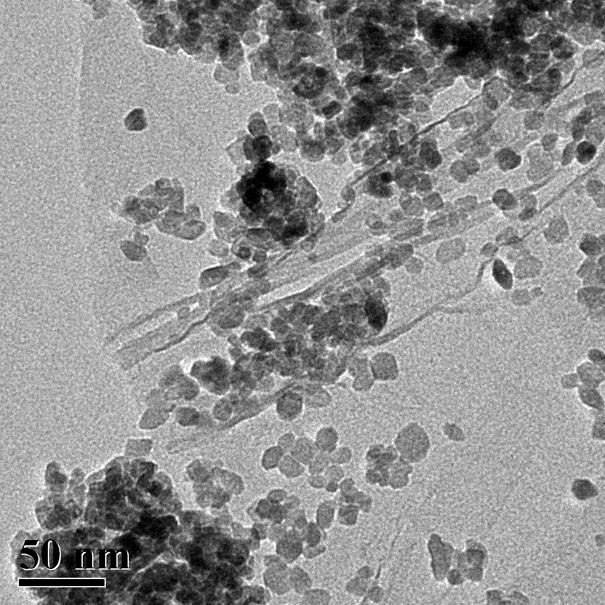

[0030] The X-ray diffraction pattern of gained composite material and transmission electron microscope are respectively as follows figure 2 and image 3 As shown, it can be seen that the resulting composite is ...

Embodiment 2

[0033] Weigh 20 g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) and 1 g of graphene were poured into a container filled with N, N-dimethylformamide, and ultrasonically dispersed for 6 h to obtain a mixed solution. Then pour the mixed solution into the airtight container A and communicate with another airtight container B containing ammonia water. At 150°C, the volatilized ammonia gas reacts with bismuth nitrate at the gas-liquid interface for 3 hours, cools, centrifuges, Wash, dry, and finally put the dried powder into a tube furnace, pass a mixture of ammonia and argon at 800 °C for 2 h, and cool down to room temperature to obtain nitrogen-doped graphene / Bi 2 o 3 Nanocomposite material, the yield rate is 91.69%, and the percentage of nitrogen-doped graphene in the obtained composite material is 4.03 wt%.

[0034] The X-ray diffraction patterns and transmission electron micrographs of the resulting composite material show that the resulting composite material is nitrogen-doped gra...

Embodiment 3

[0037] Weigh 7.7 g tin chloride (SnCl 4 ·5H 2 O) and 1 g of graphene, poured into a container filled with ethylene glycol, and ultrasonically dispersed for 8 h to obtain a mixed solution. Then pour the mixed solution into the airtight container A, and communicate with another airtight container B containing ammonia water. At 200°C, the volatilized ammonia gas reacts with tin chloride at the gas-liquid interface for 9 hours, then cools and centrifuges. , washing, drying, and finally put the dried powder into a tube furnace, pass ammonia gas at 700 °C for 5 h, and cool down to room temperature to obtain nitrogen-doped graphene / SnO 2 The yield of the nanocomposite material was 96.17%, and the percentage of nitrogen-doped graphene in the obtained composite material was 22.76 wt%.

[0038] The X-ray diffraction patterns and transmission electron microscope photos of the obtained composite material show that the obtained composite material is nitrogen-doped graphene / SnO 2nanocomp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com