Method for welding between metal plates

A welding method and technology for metal plates, applied in the welding process and the field of welding between metal plates, can solve the problems of high equipment dependence and troublesome experiments, and achieve the effect of solving insufficient heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Select nickel powder with a purity of more than 99.5% and a particle size of 100-200 mesh, aluminum powder with a purity of more than 99% and a particle size of 100-200 mesh, control the powder-to-material ratio of nickel and aluminum to 30:59, and the total amount of mixed powder to be 20g.

[0030] The QM32 planetary ball mill is used for ball milling, stainless steel balls are used as the grinding medium, and the ball-to-material ratio is 10:1. In order to prevent the powder from being oxidized during the ball milling process, the ball mill tank is evacuated and argon is introduced for protection. The ball milling speed is 350-450rpm, and the ball milling time is 35-45h to obtain nickel-aluminum mixed powder in a metastable state.

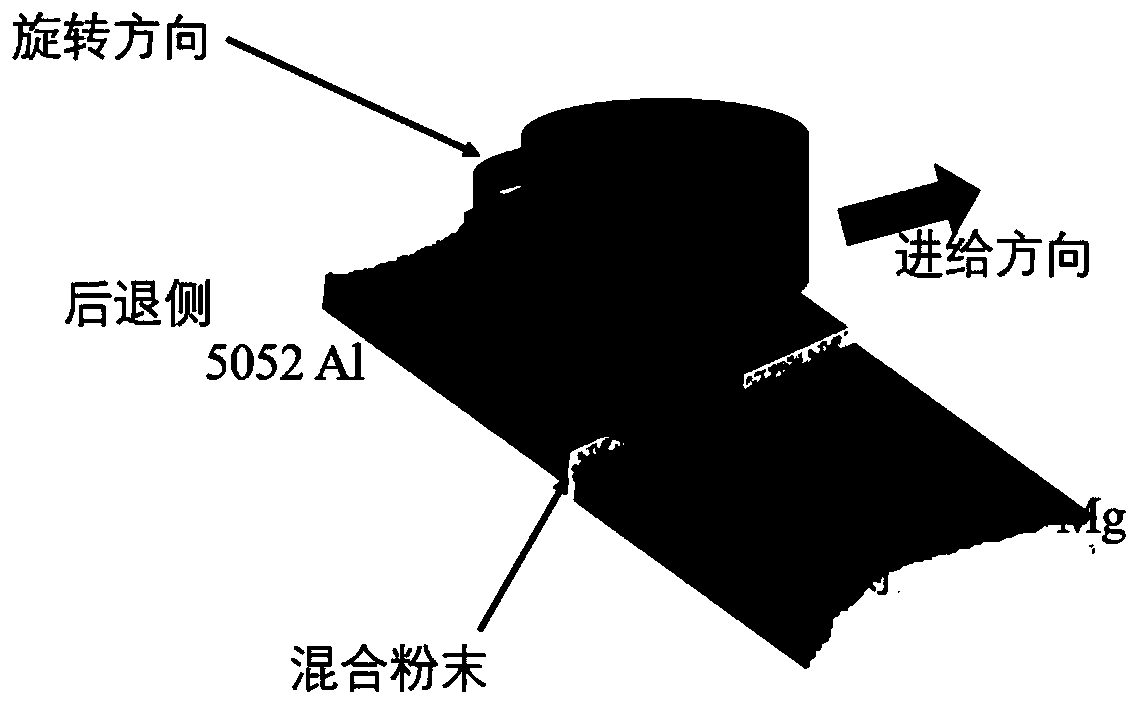

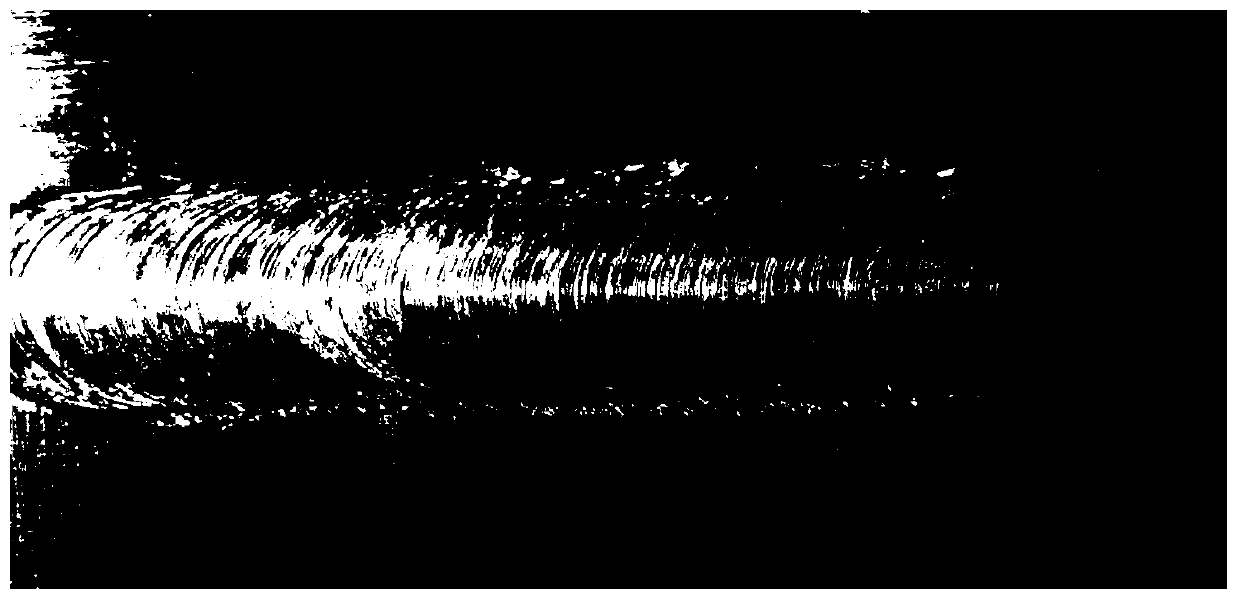

[0031] Friction stir welding lap welding is adopted, and the welding process is determined as follows: rotation speed 700-1500rpm, feed speed 50mm / min, downforce control to 4KN-6KN, stirring needle length is slightly shorter than the upper...

Embodiment 2

[0034] Select nickel powder with a purity of more than 99.5% and a particle size of 100-200 mesh, aluminum powder with a purity of more than 99% and a particle size of 100-200 mesh, and control the powder-to-material ratio of nickel and aluminum to 27:59.

[0035] The QM32 planetary ball mill is used for ball milling, stainless steel balls are used as the grinding medium, and the ball-to-material ratio is 10:1. In order to prevent the powder from being oxidized during the ball milling process, the ball mill tank is evacuated and argon is introduced for protection. The ball milling speed is 350-450rpm, the ball milling time is 35-45h, and the nickel-aluminum mixed powder in a metastable state is obtained.

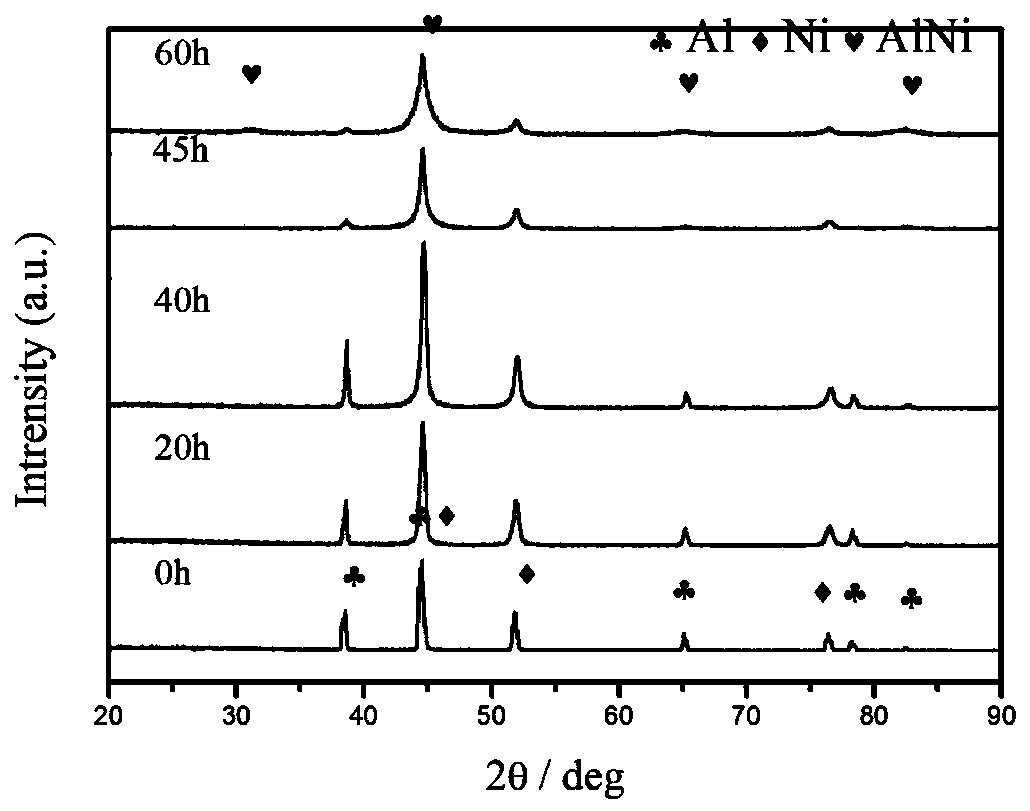

[0036] image 3 It is a graph of XRD detection results of ball milling at different times in Example 2 of the present invention; it can be seen from the figure that the mixed powder has not reacted after ball milling for 35-45 hours, and the mixed powder has reacted to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com