Graphene/bacterial cellulose composite material with gradient structure and preparation method thereof

A technology of bacterial cellulose and composite materials, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of single structure and inability to prepare graphene composite materials with gradient structure, and achieve simple preparation process , inhibition of graphene agglomeration, process safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

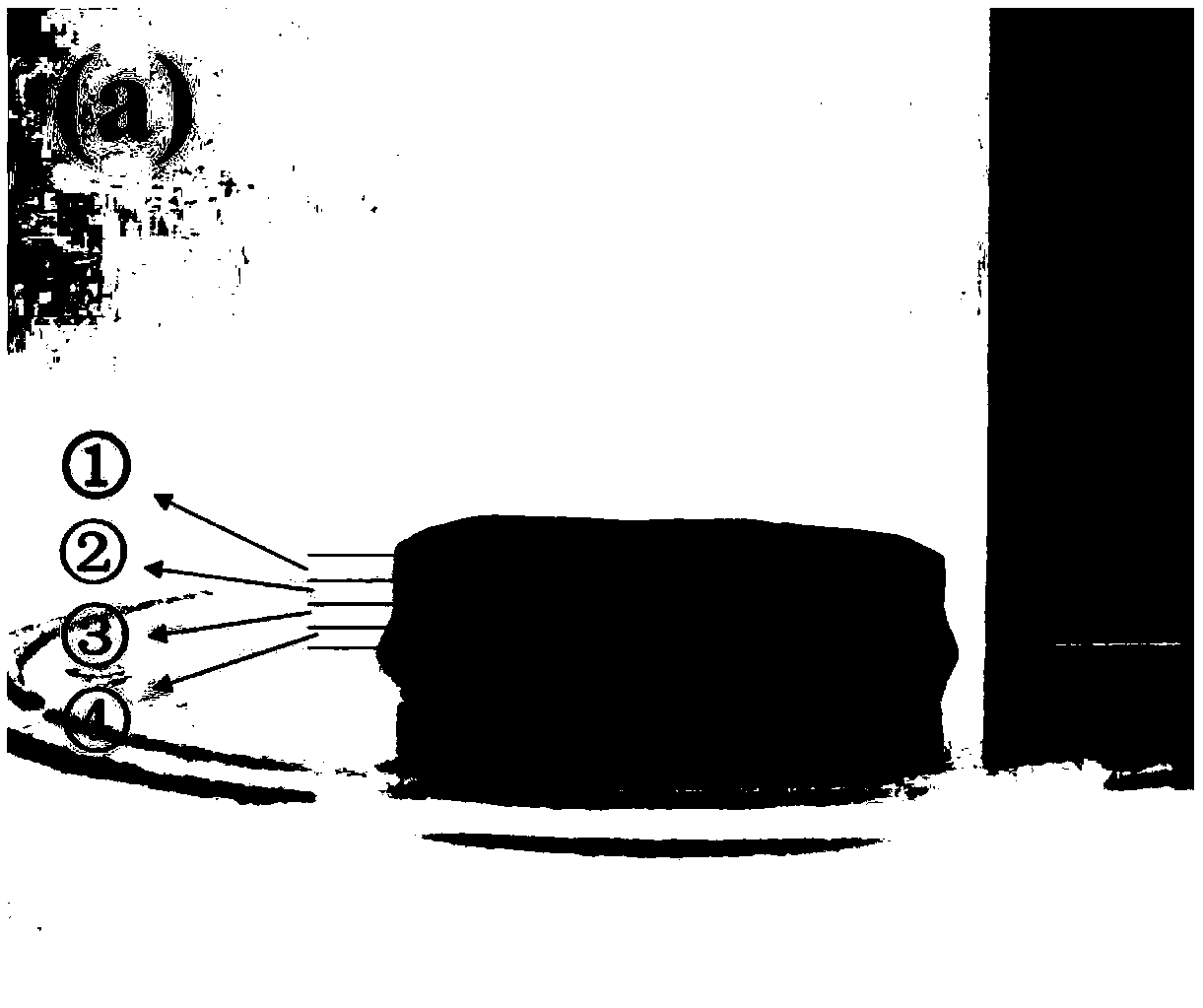

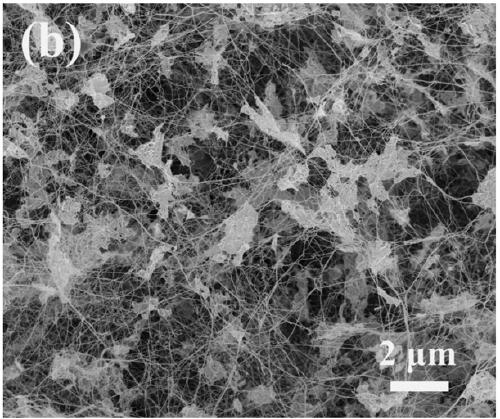

[0026] Example 1. Using graphene dispersion and bacterial cellulose as raw materials, a graphene / bacterial cellulose composite material with a gradient structure was prepared by using a membrane-liquid interface culture method. Specific steps are as follows:

[0027] Step 1. Preparation of medium: Add glucose (25g / L), yeast powder (7.5g / L), peptone (10g / L) and disodium hydrogen phosphate (10g / L) to a beaker containing 1000ml ultrapure water in sequence Stir until it is completely dissolved; use glacial acetic acid to adjust the pH value of the system to 4-5 to prepare a medium, put it in a sterilizer and sterilize it at 115°C and 0.1MPa for 30min to obtain the uninoculated Culture medium, spare;

[0028] Step 2, prepare three kinds of mixed media with different volume ratios:

[0029] Preparation of graphene dispersion: prepare a graphene dispersion with a mass volume concentration of 1 mg / ml in deionized water, sonicate for 15 minutes, and sterilize with ultraviolet light; ...

Embodiment 2

[0034] Example 2. Using graphene dispersion and bacterial cellulose as raw materials, a graphene / bacterial cellulose composite material with a gradient structure was prepared by using a membrane-liquid interface culture method. Specific steps are as follows:

[0035] Step 1, preparation culture medium: with embodiment 1;

[0036] Step 2, prepare three kinds of mixed culture mediums with different volume ratios: the preparation process is basically the same as in Example 1, the difference is only: the graphene dispersion and the culture medium volume ratios prepared in this Example 2 are respectively 1:7, 1: 3 and 2:1 (that is, the concentration of graphene is 0.125mg / ml, 0.25mg / ml, 0.67mg / ml respectively) three kinds of mixed medium; ultrasonic 15min, make the graphene flake particles evenly dispersed in in culture medium;

[0037] Step 3, preparation of basement membrane: same as Example 1;

[0038] Step 4, spray the above-mentioned three kinds of mixed culture mediums wit...

Embodiment 3

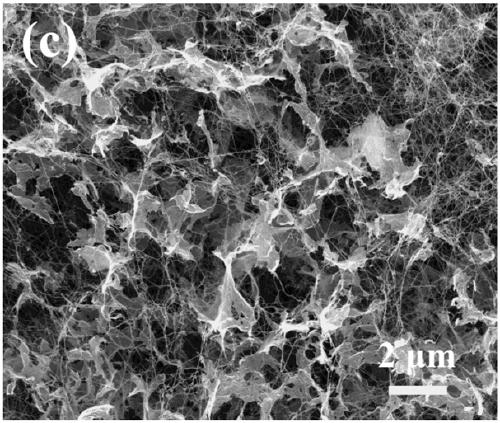

[0040] Example 3. Using graphene oxide dispersion liquid and bacterial cellulose as raw materials, a graphene oxide / bacterial cellulose composite material with a gradient structure was prepared by using a membrane-liquid interface culture method. Specific steps are as follows:

[0041] Step 1, preparation culture medium: with embodiment 1;

[0042] Step 2, prepare three kinds of mixed media with different volume ratios: the preparation process is basically the same as in Example 1, the difference is only: the graphene dispersion wherein is a graphene oxide dispersion whose mass volume concentration is 2mg / ml; this implementation In Example 3, the volume ratios of the graphene oxide dispersion to the culture medium were 1:39, 1:7, and 1:3 (that is, the graphene oxide concentrations were 0.05mg / ml, 0.25mg / ml, and 0.5mg / ml, respectively). Mixed medium with three ratios; ultrasonic for 15 minutes, so that the graphene oxide flake particles are evenly dispersed in the medium;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com