Silver-palladium alloy powder for conductive composition and preparation method of silver-palladium alloy powder

A technology of conductive composition and silver-palladium alloy, applied in the field of silver-palladium alloy powder for conductive composition and preparation thereof, can solve the problems of large pollution, uncontrollable degree of alloying, and inability to fully apply solderable conductive composition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

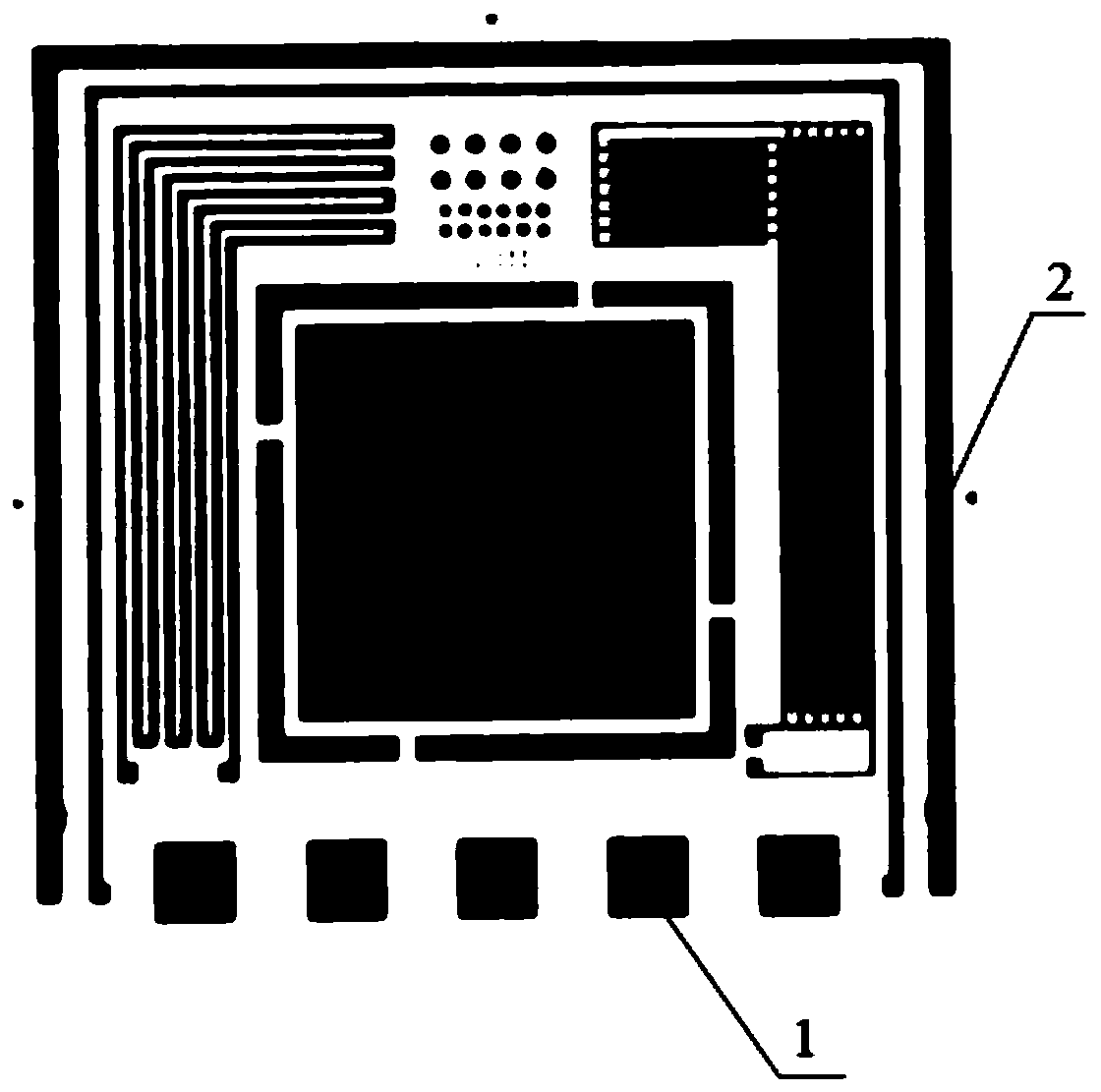

Image

Examples

preparation example Construction

[0033] The method for preparing the silver-palladium alloy powder of the present invention comprises making the mixture of the silver powder and the palladium powder undergo a solid-phase reaction. In this article, solid-phase reaction refers to the process of solid-solid reaction to generate new solid-phase products, which can also be called solid-phase alloy reaction and sintering reaction.

[0034] The solid-phase reaction of the present invention can be carried out using conventional equipment, for example, various temperature-controlled and pressure-controlled sintering equipment, such as a gas pressure sintering furnace, can be used.

[0035] In the present invention, the solid-phase reaction is carried out in a low temperature and high pressure environment. The temperature of the solid-phase reaction is preferably 250°C to 300°C, for example, within the range defined by any two temperature values selected from 250°C, 260°C, 270°C, 280°C, 290°C and 300°C as endpoints, ...

Embodiment 1

[0079] The silver-palladium alloy powder used in the present embodiment is prepared by the following method:

[0080] Silver powder with a particle size of 1.7μm to 2μm and a specific surface area of 5m 2 / g~8m 2 The palladium powder of / g is weighed according to the ratio of 99:1, mixed with a mixer, put into a ceramic crucible, put into a pressure sintering furnace, set the pressure in the furnace to 1MPa, the temperature of 250 ° C, and the holding time of 2 hours , the heating rate is 20°C / min.

[0081] Other raw materials used in this example are as follows:

[0082] Silver powder: particle size 1.7μm ~ 2μm;

[0083] Palladium powder: specific surface area is 5m 2 / g~8m 2 / g;

[0084] Glass powder: lead-free glass powder F-643;

[0085] Oxides: bismuth oxide and copper oxide;

[0086] Organic carrier: ethyl cellulose 5%, terpineol 95%.

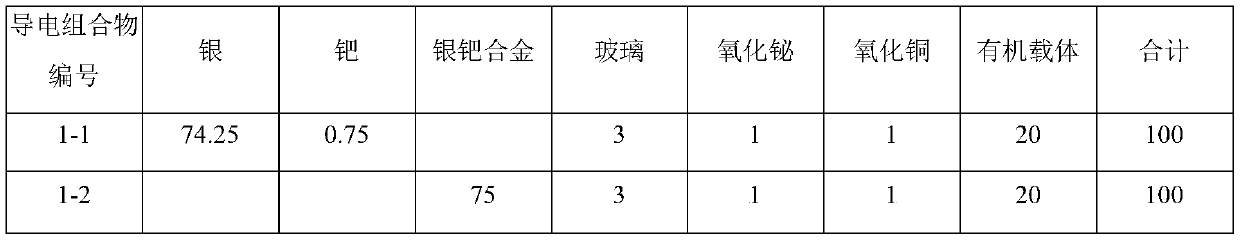

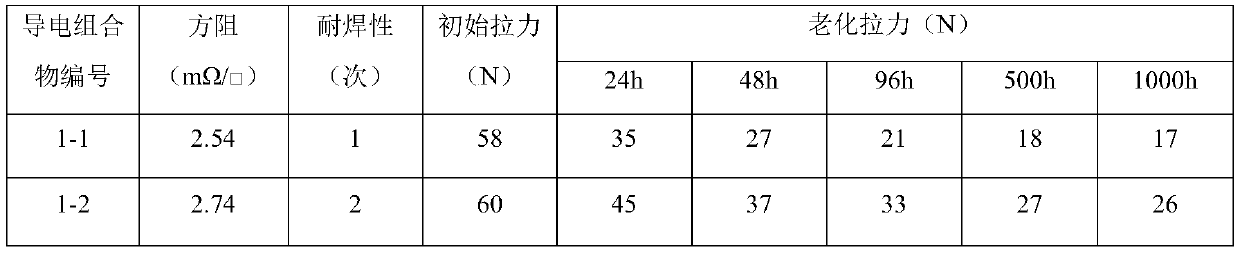

[0087] The material ratio and performance of the conductive composition of Example 1 are shown in Table 1 and Table 2, respec...

Embodiment 2

[0093] The silver-palladium alloy powder used in this example is prepared by the following method: silver powder with a particle size of 1.7 μm to 2 μm and a specific surface area of 5 m 2 / g~8m 2 The palladium powder of / g is weighed according to the ratio of 97:3, mixed with a mixer, put into a ceramic crucible, put into a pressure sintering furnace, set the pressure in the furnace to 1MPa, the temperature of 250 ° C, and the holding time of 3 hours , the heating rate is 20°C / min.

[0094] Other raw materials used in this example are as follows:

[0095] Silver powder: particle size 1.7μm ~ 2μm;

[0096] Palladium powder: specific surface area 5m 2 / g~8m 2 / g;

[0097] Glass powder: lead-free glass powder F-643;

[0098] Oxides: bismuth oxide and copper oxide;

[0099] Organic vehicle: ethyl cellulose: terpineol = 5:95.

[0100] The material ratio and performance of the conductive composition of Example 2 are shown in Table 3 and Table 4, respectively. The conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com