Method for preparing hydrogen from methanol

A technology for methanol preparation and hydrogen, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as environmental pollution and depletion of fossil resources, and achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

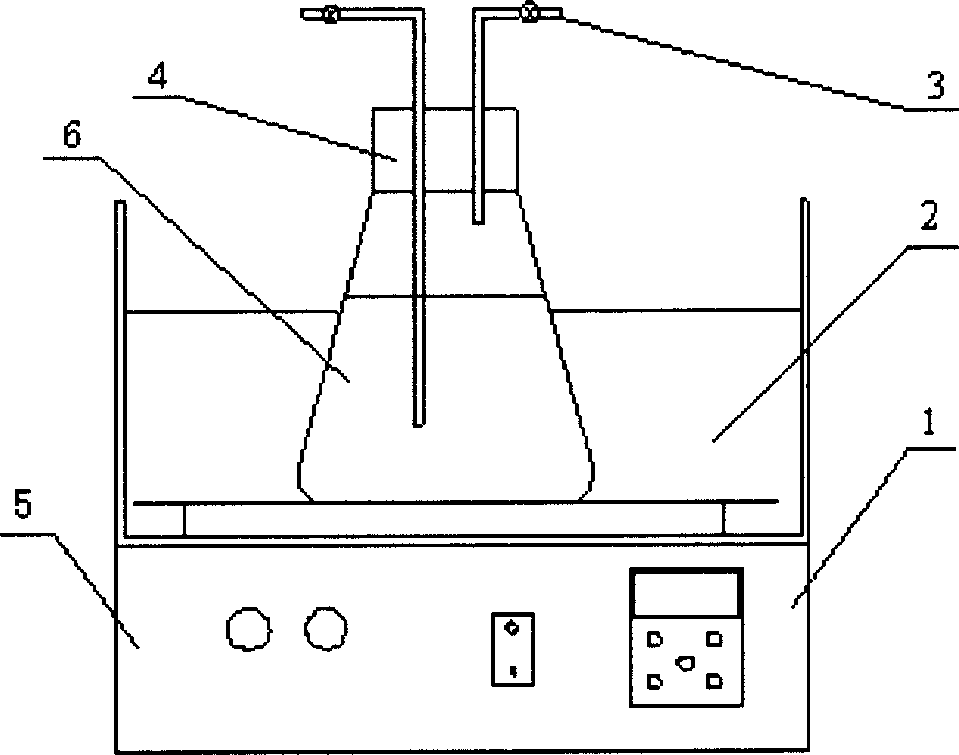

[0023] see figure 1 , the experimental device of the present invention comprises a tank 5 with an ultrasonic generator 1, a coupling liquid 2 is contained in the tank 5, a bottle 6 of methanol solution is placed in the coupling liquid 2, the bottle 6 Sealed by the rubber stopper 4, and the rubber stopper 4 is also provided with a sampling port 3 communicated with the bottle body 6. In the experiment, the airtight bottle body 6 reserves a certain space. Under the same state as the temperature before the reaction, ignore The slight pressure change caused by gas generation in the reactor is detected by gas chromatography. In this way, when the volume of generated gas is measured by the drainage method, the large detection error caused by the relatively complicated experimental system and the small amount of hydrogen generated can be avoided. In addition, N is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com