Ultra-fast preparation method of Bi nanoparticles and surface defects co-modified BiOCl nanosheets

A nanoparticle and nanosheet technology, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of simple deflagration reaction, strong repeatability, and broadened light absorption bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] At room temperature, 4.0 g of prepared BiOCl nanosheets and 0.1 g of sodium azide (NaN 3 ), a milky white suspension was obtained after magnetic stirring for 30 min. Slowly pour the suspension into a crucible filled with liquid nitrogen for rapid freezing, and freeze-dry to obtain BiOCl / NaN 3 mixture. Then it was placed in a closed high-temperature reaction kettle, filled with nitrogen protective gas, and heated by an electric heating wire to make NaN 3 A deflagration reaction occurred, and the product after the reaction was washed repeatedly with deionized water for more than 3 times, and dried in a vacuum oven at 60°C for 12 hours to obtain BiOCl nanosheets (BVB) co-modified with Bi nanoparticles and surface defects, which were named as BVB-1.

Embodiment 2

[0026] Add 4.0 g of BiOCl nanosheets and 0.2 of sodium azide (NaN 3 ), after magnetic stirring for 30 min, a milky white homogeneous suspension was obtained. Slowly pour the suspension into a crucible filled with liquid nitrogen for rapid freezing, and freeze-dry to obtain BiOCl / NaN 3 mixture. Then it was placed in a closed high-temperature reactor, and the other steps were the same as in Example 1 to obtain BiOCl nanosheets (BVB) co-modified with Bi nanoparticles and surface defects, which was named BVB-2.

Embodiment 3

[0028] At room temperature, 4.0 g of BiOCl nanosheets and 0.3 g of sodium azide (NaN 3 ), after magnetic stirring for 30 min, a milky white homogeneous suspension was obtained. Slowly pour the suspension into a crucible filled with liquid nitrogen for rapid freezing, and freeze-dry to obtain BiOCl / NaN3 mixture. Then it was placed in a closed high-temperature reactor, and the other steps were the same as in Example 1 to obtain BiOCl nanosheets (BVB) co-modified with Bi nanoparticles and surface defects, which was named BVB-3.

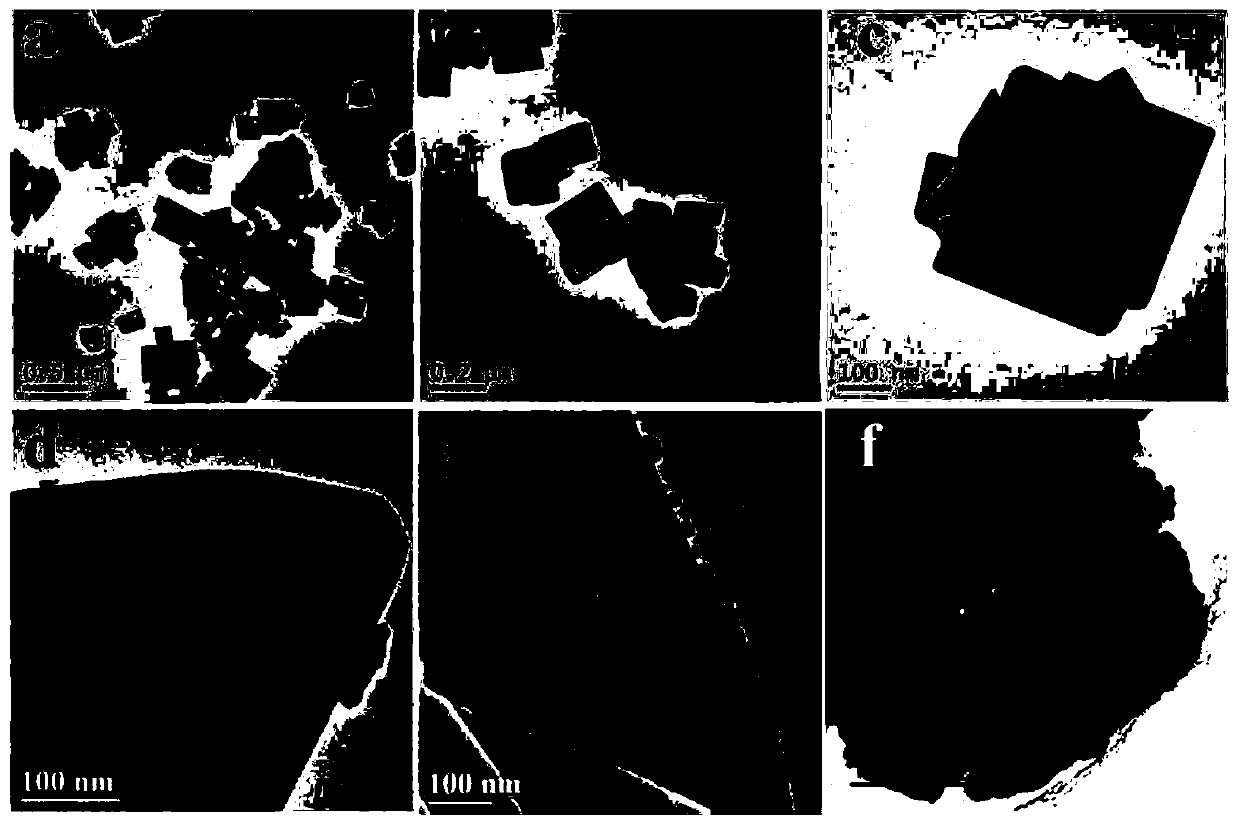

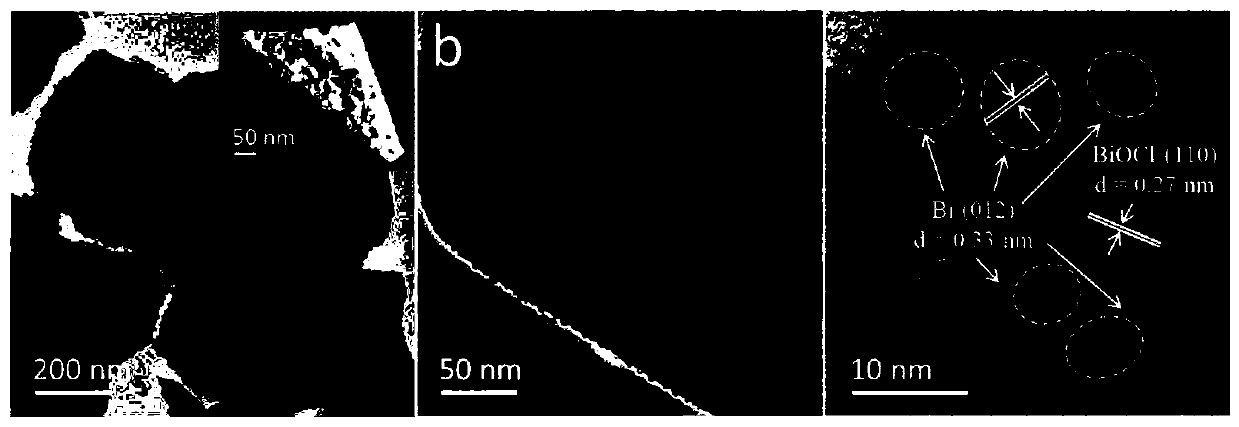

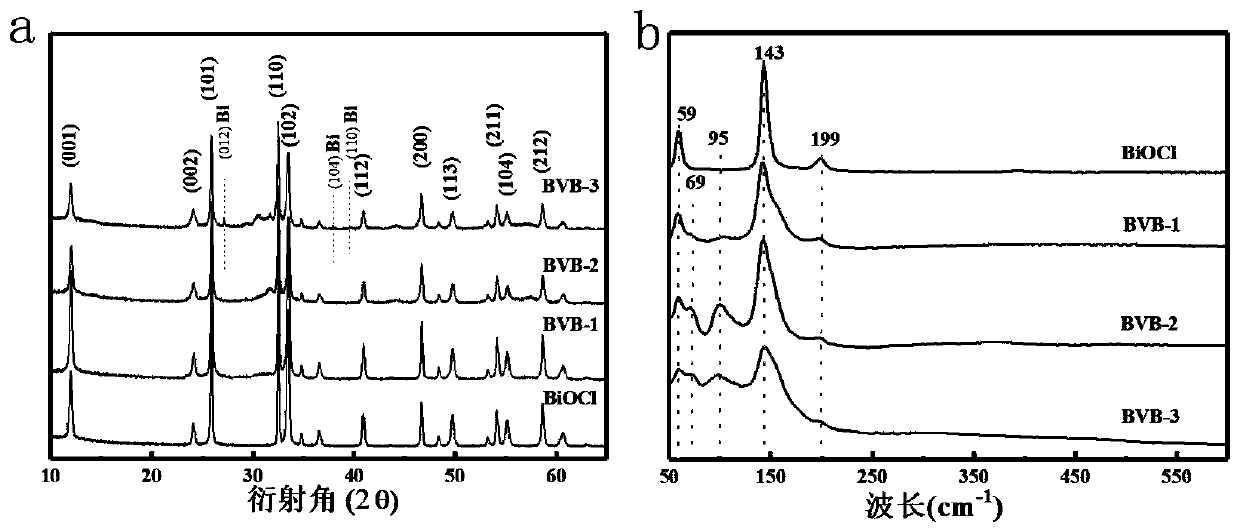

[0029] like figure 1 a-1c shows square BiOCl obtained by hydrothermal method. NaN 3 After deflagration treatment, such as figure 1 d–f, Compared with the smooth BiOCl nanosheets, BVB-1, BVB-2, and BVB-3 have a large number of micropits doped with Bi nanoparticles. like figure 2 It is shown that some small-sized rounded nanosheets appear in the sample in Example 2, and the high-resolution TEM image shows the lattice fringes of Bi nanoparticles with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com