A kind of bismuth oxycarbonate material of nano-micro scale plate and its preparation method

A bismuth oxycarbonate, nano-micron technology, applied in nanotechnology, chemical instruments and methods, bismuth compounds, etc., can solve the problems of poor dispersibility, high cost, expensive raw materials, etc., and achieve good dispersibility, low price, and purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

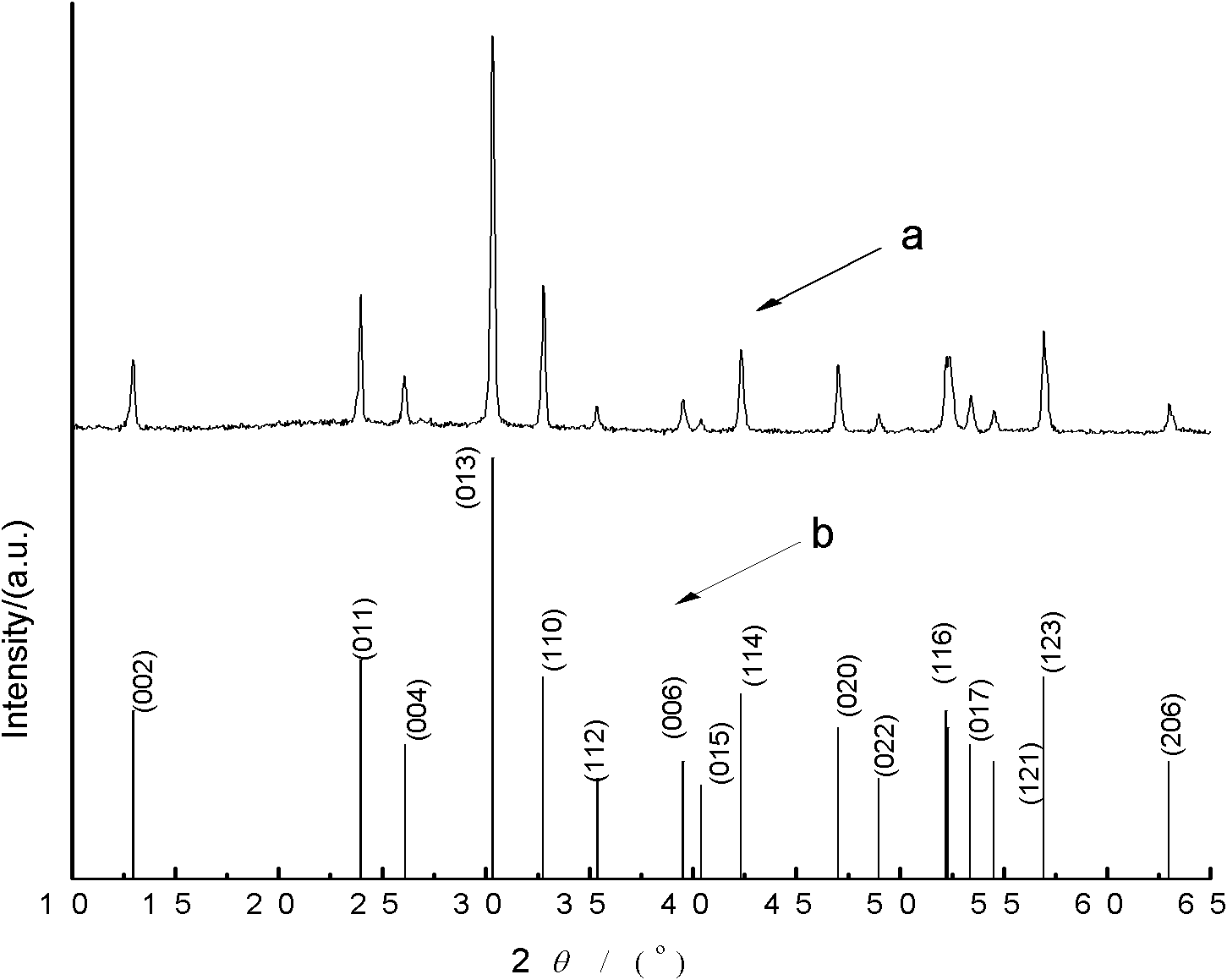

[0024] Dissolve 10.022 g of urea in 40 ml of double-distilled water, add 2.028 g of bismuth nitrate pentahydrate, and stir until completely dissolved to obtain a mixed solution. Transfer the mixed solution to a 100ml stainless steel autoclave lined with polytetrafluoroethylene (the pressure of the autoclave is above 3MPa, the same as in the following examples), and place the reactor in a constant temperature drying oven at a temperature of 180 Incubate at ℃ for 4 hours. After the reaction is completed, the reaction kettle is naturally cooled to room temperature, and the product is suction filtered to obtain a yellowish precipitate, which is washed several times with distilled water and dried at room temperature. After air drying, the carbonic acid obtained is weighed The mass of bismuth oxide is 0.9965 g, and the recovery rate of bismuth is tested according to the method of the Ministry of Health standard WS3-B-1553-93 (the same in the following examples), and the recovery rate ...

Embodiment 2

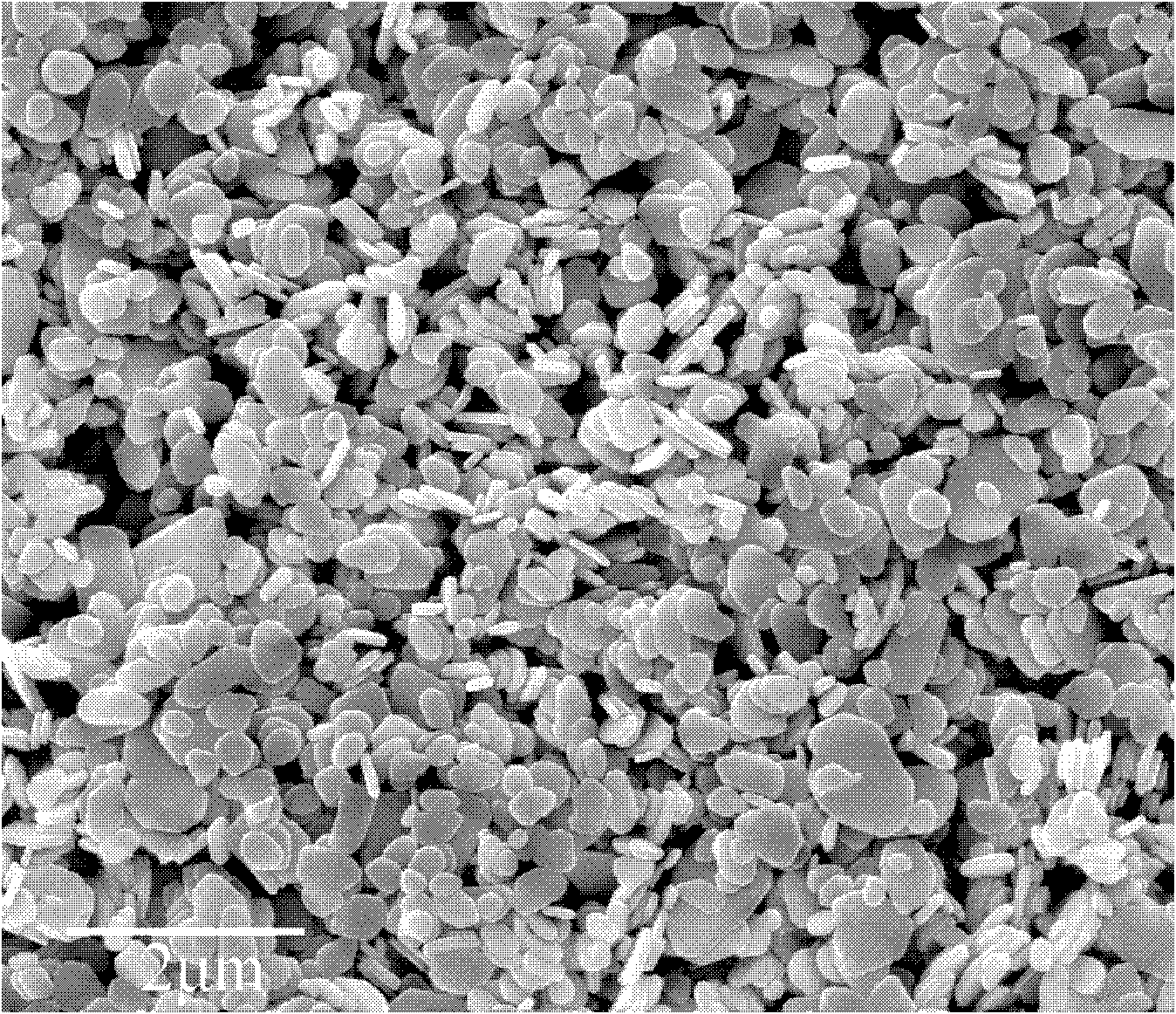

[0028] Dissolve 4.080g of urea in 40ml of double-distilled water, then add 2.038g of bismuth nitrate pentahydrate, stir until completely dissolved, transfer the mixed solution to a 100ml stainless steel autoclave lined with polytetrafluoroethylene. The reaction kettle was placed in a constant temperature drying box and kept at a temperature of 180°C for 2 hours. After the reaction was completed, the reaction kettle was naturally cooled to room temperature, and the product was suction filtered to obtain a yellowish precipitate, which was washed with distilled water several times. Place it to dry at room temperature. After air drying, the mass of the obtained bismuth oxycarbonate is 0.9937 g, and the recovery rate of bismuth is 91.34%. image 3 The SEM image of bismuth oxycarbonate in this example shows that the product has good dispersibility.

Embodiment 3

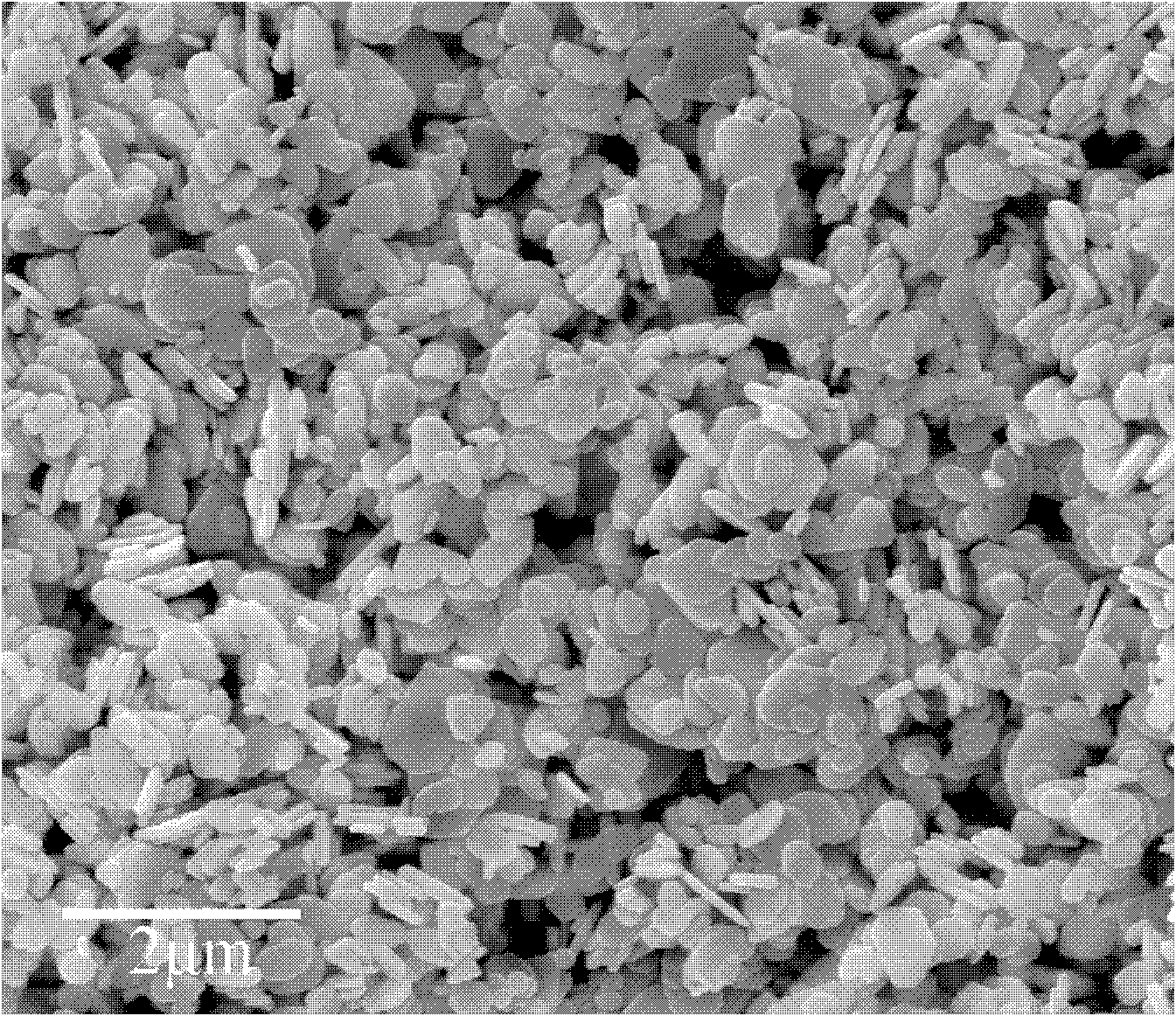

[0030] Dissolve 4.143g of urea in 30ml of double distilled water, then add 2.069g of bismuth nitrate pentahydrate, stir until completely dissolved, transfer the mixed solution to a 100ml stainless steel autoclave lined with polytetrafluoroethylene. The reaction kettle was kept at a temperature of 140°C for 4 hours. After the reaction was completed, the reaction kettle was naturally cooled to room temperature, and the product was suction filtered to obtain a yellowish precipitate, which was washed several times with distilled water and dried at room temperature. After air drying, the weight of the obtained bismuth oxycarbonate was weighed to be 0.9875 g, and the recovery rate of bismuth was 92.08%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com