Thermoelasticity homogenizing method for three-dimensional random heterogeneous material under finite deformation

A heterogeneous, three-dimensional technology, applied in the direction of instrumentation, computing, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

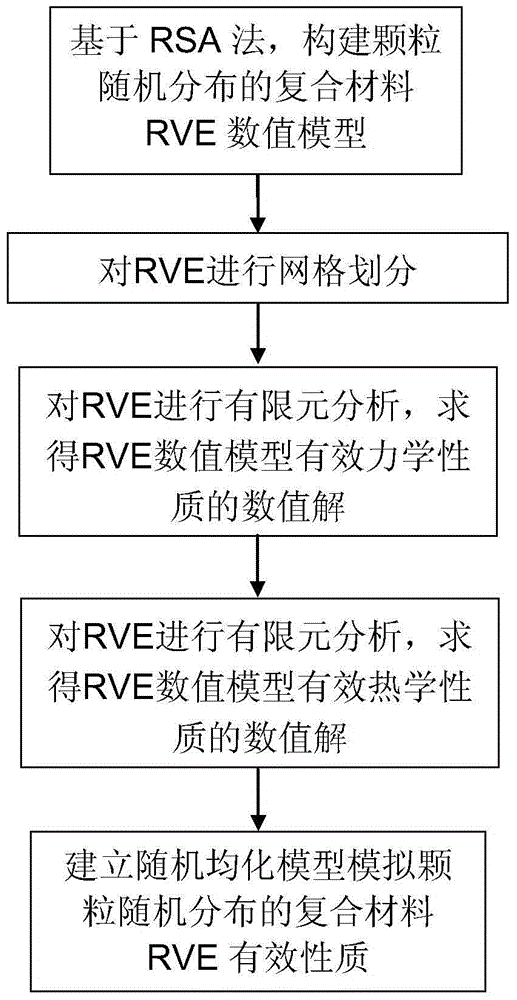

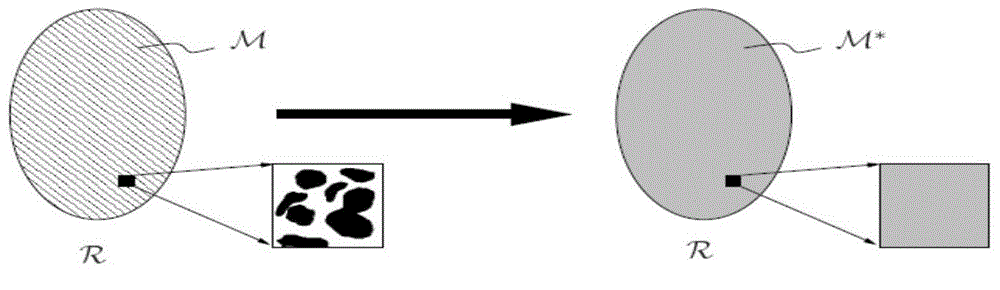

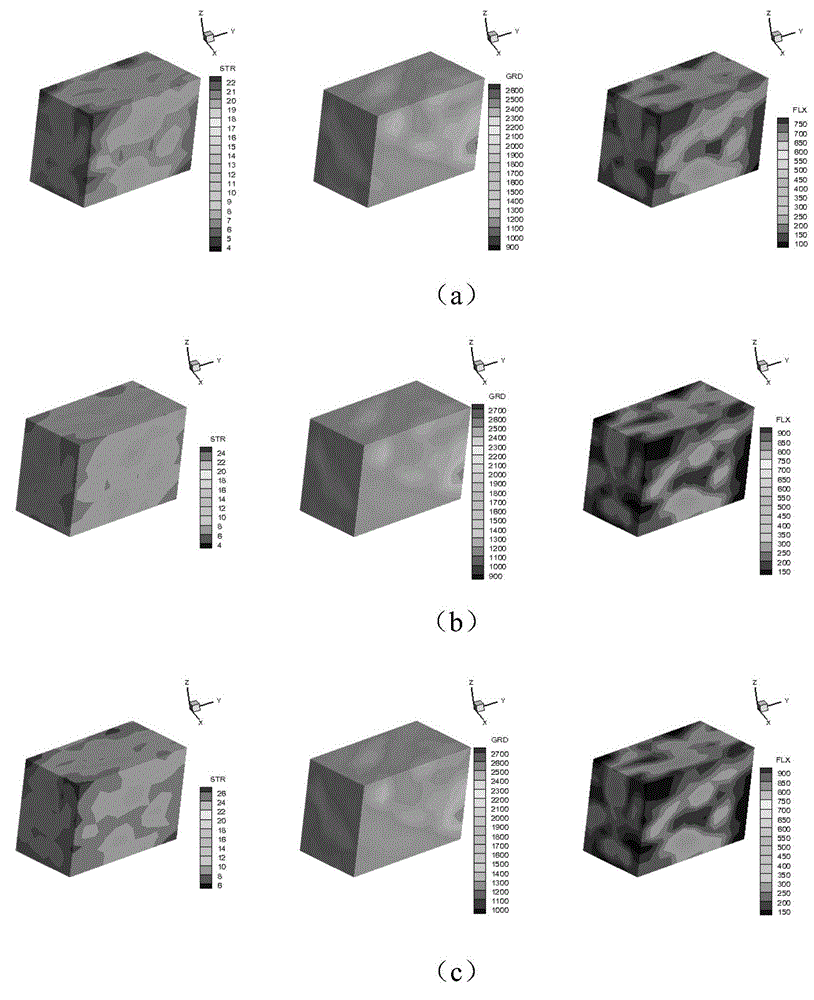

[0083] like figure 1 As shown, the present invention mainly has three main processes. First, a three-dimensional RVE (representational volume element) model of randomly distributed particles was constructed based on random sequence addition method (RSA) using FORTRAN language. At the same time, on the basis of the finite element method, the numerical solution of the macroscopically effective quantity of the material under linear boundary conditions was obtained through the Monte Carlo simulation method, a stochastic homogenization model was established to solve the macroscopically effective properties of the composite material, and the internal deformation of the RVE was drawn 3D distribution plot of gradient field, stress field, and heat flow field. The specific technical scheme is as follows:

[0084] 1. Construct a random RVE numerical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com