Epoxy resin/carbon nanotube high-strength lightweight composite material, and preparation method thereof

A composite material and carbon nanotube technology, which is applied in the field of epoxy resin/carbon nanotube high-strength and light-weight composite material and its preparation, can solve problems such as expensiveness and complexity, and achieve the effects of reducing density, improving mechanical strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

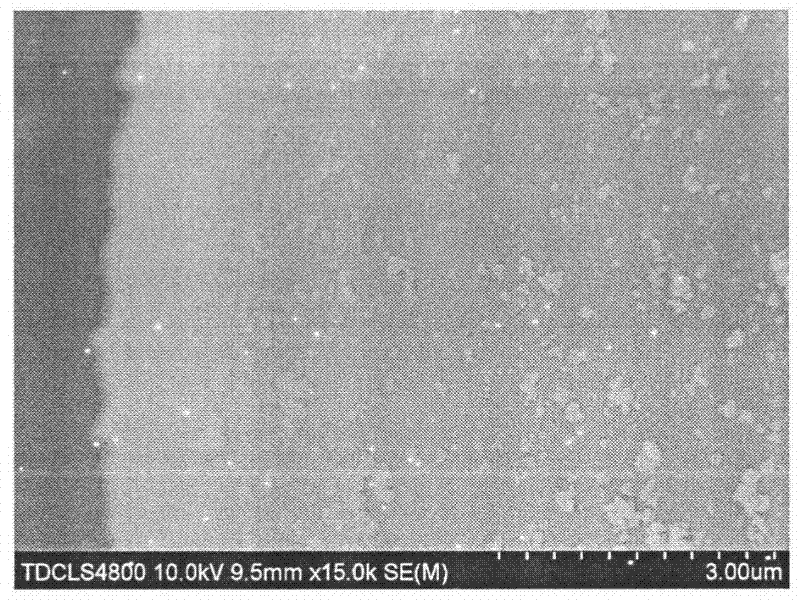

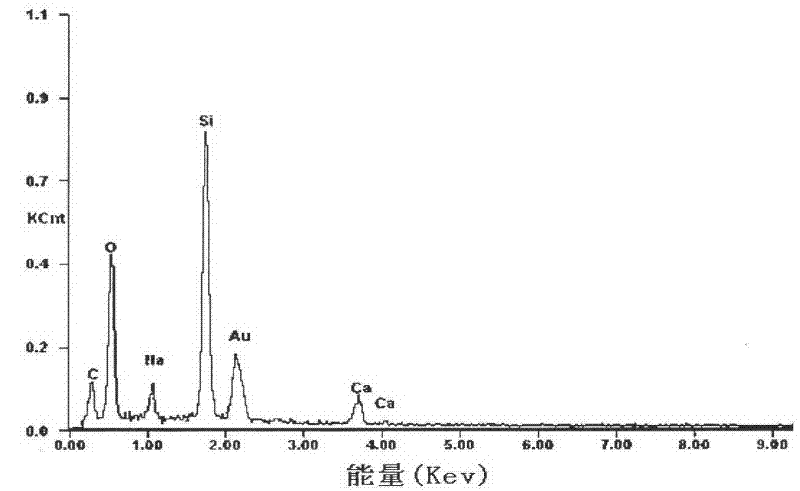

[0018] Example 1: 0.75g γ-aminopropyl triethoxysilane coupling agent is fully dispersed in the mixed solution of 150g ethanol / distilled water (volume ratio 9: 1), then 40g average particle diameter is 35 μ m, true density is 0.57g / cm 3 The hollow glass microspheres soaked in it for 24 hours and then filtered, and then dried in a blast drying oven at 120°C for 2 to 4 hours, and amino groups were introduced on the surface; at the same time, 1g of The carboxylated multi-walled carbon nanotubes (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, model TNMC5) were ultrasonically dispersed in 300g of DMF, the ultrasonic time was 10h, and the power was 200W; then the aminated hollow glass microspheres were added to the DMF In the system, react at 145°C for 12h to complete the grafting reaction, wherein the stirring rate is 200~500r / min; the above product is filtered and washed 3 times with ethanol, dried and added to a total weight of 130g epoxy resin (U.S. Dow Chemica...

example 2

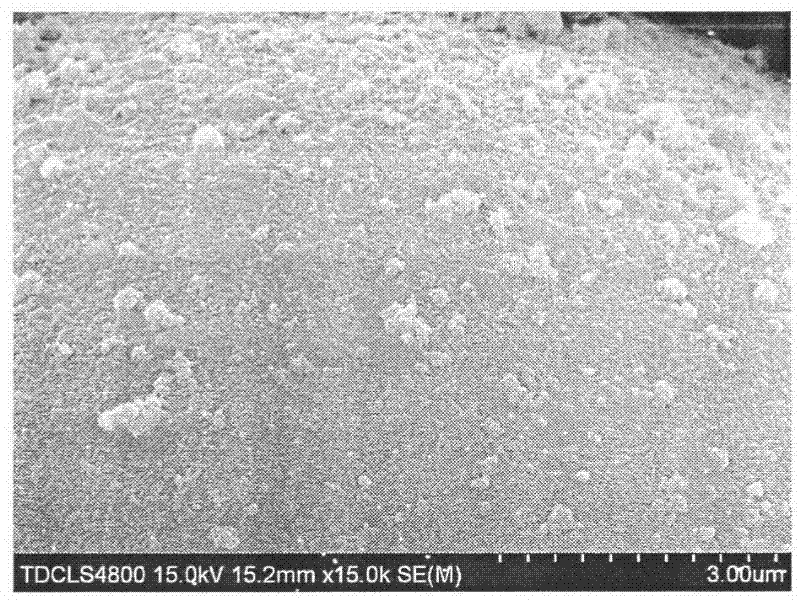

[0019] Example 2: Fully disperse 1.5g of γ-aminopropyltrimethoxysilane coupling agent in a mixed solution of 150g of ethanol / distilled water (volume ratio 9:1), then 10g of g / cm 3 The hollow glass microspheres were soaked in it for 24 hours and then filtered, and then dried in a blast drying oven at 120°C for 2 to 4 hours, and amino groups were introduced on the surface; at the same time, 3g of The carboxylated double-walled carbon nanotubes (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, model TNSDC) were ultrasonically dispersed in 300g of DMF, the ultrasonic time was 5h, and the power was 200W; then the aminated hollow glass microspheres were added to the DMF In the system, react at 120°C for 12 hours to complete the grafting reaction, and the stirring rate is 200-500r / min; filter the above product and wash it with ethanol for 3 times, dry it and add it to a mixture of epoxy resin and curing agent with a total weight of 130g In the system, mechanically s...

example 3

[0020] Example 3: Fully disperse 1g of γ-aminopropyltriethoxysilane coupling agent in a mixed solution of 150g of ethanol / distilled water (volume ratio 9:1), and then 50g of g / cm 3 The hollow glass microspheres were soaked in it for 24 hours and then filtered, and then dried in a blast drying oven at 120°C for 2 to 4 hours to introduce amino groups on the surface; at the same time, 5 g of The carboxylated multi-walled carbon nanotubes were ultrasonically dispersed in 300g of DMF, the ultrasonic time was 10h, and the power was 200W; then the aminated hollow glass microspheres were added to the DMF system and reacted at 145°C for 12h to complete the grafting reaction, wherein the stirring rate is 200 ~ 500r / min; the above product is filtered and washed with ethanol for 3 times, dried and added to the mixed system of epoxy resin and curing agent with a total weight of 130g, mechanically stirred at 1000r / min for 5min and then placed in Vacuum at 50°C to remove air bubbles, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com