Preparation method of modified natural wood material and application of modified natural wood material in sewage treatment

A kind of wood material and natural technology, applied in the field of preparation of modified natural wood materials, can solve the problems of low energy conversion utilization rate, environmental toxicity accumulation, secondary environmental pollution, etc. It is easy to achieve the preparation conditions, avoid secondary pollution, The effect of ensuring ecological security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the lignin removal solution in the embodiment of the present invention is as follows: dissolving 0.2 mol of sodium acetate in 150 mL of deionized water, dropwise adding glacial acetic acid to adjust the pH value to 4.6, then adding deionized water to 300 mL, and then adding 0.07 mol Sodium chlorite, stirring and dissolving to obtain a lignin removal solution.

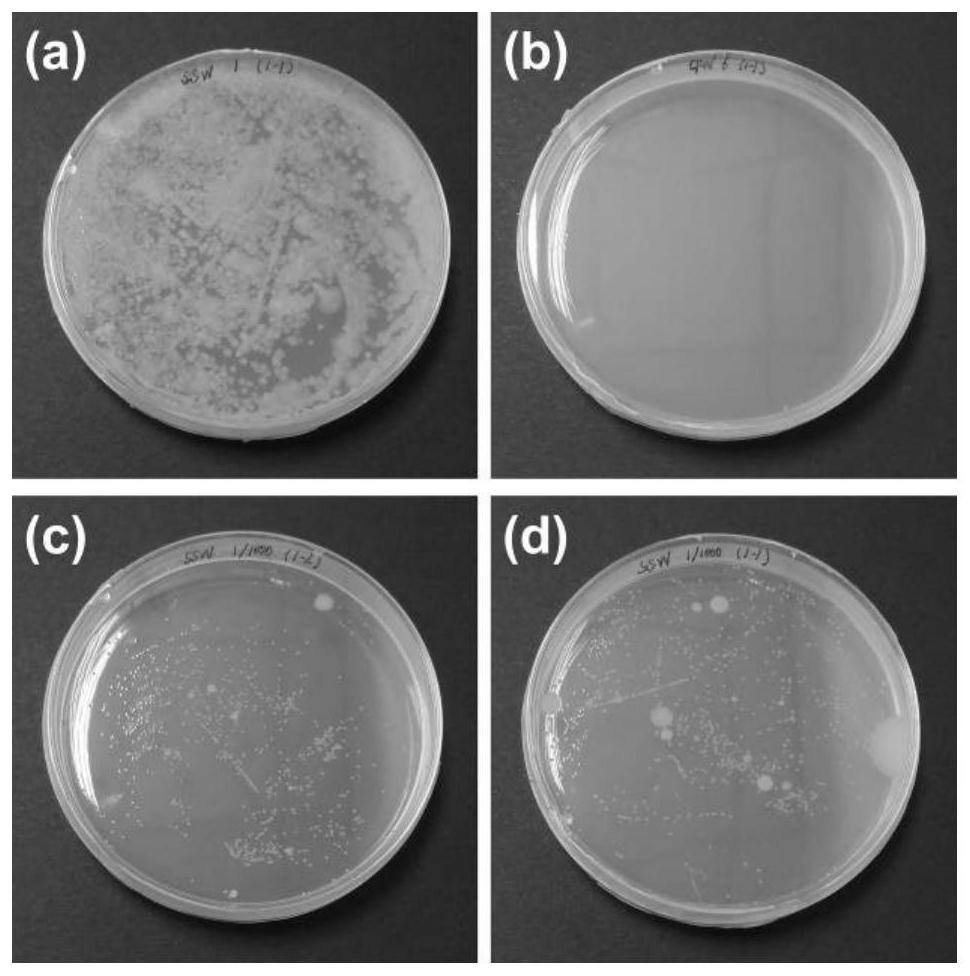

[0057] The components of the LB-agar solid medium in the test example of the present invention are as follows: each liter of the LB-agar medium contains 10.0 g of peptone, 5.0 g of yeast extract, 5.0 g of sodium chloride, 1.0 g of glucose, and 15.0 g of agar. Adjust pH to 7.0.

[0058] The components of the EMB-agar solid medium in the test example of the present invention are as follows: each liter of EMB-agar medium contains peptone 10.0g, lactose 10.0g, potassium dihydrogen phosphate 2.0g, agar 15.0g, eosin 0.4g, Blue 0.065g, the final adjusted pH value is 7.1.

[0059] The electron...

Embodiment 1

[0062] A preparation method of modified natural wood material, comprising the steps:

[0063] S1. Put the wood into the lignin removal solution, react in an oil bath at 100° C. for 8 hours, wash the wood with deionized water for 3 times, then put the wood into deionized water for 12 hours, and then immerse the wood in -20 After pre-freezing at ℃ for 24 hours, freeze-drying for 12 hours to obtain delignified wood;

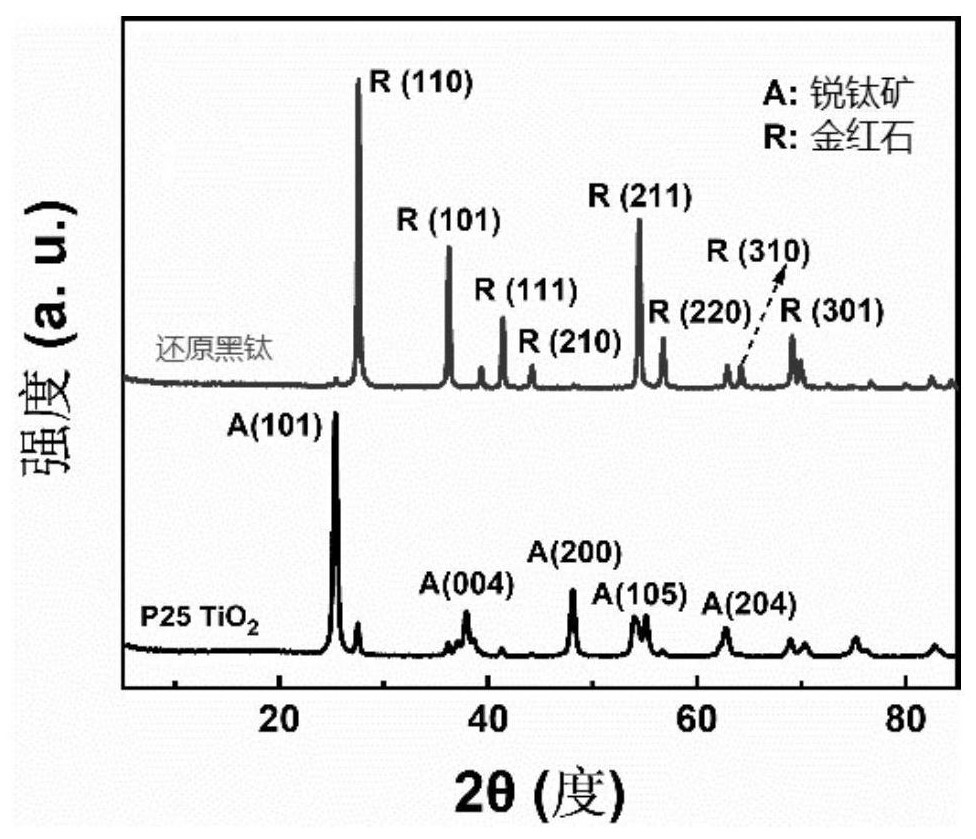

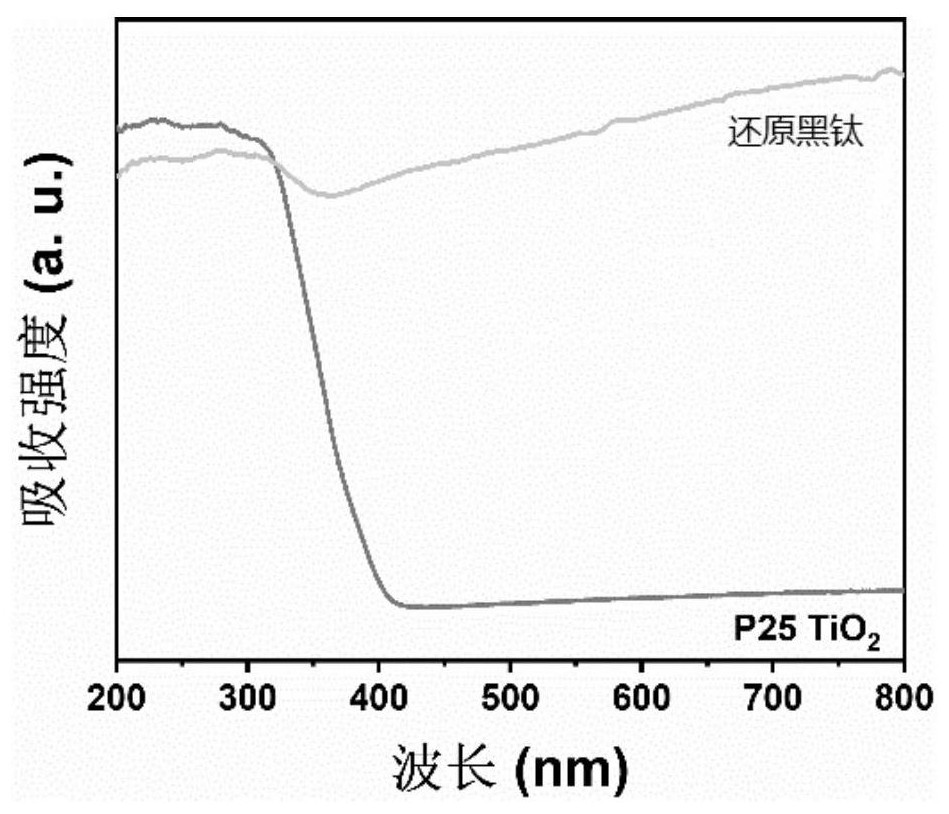

[0064] TiO with a molar ratio of 1.25:1 2 with NaBH 4 After mixing by low-speed ball milling, put it in a corundum crucible, heat it up to 350°C at a rate of 10°C / min under an argon atmosphere, cool down to room temperature after 1 h of reaction, and then wash it with deionized water and anhydrous ethanol for 3 times, respectively, in an oven at 60°C Drying to obtain reduced black titanium;

[0065] S2. Put 0.5g of the reduced black titanium into 5mL of absolute ethanol, ultrasonically disperse for 30min, then drop-coat and modify it on the delignified wood 3 tim...

Embodiment 2

[0069] A preparation method of modified natural wood material, comprising the steps:

[0070] S1. Put the wood into the lignin removal solution, react in an oil bath at 110° C. for 9 hours, wash the wood with deionized water for 3 times, then put the wood into deionized water for 12 hours, and then immerse the wood in -20 After pre-freezing at ℃ for 24 hours, freeze-drying for 12 hours to obtain delignified wood;

[0071] TiO with a molar ratio of 1.2:1 2 with NaBH 4 After mixing by low-speed ball milling, put it into a corundum crucible, heat it up to 340°C at a rate of 10°C / min under an argon atmosphere, cool it to room temperature after reacting for 1.2 hours, and then wash it with deionized water and absolute ethanol for 3 times respectively, and put it in an oven for 60 °C. ℃ drying to obtain reduced black titanium;

[0072] S2. put 0.5g of the reduced black titanium into 5mL of absolute ethanol, ultrasonically disperse for 20min, then drop-coat and modify the delignif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com