Hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition

A thermoplastic polyester and polyester elastomer technology, which is applied in the field of thermoplastic polyester elastomer compositions, can solve problems such as poor hot water resistance, inability to fully maintain tensile strength and elongation at break, and easy gelation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

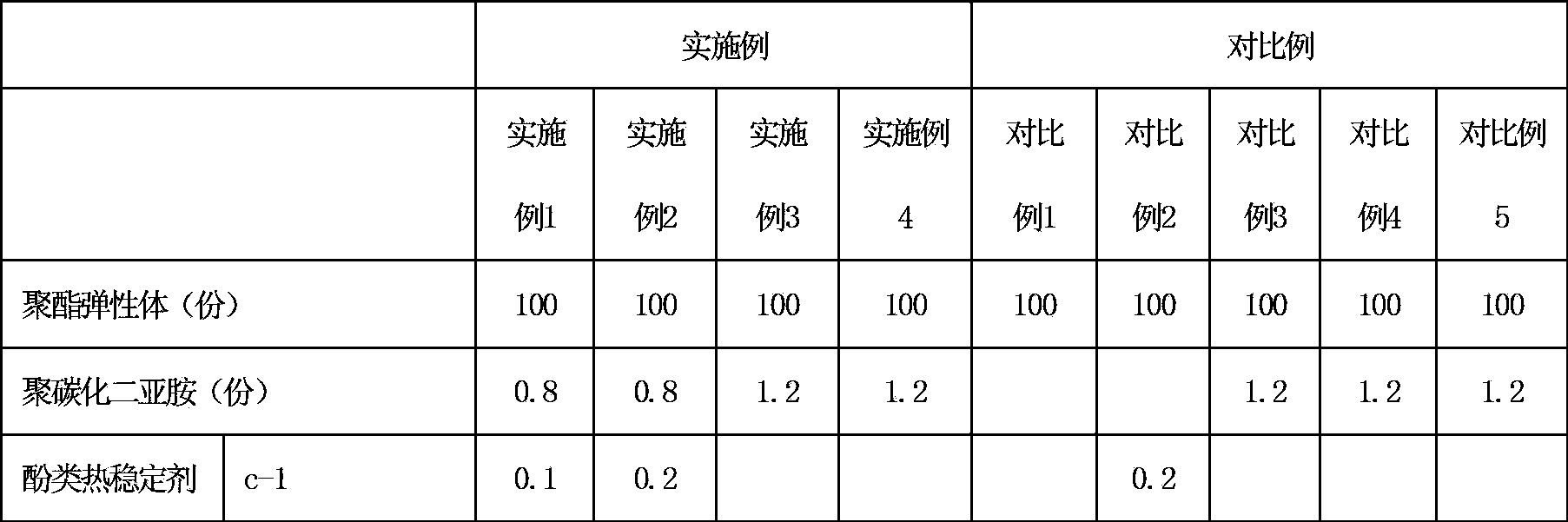

[0145] Mix polyester elastomer (A), polycarbodiimide (B), phenolic heat stabilizer (C), and thioester heat stabilizer (D) according to the compounding ratio (unit: parts by weight) recorded in Table 1 , Aromatic amine heat stabilizer (E). Then use the TSSJ-25 twin-screw extruder produced by Sichuan Chenguang Plastic Machinery Research Institute to melt, knead and extrude at 230 ° C. After cooling the obtained strands in a water tank, they are sheared with a pelletizer to obtain Granules of polyester elastomer composition. The obtained granules were dried at 100°C for 4 hours.

[0146] Using the above-mentioned pellets, a tensile test piece was molded at 240° C. by an injection molding machine.

[0147] The specific experiments and conclusions are shown in the table below.

[0148] Table 1

[0149]

[0150]

[0151]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com