High-performance gas sensor

A gas sensor, sensor technology, applied in the direction of material resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Raw materials for material preparation: zinc acetate, sodium hydroxide, sodium citrate, ethylenediamine, absolute ethanol, deionized water, lanthanum nitrate.

[0016] Equipment used for material preparation: 50mL beaker, 250mL beaker, measuring cylinder, glass rod, key, rubber dropper, magnetic stirrer, high-speed centrifuge.

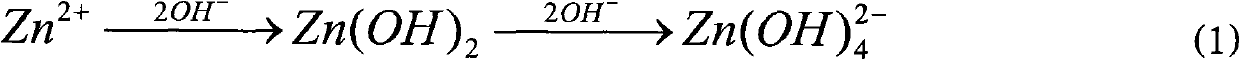

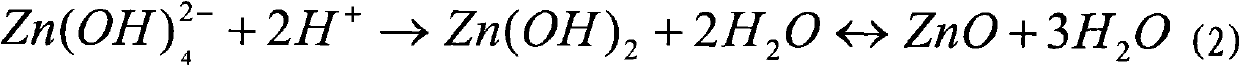

[0017] This patent application simply prepares ZnO nanomaterials under normal temperature and pressure conditions, and prepares doped La 2 o 3 ZnO nanomaterials. The prepared gas sensor is very sensitive to alcohol gas and can be used as an alcohol detector for traffic police. The gas sensor prepared by the latter material has higher sensitivity and faster response / recovery time for the detection of alcohol gas. The gas sensor made of the latter material has higher sensitivity to acetone gas, and can selectively detect acetone gas in industrial production. Therefore, the experimentally prepared La-doped 2 o 3 ZnO nanomaterials have potenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com