Integrated monitoring device for conveying chain of coal sorting machine

A technology of comprehensive monitoring and conveying chain, applied in the direction of solid separation, comprehensive factory control, comprehensive factory control, etc., can solve the problems of unreliable operation, low sensitivity, imperfect functions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

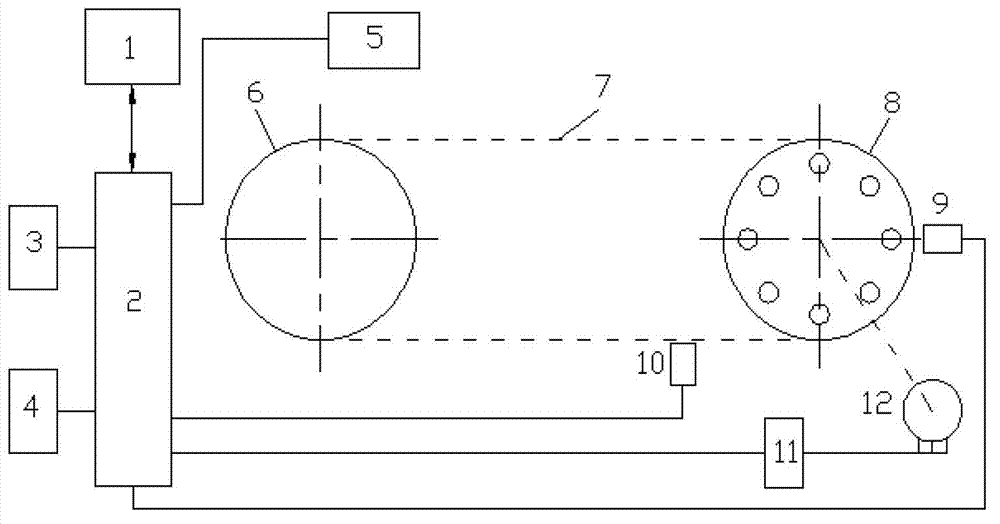

[0015] Example 1: figure 1 It is a structural diagram of the conveyor chain comprehensive monitoring device of the present invention. The conveyor chain comprehensive monitoring device includes a host monitoring computer 1, a main control unit 2, an external input circuit 3, a reset circuit 4, an alarm circuit 5, a driven wheel 6, a conveyor chain 7, a driving wheel 8, a speed detection unit 9, and a fault detection unit 10 , a motor control unit 11 and a drag motor 12.

[0016] The upper monitoring computer 1 forms a communication circuit with a communication cable and a link adapter, and communicates with the main control unit 2 bidirectionally. The external input circuit 3 , reset circuit 4 , speed detection unit 9 and fault detection unit 10 are respectively connected to the signal input end of the main control unit 2 . The external input circuit 3 realizes operations such as function selection, parameter adjustment, determination, and cancellation of the main control un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com