Preparation method of white light OLED

A white light and ITO technology, applied in the field of white light OLED preparation, can solve the problems of poor repeatability, high cost, complex preparation process, etc., and achieve the effects of easy ratio, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

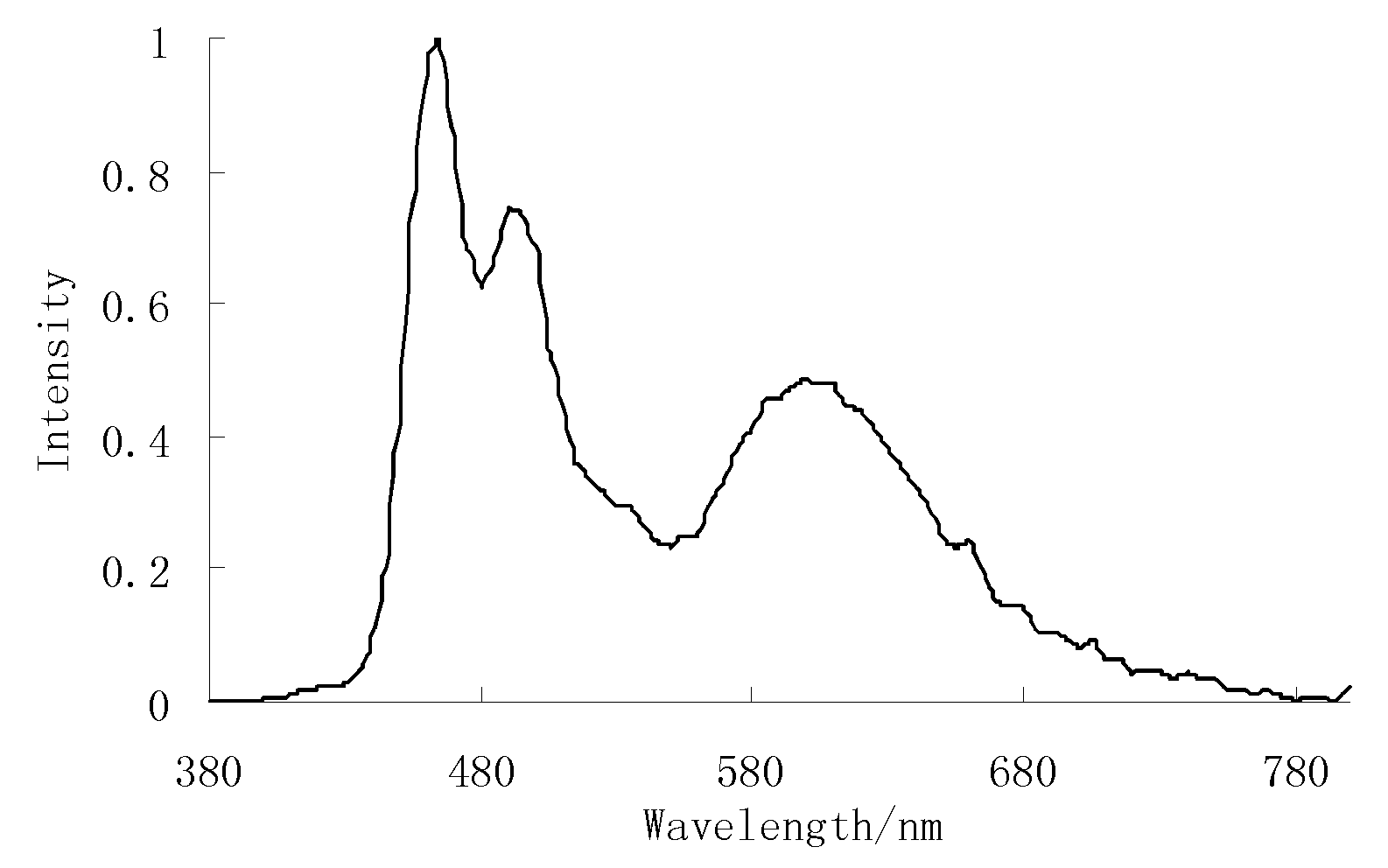

[0011] The preparation method of the white light OLED of the present invention includes the following steps: Step 1: Clean the ITO glass with trichlorethylene, acetone, absolute ethanol and distilled water in an ultrasonic cleaning machine, then transfer it to a drying box, and dry it at 150°C 30 minutes; step 2: transfer the ITO glass treated in step 1 to the coating machine, and bombard the surface of the ITO glass with oxygen plasma; step 3: take the material 2T-NATA for the electron blocking layer and NPB for the hole transport layer , ADN, TBPE and DCJTB materials for light-emitting layer, Alq materials for electron transport layer 3 Put into the coating machine together with the ITO glass that step 2 has processed with material liF and aluminum for the cathode layer, in a vacuum degree of 10 -4 Evaporate under the condition of Pa, that is, first heat the material for the electron blocking layer and the material for the hole transport layer to volatilize in order, thereby...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com