Method for preparing bone-like apatite controlled by thermodynamics

A kind of bone apatite, thermodynamic control technology, applied in chemical instruments and methods, medical science, phosphorus compounds, etc., can solve the problems of high requirements of reaction conditions, unstable product composition, difficult control of process parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

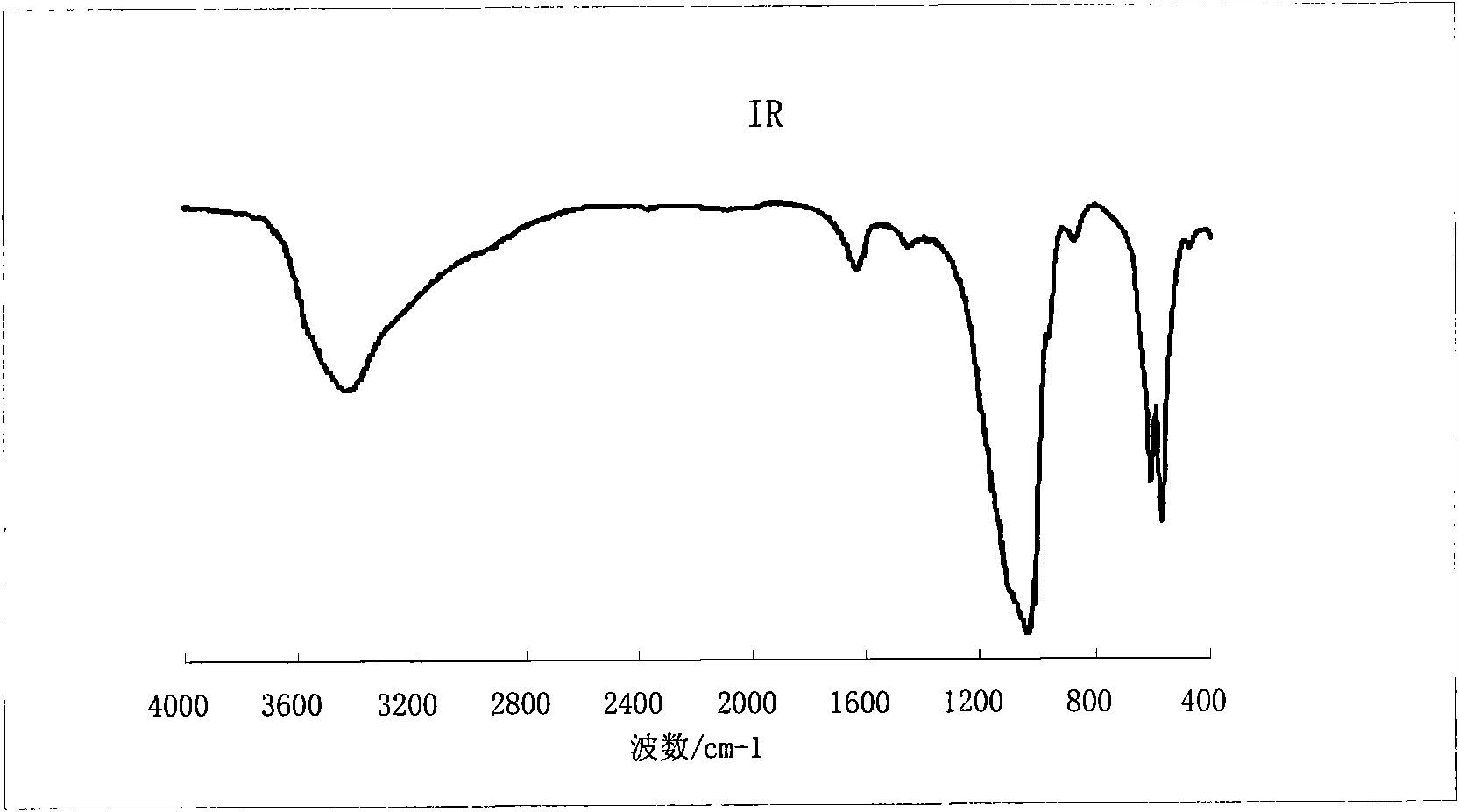

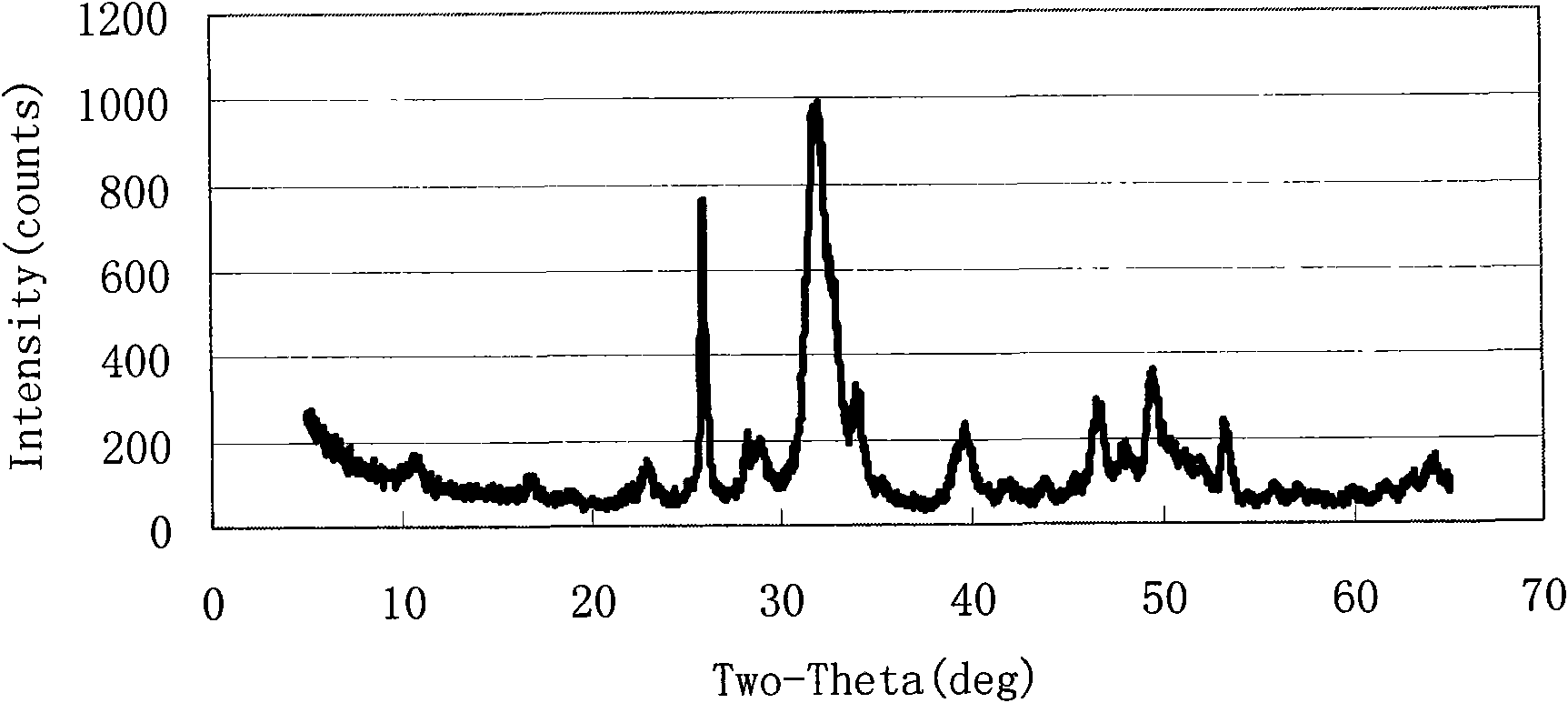

[0024] Get 456g of trisodium phosphate dodecahydrate and add it into 3000 milliliters of deionized water to make a solution, add 345g of calcium sulfate dihydrate under stirring condition, and keep stirring to make it react. At the same time, 0.2 g of sodium bicarbonate was added to adjust the pH of the reaction system to 7, and the reaction system was reacted at 20° C. for 8 hours, then the stirring was stopped, and the mixture was left to age at room temperature for 48 hours. After aging, the supernatant was removed and washed at least 6 times with deionized water at 60°C. After washing, prepare a slurry with a water content of 70%. After the prepared slurry is dried at 80° C. to 100° C., infrared absorption spectrum (IR) and X-ray diffraction (XRD) analysis and calcium / phosphorus ratio detection are performed.

[0025] The test results are as follows:

[0026] 1. The calcium / phosphorus ratio in the prepared nano-apatite is 1.64, which is in line with the ratio of calcium ...

Embodiment 2

[0032] Get 380g of trisodium phosphate dodecahydrate and add it into 3000 milliliters of deionized water to make a solution, add 258g of calcium sulfate dihydrate under stirring condition, and keep stirring to make it react. At the same time, 0.16 g of sodium bicarbonate was added to adjust the pH of the reaction system to 7. After reacting at 20° C. for 8 hours, the stirring was stopped, and the reaction system was aged at room temperature for 48 to 72 hours. After aging, remove the supernatant and wash with deionized water at 60°C for at least 6 times. The yield reaches 98.5%. After the slurry was dried, the calcium-to-phosphorus ratio was tested to be 1.53.

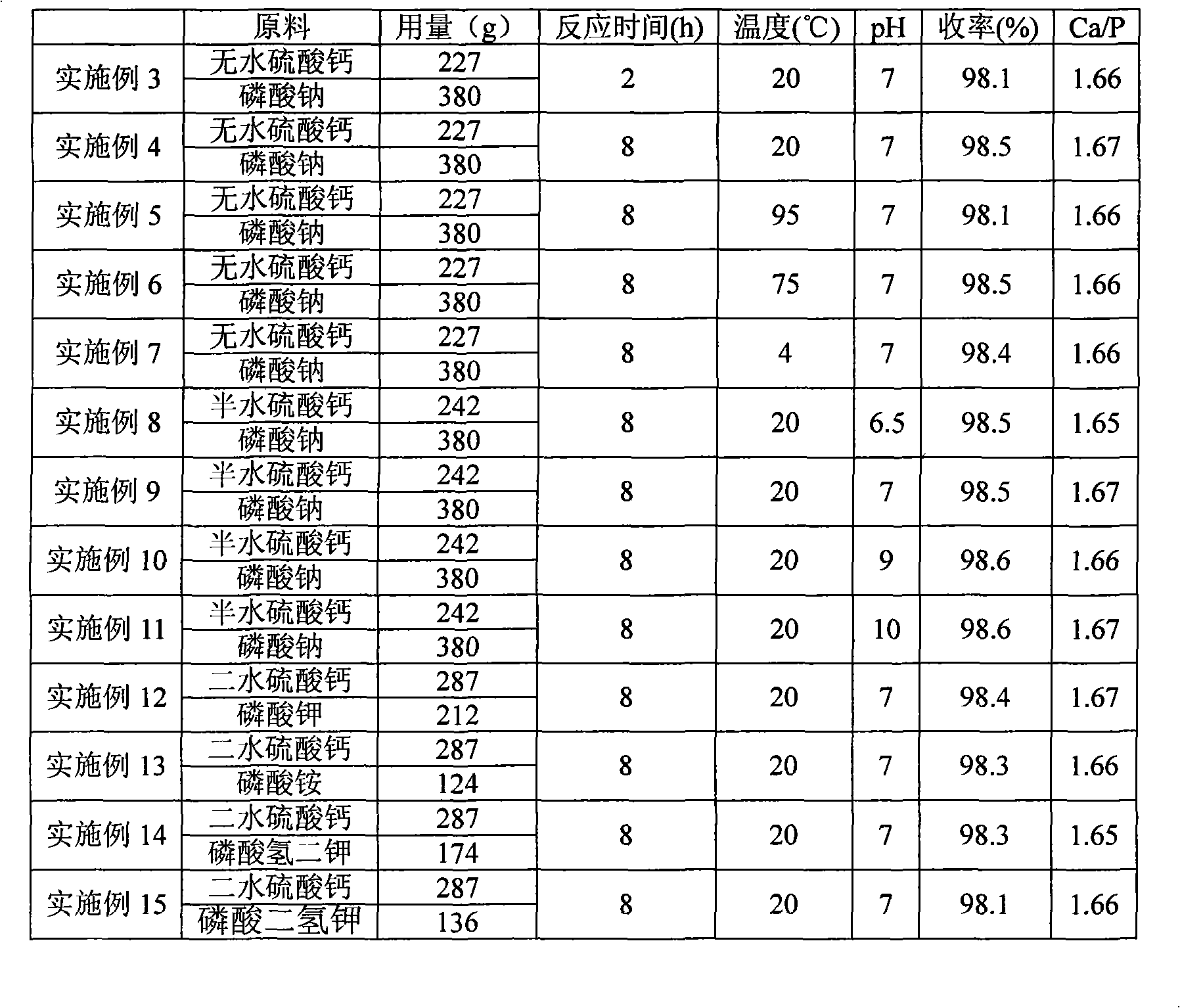

Embodiment 3~12

[0034] Add different phosphates from the table below to 3000 ml of deionized water to make a solution, add calcium salt under stirring conditions, and keep stirring to make it react. At the same time, sodium bicarbonate was added to adjust the pH of the reaction system. After the reaction was completed, the stirring was stopped, and the mixture was aged at room temperature for 48 hours. After aging, remove the supernatant, and wash at least 6 times with deionized water at 60°C. Yields and Ca-P ratios are shown in Table 2.

[0035] The relevant parameter of table 2 embodiment 3~12

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com