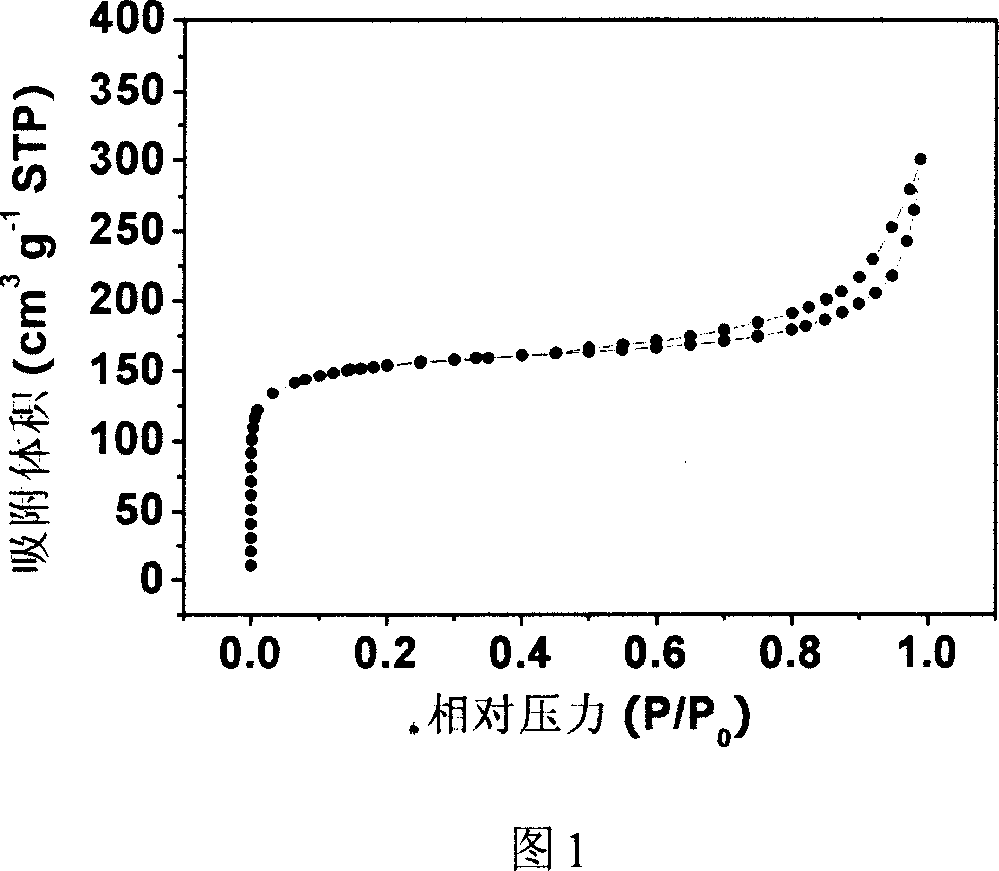

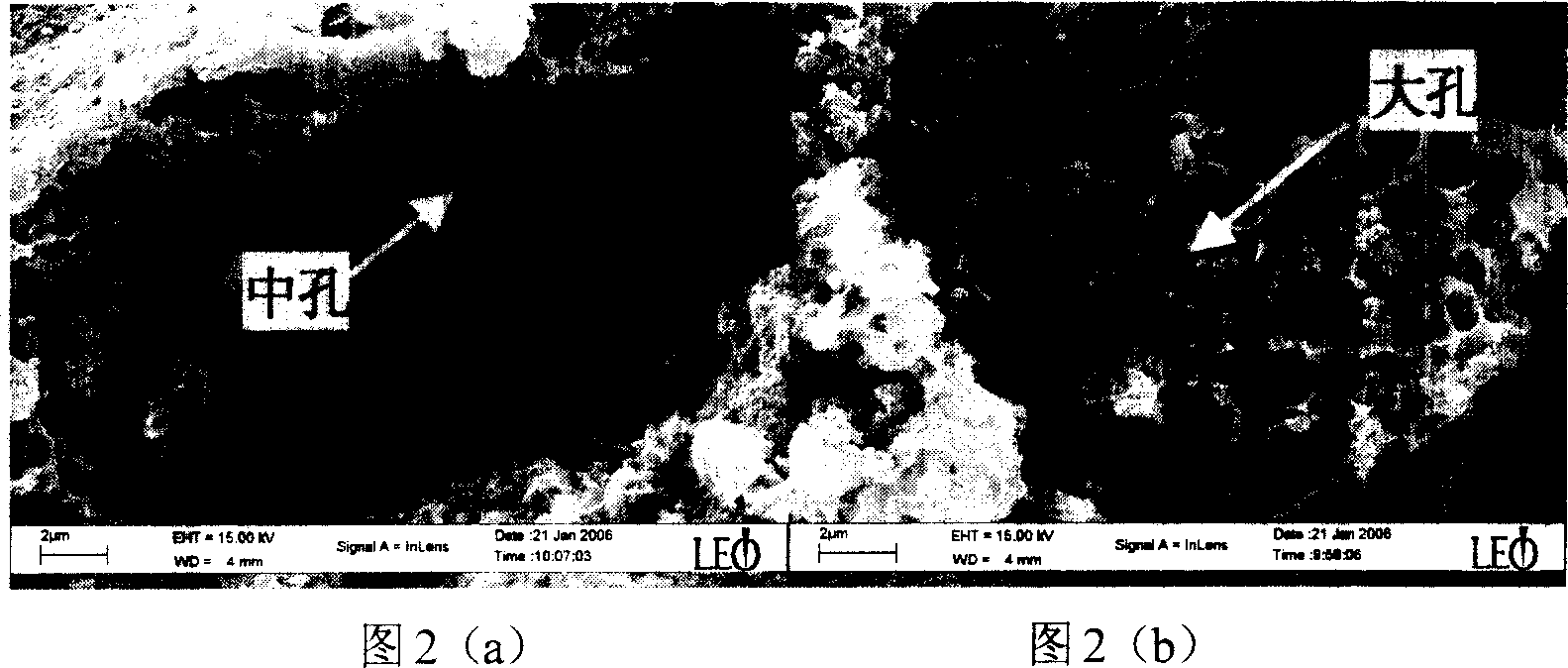

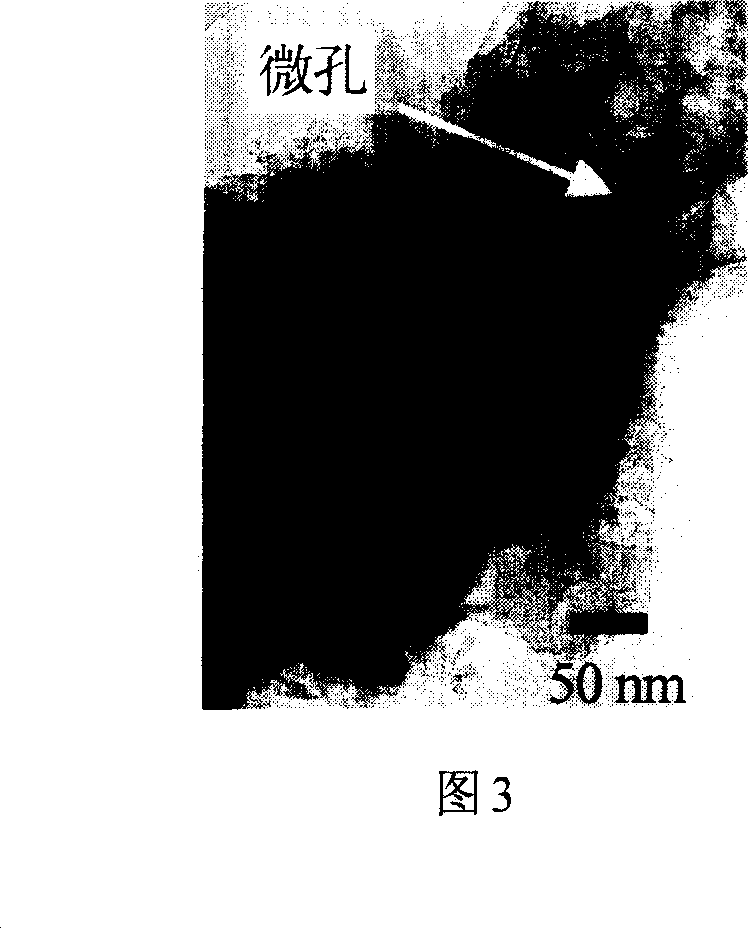

Layer combination controllable carbon material with nano pole of different scale, preparation method and application

A carbon material and nanopore technology, applied in the application field of electrochemical capacitor electrode materials, can solve the problems of low content, poor structure reproducibility, improvement of limiting performance and broadening of application range, etc., to achieve the effect of high-efficiency ion transport capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]Magnesium acetate and water are mixed and dissolved completely according to the weight ratio of 1:4 to form solution I. Sodium hydroxide, P123 and water are mixed and dissolved completely according to the weight ratio of 1:0.5:30 to form solution II, and then the above two solution systems are stirred and mixed at 20°C, and the weight ratio of magnesium acetate to sodium hydroxide is 1: 1. Under the action of a strong base (NaOH), the magnesium salt forms its hydroxide sol, and the ethanol solution of the alcohol-soluble phenolic resin is added (the weight ratio of the phenolic resin and ethanol is 1: 4), and the mixture of the phenolic resin and the magnesium salt is Adding the weight ratio is 1:1, after the phenolic resin is completely precipitated under the action of water, the solvent water and ethanol are evaporated and removed at 60°C (48 hours), and the phenolic resin / oxide composite material can be obtained, which is carbonized (600 °C, 6 hours, ammonia gas), was...

Embodiment 2

[0027] Nickel nitrate and water are mixed and dissolved completely according to the weight ratio of 1:5 to form solution I. Urea, CTAB and water are completely dissolved in a weight ratio of 1:1:20 to form solution II, and then the above two solution systems are stirred and mixed at 90°C. The weight ratio of nickel nitrate to urea is 1:3, and nickel nitrate is mixed in urea. Form its hydroxide sol under hydrolysis, add the ethanol solution of alcohol-soluble phenolic resin (the weight ratio of phenolic resin and ethanol is 1: 3), the adding weight ratio of phenolic resin and described nickel salt is 1: 1, treat phenolic resin After the resin is completely precipitated under the action of water, the solvent water and ethanol are evaporated and removed at 60°C (48 hours), and the phenolic resin / oxide composite material can be obtained, which is then carbonized (700°C, 6 hours, argon), and used Wash with hydrochloric acid to remove the template, mix the carbonized product and hyd...

Embodiment 3

[0031] Zinc chloride and water were mixed and dissolved completely in a weight ratio of 1:5 to form solution I. Sodium carbonate, Brij30 and water are mixed and dissolved completely according to weight ratio 1: 1: 30 to form solution II, then the above two solution systems are stirred and mixed at 10°C, the weight ratio of zinc chloride and sodium carbonate is 1: 3, Zinc chloride forms its carbonate / oxide composite sol in the double action of carbonate ion and water, adds the ethanol solution of alcohol-soluble phenolic resin (the weight ratio of phenolic resin and ethanol is 1: 6), phenolic resin and described zinc The weight ratio of the salt added is 1:2. After the phenolic resin is completely precipitated under the action of water, the solvent water and ethanol are evaporated and removed at 60°C (48 hours), and the phenolic resin / oxide composite material can be obtained and carbonized (800°C, 5 hours, argon), washed with hydrochloric acid to remove the template, mixed the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com