Fast change method of large-scale converter movable gas hood

A technology of movable hood and replacement method, which is applied in the direction of manufacturing converters, improving process efficiency, and improving energy efficiency. It can solve the problems of difficult adjustment angle, high construction cost, and long construction period, so as to improve operation safety. , to ensure the construction quality and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

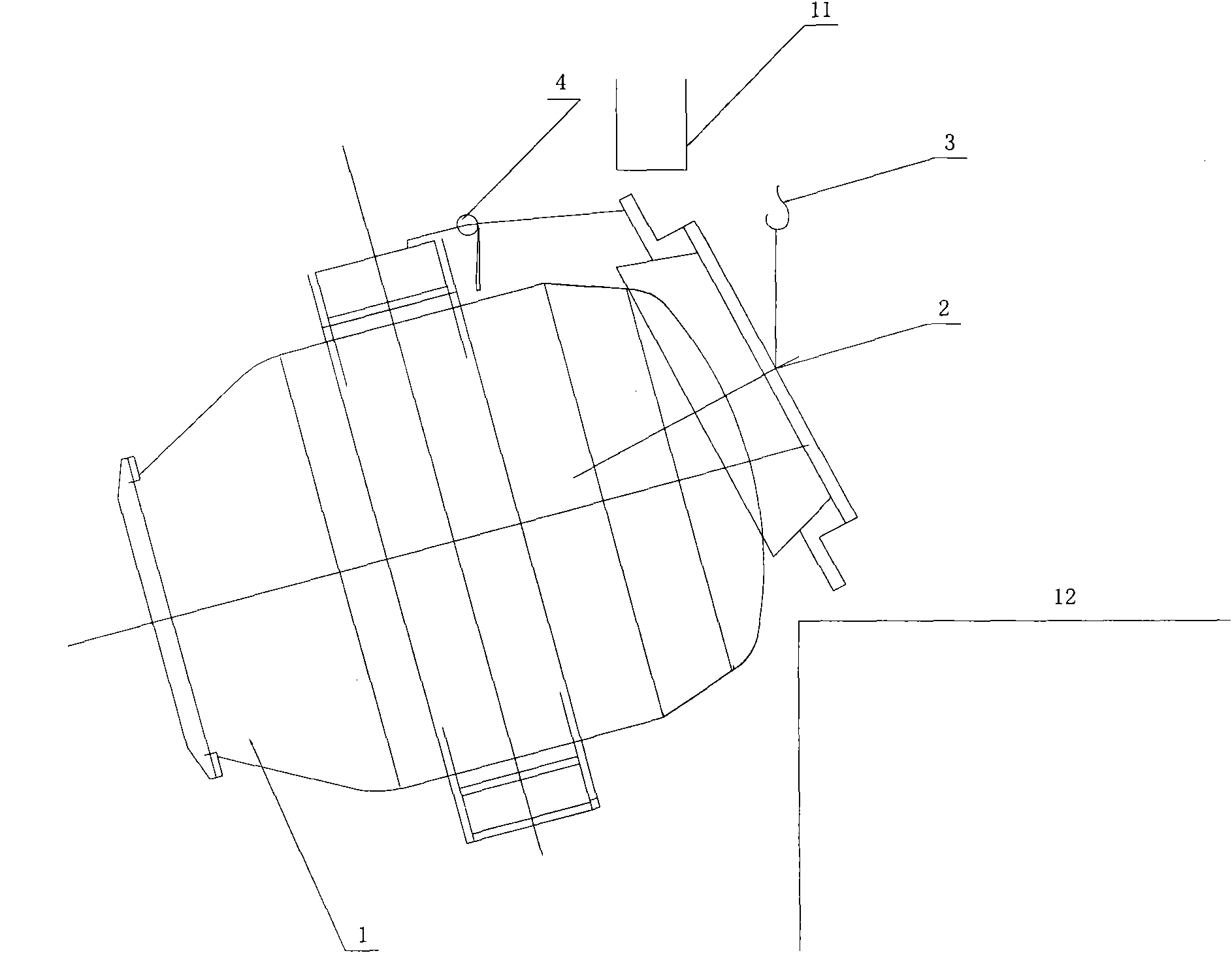

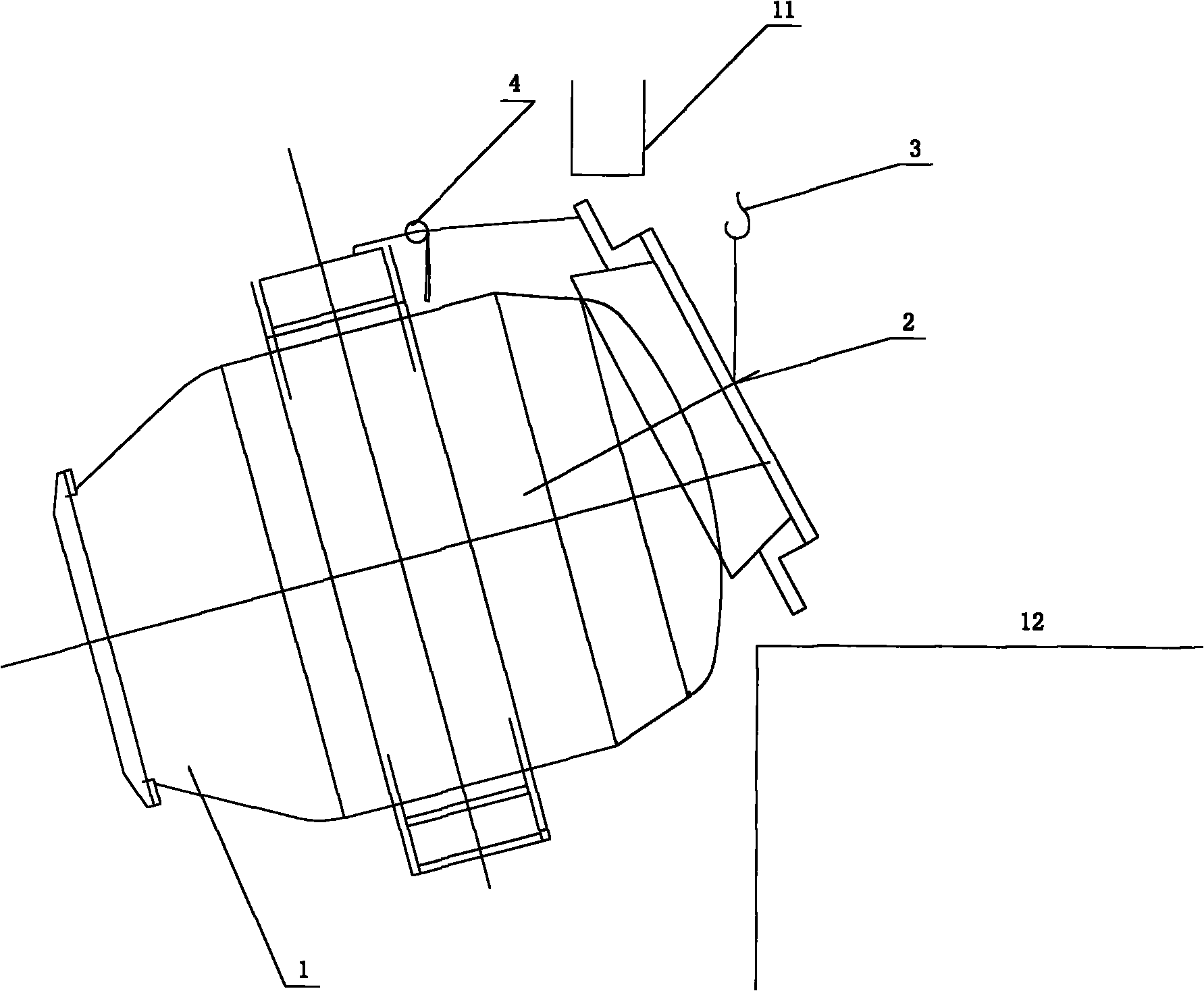

[0017] There is a converter 1, and the movable hood 2 needs to be replaced, such as figure 1 Shown. Follow the steps below in sequence:

[0018] a. Remove the fixed hood;

[0019] b. Remove the cooling water pipe of the movable fume hood 2, and shake the converter 1 until the bottom of the furnace is up;

[0020] c. Loosen the lifting chain of the lifting device of the movable fume hood 2, drop the movable fume hood 2 on the bottom of the furnace, and use the inverted chain 4 to fix the movable fume hood 2 on the converter 1. The inverted chain 4 used has a different lifting weight Less than 10 tons, this embodiment adopts a rewind chain with a lifting weight of 10 tons;

[0021] d. Then shake the converter 1 toward the front of the furnace, and swing the movable fume hood 2 to the position of the platform 12 in front of the converter. The platform 12 is 9.6 meters square, and the movable fume hood 2 is hoisted down with a crane 3;

[0022] e. Use the crane 3 to hoist the new movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com