Modified gelatin fiber

A technology of gelatin and fiber, which is applied in the field of fiber manufacturing, can solve the problems of limiting the application of gelatin, failing to fully reflect the excellent properties of gelatin materials, and adding a large amount of modifiers, so as to achieve simple process, low requirements for production equipment, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

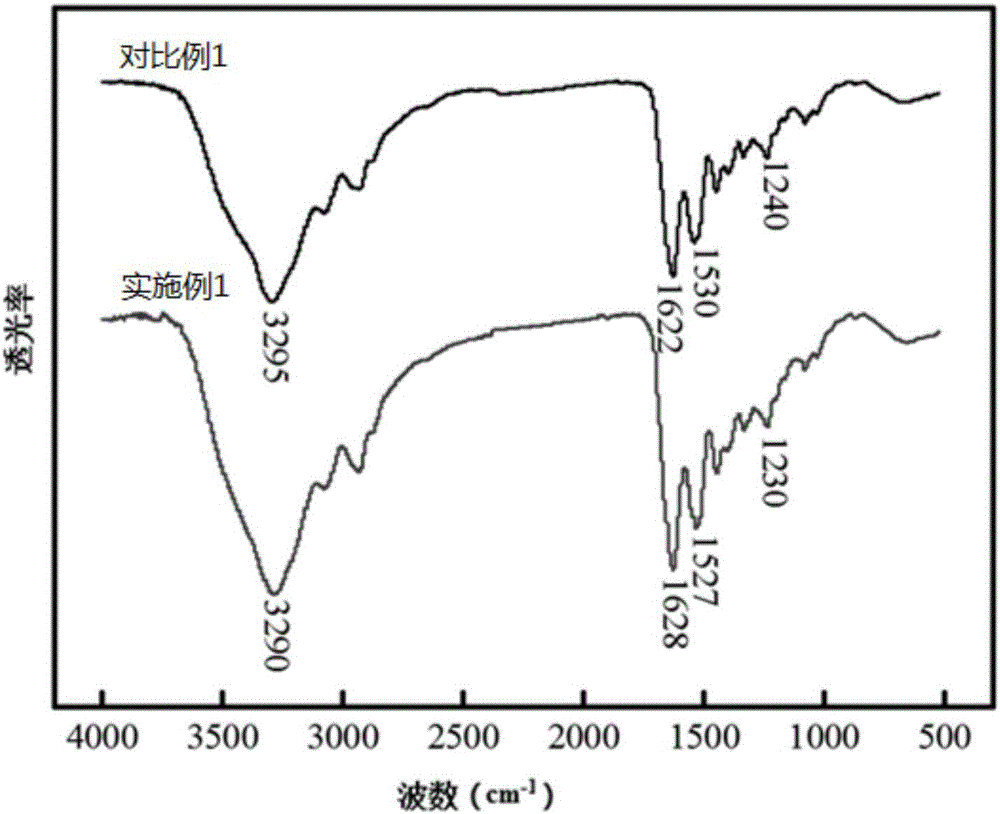

Embodiment 1

[0077] Step 1, weigh 220 g of gelatin and add it to a beaker filled with 380 mL of water, let it swell in a water bath at 60° C. for 1 h, then stir for 3 h to obtain a gelatin solution; add 0.44 g of TGase enzyme (0.2% gelatin mass) to the gelatin solution %), stirred at 60°C for 1h to obtain spinning dope;

[0078] Step 2, the spinning stock solution is added to the spinning machine, and after vacuum degassing for 2h, enter the coagulation bath from the spinneret with a micropore diameter of 0.09mm to solidify to obtain the primary fiber fiber, and the coagulation bath is 430g of TGase enzyme containing 5% (weight). / L of sodium sulfate aqueous solution, the temperature of the coagulation bath is 40°C, and the spinning speed is 80 m / min;

[0079] Step 3, the as-spun fiber is drawn 3 times at 25°C, and the drawing speed is 180m / min, to obtain the drawn gelatin fiber;

[0080] In step 4, the cross-linking treatment of the stretched gelatin fiber at a cross-linking solution con...

Embodiment 2~4

[0082] The operation steps are the same as in Example 1, the difference is only to change the amount of TGase enzyme added in the cross-linking bath in step 4, the mass concentration of TGase enzyme in the cross-linking bath is respectively 3%, 4% and 5%, and the obtained The finished product gelatin fiber is numbered successively as 2# (embodiment 2), 3# (embodiment 3) and 4# (embodiment 4).

Embodiment 5~7

[0084] Operation steps are identical with embodiment 2, and difference is only to change the cross-linking time in step 4 to be respectively 0.5h, 1.5h and 2.0h, and the finished product gelatin fiber that obtains is numbered successively as 5# (embodiment 5), 6# (implementation) Example 6) and 7# (embodiment 7).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com