Halogen-free flame-retardant insulated wire

A technology for insulated wires and insulating layers, which is applied in the direction of insulated cables, insulators, insulated conductors, etc., and can solve the problems of reduced flexibility of insulating coating films, lower initial tensile elongation of insulating coating films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4 and comparative example 1 to 7

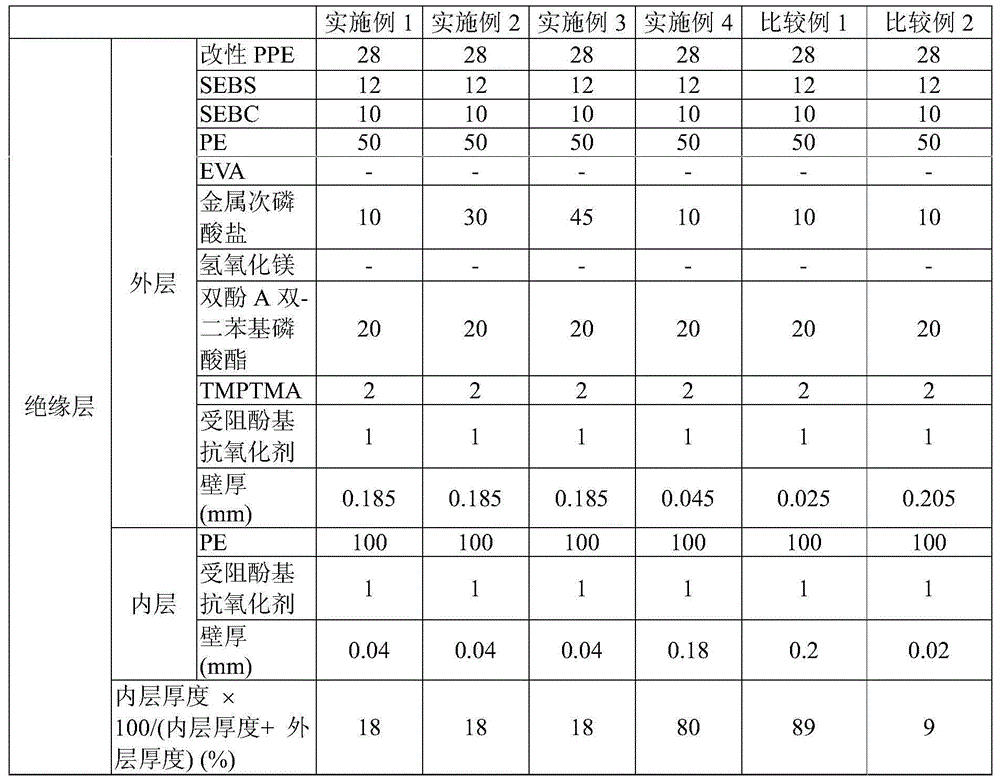

[0075] (Preparation of resin composition pellets)

[0076] The respective components for the outer and inner layers were mixed in the compositions shown in Tables I and II. The components were melt-mixed by using a twin-screw mixer (45 mmφ, L / D=42) at a cylinder temperature of 240° C. and a screw rotation number of 200 rpm. Each resulting mixture was melt extruded into strands. Subsequently, the molten strands were cooled and cut to prepare pellets.

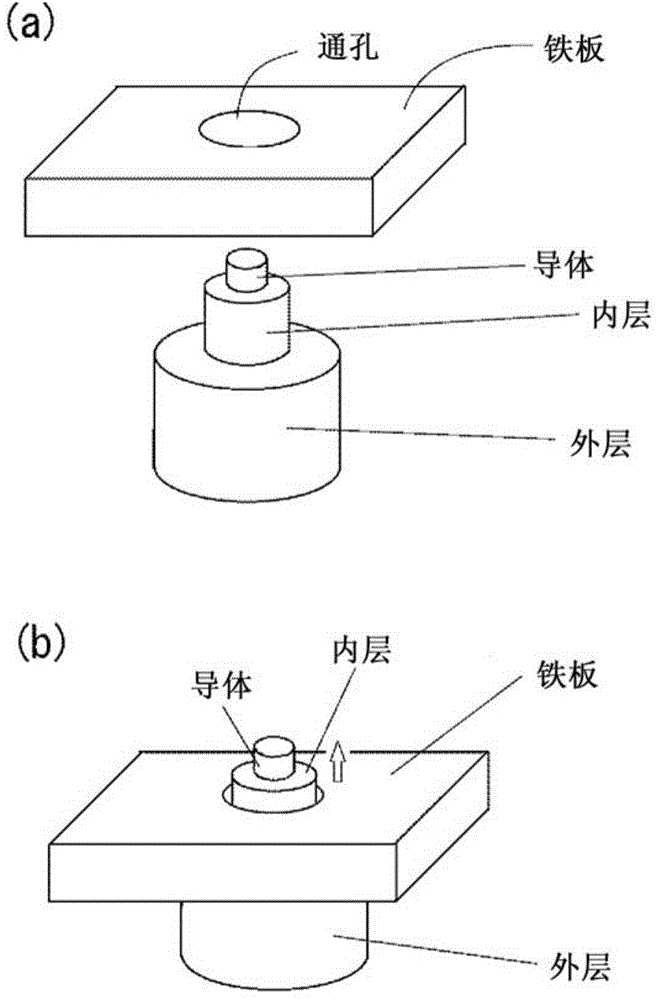

[0077] (Preparation of insulated wire)

[0078] Using a single-screw extruder (30mmφ, L / D=24), the resin for the inner layer was extruded to a cross-sectional area of 0.35mm in such a manner that the wall thicknesses shown in Table I and Table II were obtained. 2 Conductor (comprising 19 twisted wires of annealed copper wires, each copper wire having a diameter of 0.16mmφ) to form an inner layer. After cooling, the outer layer was formed by extruding the resin for the outer layer over the inner layer using the same single s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com