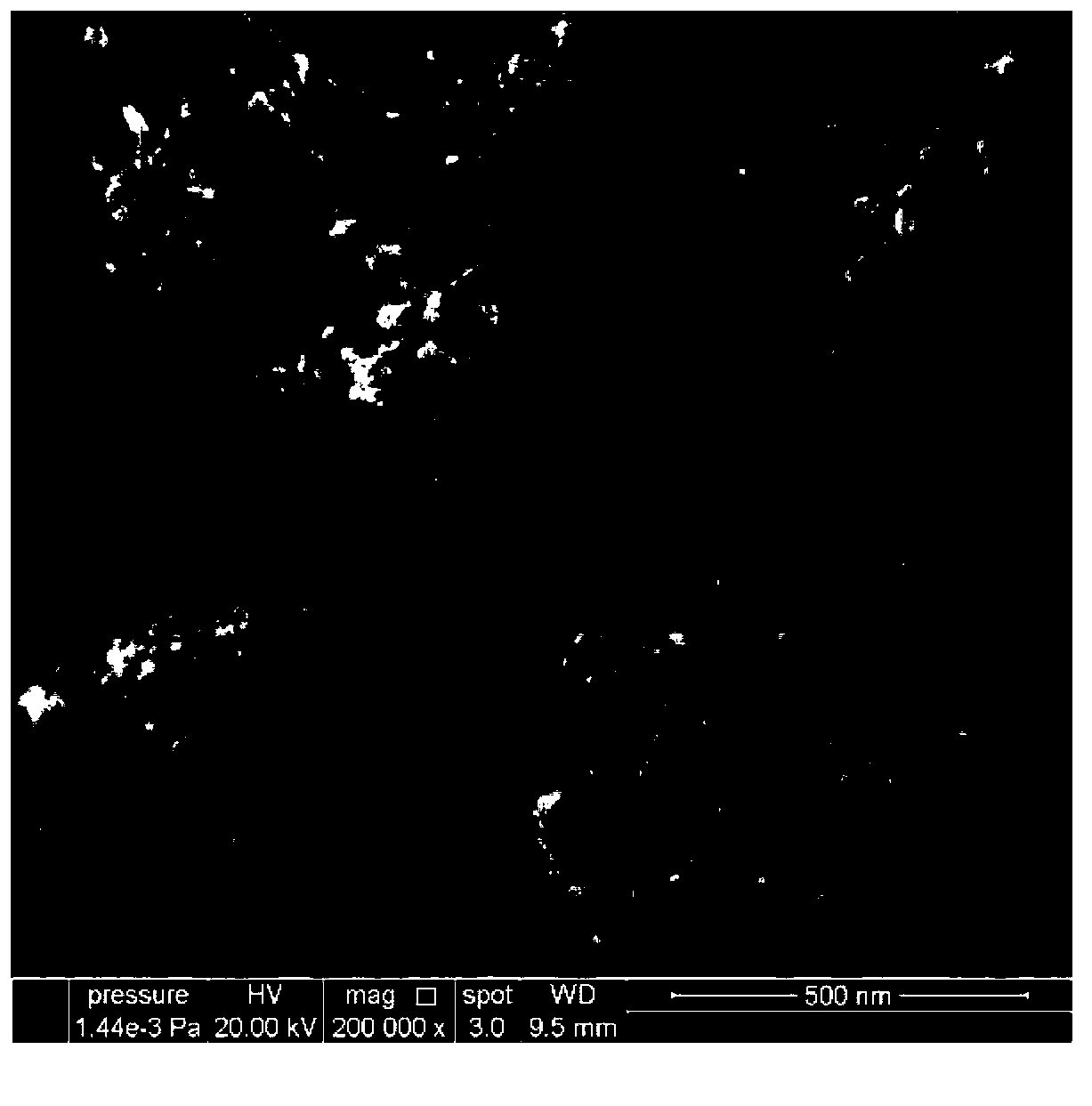

Preparation method of inorganically filled lithium ion battery diaphragm

A lithium-ion battery, inorganic filling technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of easy agglomeration of inorganic ions, inability to increase the heat resistance temperature, poor compatibility of matrix resin, etc., to improve mechanical properties. and heat resistance, ensuring uniformity, and the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

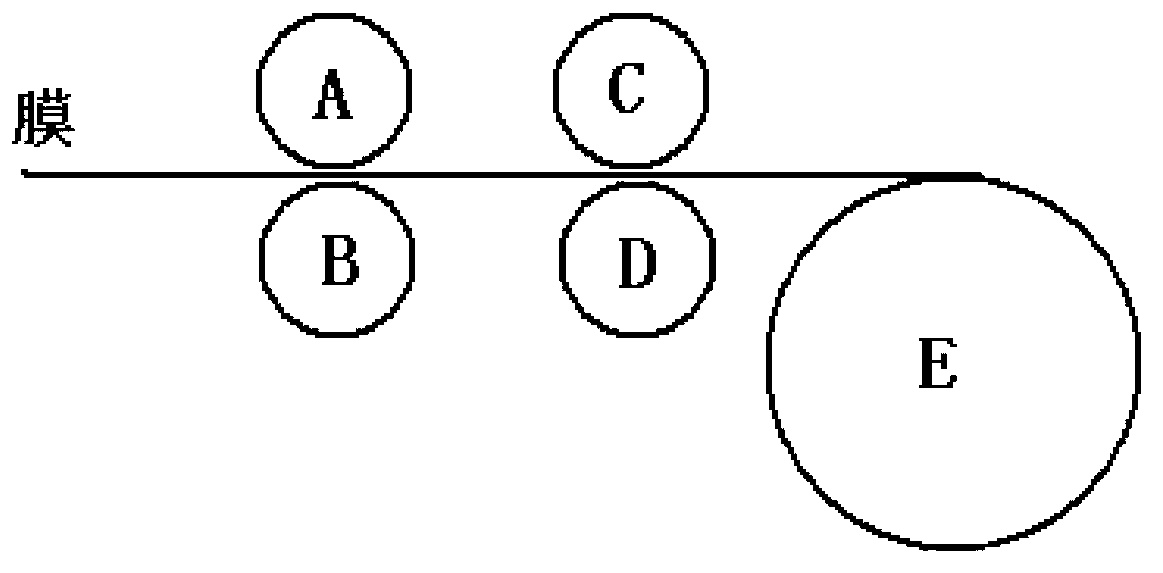

[0022] The present invention has the preparation method of the lithium-ion battery separator of inorganic filling and comprises the following steps:

[0023] Step 1: Mix and stir the ultra-high molecular weight polyethylene resin and diluent in a high-speed disperser at a mass ratio of 1:4-9 for at least 1 hour to ensure that the polyethylene particles are evenly dispersed in the suspension;

[0024] Step 2: Add tetrabutyl titanate to the ultra-high molecular weight polyethylene resin at a mass ratio of 0.1 to 1.2:1, add tetrabutyl titanate to the solution prepared in step 1, and continue stirring at high speed for 0.5 h;

[0025] Step 3: Stretching and extraction washing after extrusion into film,

[0026] Transfer the solution obtained in step 2 to the twin-screw extruder through a pump, and set the heating temperature of the twin-screw extruder in zones 1-2, 3-6, 7-8, and 9 to 215°C and 225°C respectively , 220°C, 210°C, extruded into film, and cooled by three rolls;

[0...

Embodiment 1

[0037]Add 15 parts by weight of ultra-high molecular weight polyethylene (viscosity average molecular weight 2,500,000), 0.5 parts by weight of 168 antioxidant, 0.5 parts by weight of 1010 antioxidant, and 80 parts by weight of white oil into a high-speed disperser, and mix at 800rpm at room temperature 1 hour. Then add 5 parts of tetrabutyl titanate, adjust the rotational speed of the disperser to 1200 rpm, mix for 0.5 hours and then add the material into the twin-screw extruder. The temperature of each zone of the extruder is set at 215°C, 225°C, 220°C, and 210°C. The extruded film is stretched 6×6 and sent to the circulating water tank. Then the film was heat-treated at 125°C for 5 minutes, and sent to a 25 μm, 130°C thermal calendering process, and the film after two calendering was wound up.

Embodiment 2

[0039] Add 15 parts by weight of ultra-high molecular weight polyethylene (viscosity average molecular weight 2,500,000), 0.5 parts by weight of 168 antioxidant, 0.5 parts by weight of 1010 antioxidant, and 75 parts by weight of white oil into a high-speed disperser, and mix at 800rpm at room temperature 1 hour. Then add 10 parts of tetrabutyl titanate, adjust the rotation speed of the disperser to 1200 rpm, mix for 0.5 hours, and then add the material into the twin-screw extruder. The temperature of each zone of the extruder is set at 215°C, 225°C, 220°C, and 210°C. The extruded film is stretched 6×6 and sent to the circulating water tank. Then the film was heat-treated at 125°C for 5 minutes, and sent to a 25 μm, 130°C thermal calendering process, and the calendered film was wound up.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com