Longspan pipe truss pulling bar lifting and overhead rotating emplacing construction method

A construction method and technology of pipe trusses, which are applied in construction, building structure, processing of building materials, etc., can solve the problems of high cost, low work efficiency, high labor intensity, etc., and achieve the effect of low cost and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

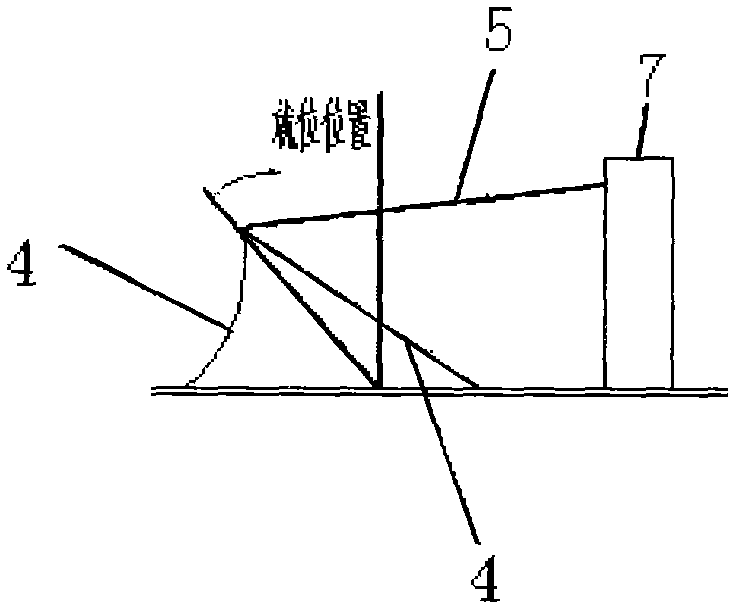

[0029] A construction method for lifting a large-span pipe truss by pulling out a rod and rotating it in the air, comprising the following steps:

[0030] (1) Fabrication and assembly of trusses

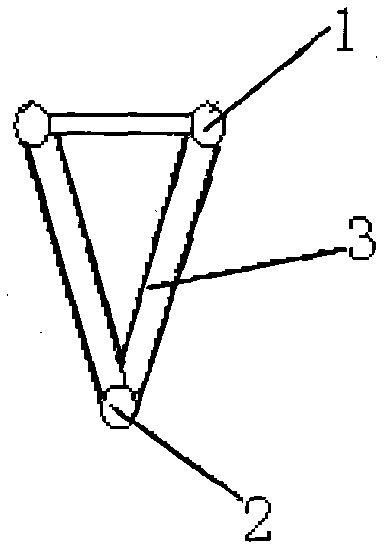

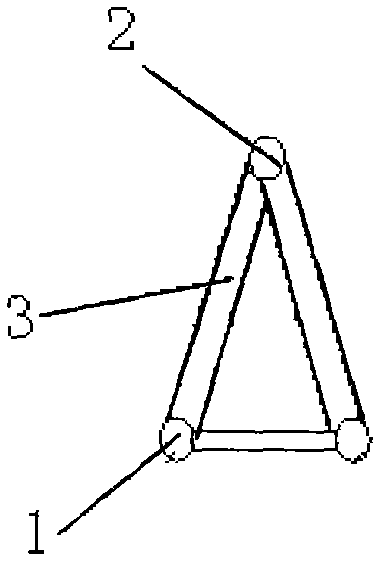

[0031] The truss is assembled from upper chord 1, lower chord 2, and diagonal web 3, and the appropriate upper chord 1, lower chord 2, and diagonal web 3 are selected according to the design, and the upper chord 1, lower chord 2, and diagonal web The rods 3 are respectively composed of pipe members. For the convenience of assembly, firstly put two upper chords 1 on the bottom and one lower chord 2 on the top. See figure 1 , after the assembly is completed, the truss can be rotated 180 degrees up and down, see figure 2 ;

[0032] When assembling, directly use the floor as the supporting platform, place the two upper chords 1 on the leveled floor, level it with a level, and check the pre-camber value through the level at the same time. When the pre-camber value: the difference betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com