Method for producing civil dinitrotoluene

A dinitrotoluene and preparation technology technology, applied in the field of organic chemistry, can solve the problems of difficulty in controlling the isomerization ratio of dinitrotoluene products, increase the difficulty of waste acid treatment, and low product quality, and achieve maximum implementation value and Socioeconomic benefit, low production cost, and low nitrate content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

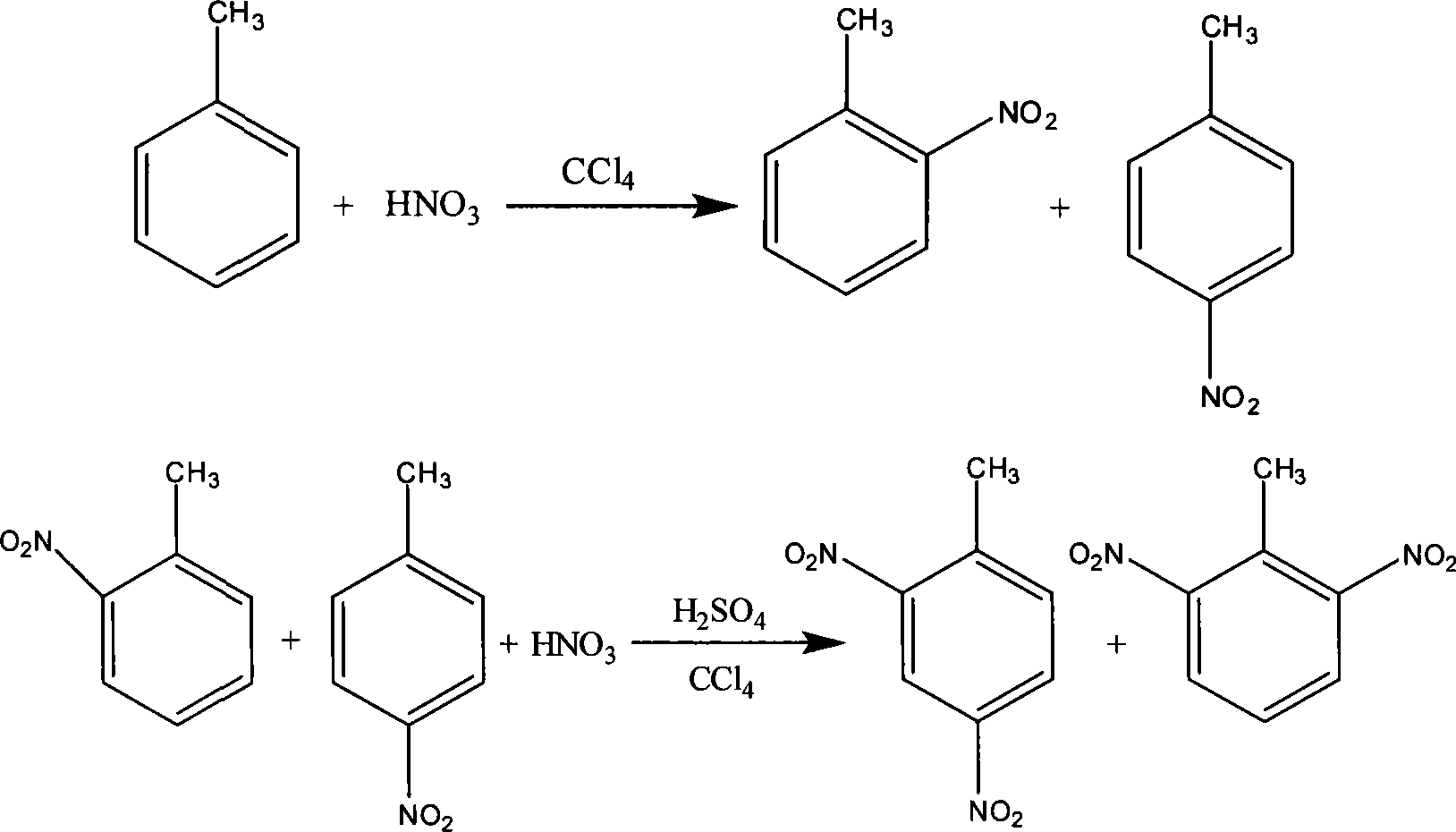

Method used

Image

Examples

Embodiment 1

[0021] One-stage nitration: add 4mL of carbon tetrachloride and 4mL of toluene in turn into a 100mL pear-shaped flask, raise the temperature to 50°C and slowly add 1.8mL of fuming nitric acid dropwise, and react for 20min.

[0022] Two-stage nitration: Slowly add 7mL of concentrated sulfuric acid (concentration: 98%) dropwise, add 2.4mL of fuming nitric acid dropwise after heating up to 65°C, and continue stirring for 60min.

[0023] Post-reaction treatment: after the reaction, let stand to separate the layers, then separate the organic phase while it is hot, distill off the solvent carbon tetrachloride to precipitate the product DNT; Chloromethane precipitates the product DNT. The combined product DNT was first washed with a sodium carbonate solution of about 2.5% DNT mass until the pH value was 7-8, then washed 2 to 3 times with an appropriate amount of water, pre-dried at room temperature for one day, then vacuum-dried to constant weight, weighed and Take an appropriate am...

Embodiment 2

[0025] One stage nitration: Add 8mL of carbon tetrachloride and 4mL of toluene into a 100mL pear-shaped flask in sequence, and slowly add 1.8mL of fuming nitric acid and 7mL of concentrated sulfuric acid (concentration 98.2%) dropwise after heating up to 30°C. React for 30 minutes.

[0026] Two-stage nitration: After heating up to 65°C, add 2.4mL of fuming nitric acid dropwise, and continue stirring for 60min.

[0027] Post-reaction treatment: After the reaction is over, let stand to separate layers, then separate the organic phase while it is hot, and distill the organic phase to remove the solvent carbon tetrachloride to precipitate the product DNT; The solvent chloroform precipitates the product DNT. The combined product DNT was first washed with a sodium carbonate solution of about 3% DNT mass until the pH value was 7-8, then washed 2 to 3 times with an appropriate amount of water, pre-dried at room temperature for one day, then vacuum-dried to constant weight, weighed an...

Embodiment 3

[0029] One-stage nitration: add 8mL of carbon tetrachloride and 4mL of toluene into a 100mL pear-shaped flask in sequence, raise the temperature to 50°C and slowly add 1.8mL of fuming nitric acid dropwise, and react for 10min.

[0030] Two-stage nitration: Slowly add 7mL of concentrated sulfuric acid (98.2%) dropwise, after heating up to 65°C, add 2.4mL of fuming nitric acid dropwise, and continue stirring for 90min.

[0031] Post-reaction treatment: after the reaction, let stand to separate the layers, then separate the organic phase while it is hot, distill off the solvent carbon tetrachloride to precipitate the product DNT; Chloromethane precipitates the product DNT. The combined product DNT was first washed with 3.5% sodium carbonate solution of DNT mass until the pH value was 7-8, then washed 2 to 3 times with an appropriate amount of water, pre-dried at room temperature for one day, then vacuum-dried to constant weight, weighed and taken Appropriate amount of DNT for ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com